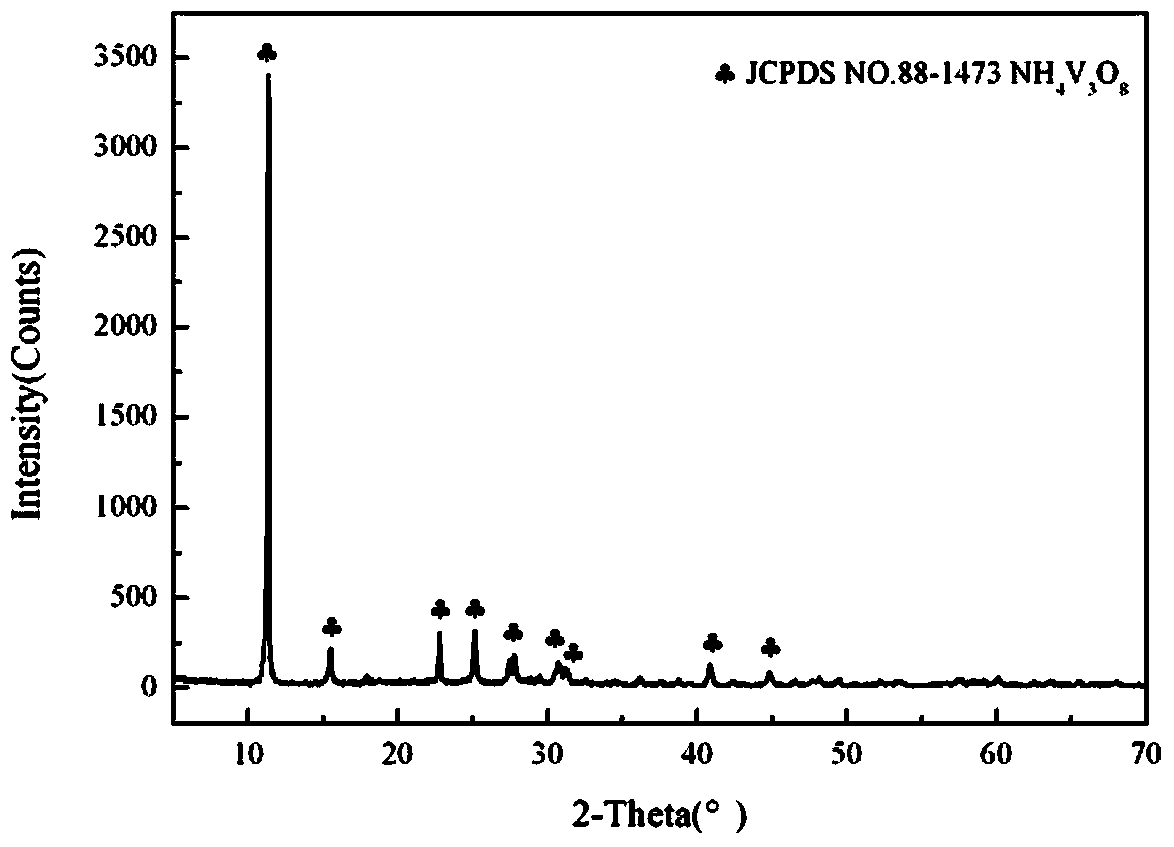

Method for preparing flake-shaped NH4V3O8 microcrystalline with water bath method

A water-bath, flake-like technology is applied in the field of preparing flake NH4V3O8 microcrystals by the water-bath method, which can solve the problems of difficult control of the reaction process, occurrence of side reactions, and high reaction temperature, and achieves uniform morphology, short reaction period, The effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) The analytically pure ammonium metavanadate (NH 4 VO 3 ) was dissolved in deionized water, stirred by magnetic force for 0.5h to dissolve ammonium metavanadate evenly, and prepared into NH 4 + The concentration of 0.05mol / L NH 4 VO 3 Solution, denoted as A solution;

[0026] 2) Use 3mol L ‐1 After adjusting the pH value of the A solution to 3.5 with hydrochloric acid solution, the sonochemical reaction was carried out at an ultrasonic power of 800W for 0.5h to obtain the B solution;

[0027] 3) Pour solution B into a beaker of suitable size, seal the mouth of the beaker, put it into a digital display constant temperature water bath, adjust the water level, and react in a water bath at 70°C for 90 minutes;

[0028] 4) After the reaction in the water bath, cool down to room temperature naturally, centrifuge the obtained suspension to obtain a powder product, then soak the powder product in deionized water and absolute ethanol for 10 minutes respectively, and repe...

Embodiment 2

[0032] 1) The analytically pure ammonium metavanadate (NH 4 VO 3 ) was dissolved in deionized water, stirred by magnetic force for 0.5h to dissolve ammonium metavanadate evenly, and prepared into NH 4 + The concentration is 0.01mol / L of NH 4 VO 3 Solution, denoted as A solution;

[0033] 2) Use 5mol L ‐1 After adjusting the pH value of solution A to 2.0 with a hydrochloric acid solution, a sonochemical reaction was carried out at an ultrasonic power of 400W for 1 hour to obtain solution B;

[0034] 3) Pour the B solution into a beaker of suitable size, seal the mouth of the beaker, put it into a digital constant temperature water bath, adjust the water level, and react in a water bath at 80°C for 60 minutes;

[0035] 4) After the reaction in the water bath, cool down to room temperature naturally, centrifuge the obtained suspension to obtain a powder product, and then soak the product in deionized water and absolute ethanol for 10 minutes respectively, and repeat first w...

Embodiment 3

[0037] 1) The analytically pure ammonium metavanadate (NH 4 VO 3 ) was dissolved in deionized water, stirred by magnetic force for 0.5h to dissolve ammonium metavanadate evenly, and prepared into NH 4 + The concentration is 0.03mol / L of NH 4 VO 3 Solution, denoted as A solution;

[0038] 2) Use 2mol L ‐1 After adjusting the pH value of the A solution to 4.0 with hydrochloric acid solution, the sonochemical reaction was carried out at an ultrasonic power of 600W for 0.5h to obtain the B solution;

[0039] 3) Pour the B solution into a beaker of suitable size, seal the mouth of the beaker, put it into a digital constant temperature water bath, adjust the water level, and react in a water bath at 60°C for 120 minutes;

[0040] 4) After the reaction in the water bath, cool down to room temperature naturally, centrifuge the obtained suspension to obtain a powder product, then soak the powder product in deionized water and absolute ethanol for 10 minutes respectively, and repe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap