Rapid clamping device used for side milling and drilling of carbon fiber thin board

A clamping device and carbon fiber technology, applied in the direction of clamping device, positioning device, clamping, etc., can solve the problems of inability to correctly position the workpiece and cannot guarantee the processing quality, so as to improve production efficiency, reduce alignment time, clamp Even force distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

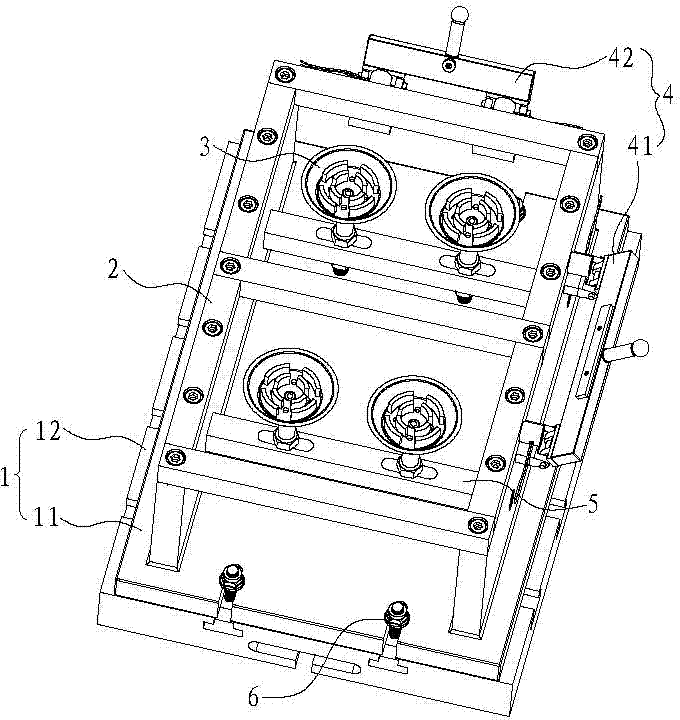

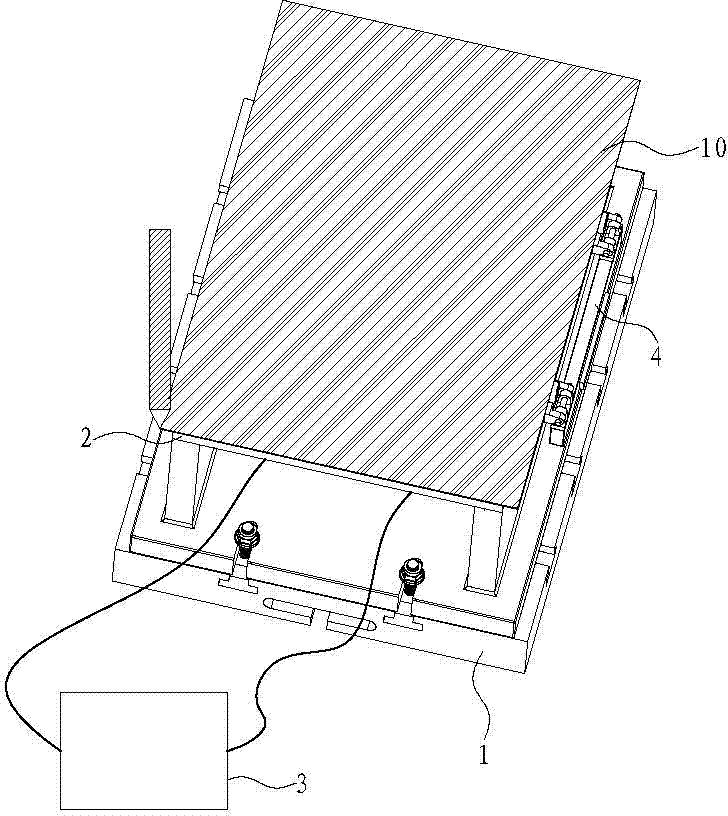

[0026] Such as figure 1 As shown, the present invention is a quick clamping device for side milling and drilling of carbon fiber thin plates. Component 6.

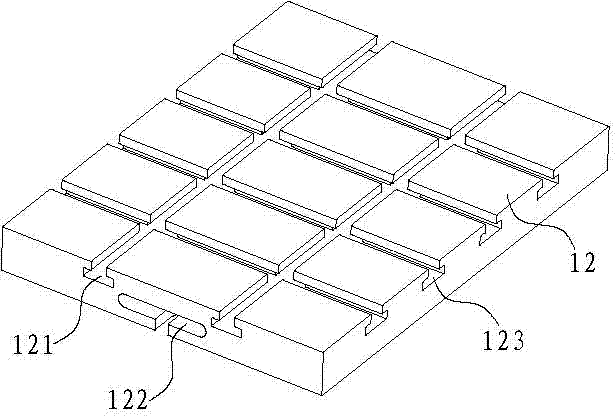

[0027] The clamp body 1 is composed of a clamp body 11 and a clamp body base 12 . to combine image 3 As shown, the clamp body base 12 is provided with front and rear T-shaped grooves 121, U-shaped grooves 122, and left and right T-shaped grooves 123, and the clamp body 1 is fixed on the machine tool workbench by T bolts. The clamp body base 12 is fixed on the machine tool through a T-shaped connecting block, and the fastener assembly 6 fixes the clamp body 11 on the clamp body base 12 . The positioning frame 2 is fixed on the top surface of the clamp body 11 of the clamp body 1 .

[0028] The positioning frame 2 is a rectangular frame.

[0029] The positioning member 4 is composed of left and right magnetic positioning strips 41 and front and rear magnetic positioning blocks 42 . The left and right magnetic positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com