Preparation method of sucrose isomerase

A sucrose isomerase and seed technology, applied in the field of enzyme engineering, can solve the problems of water use, affecting the quality of isomaltulose products, increasing production costs and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

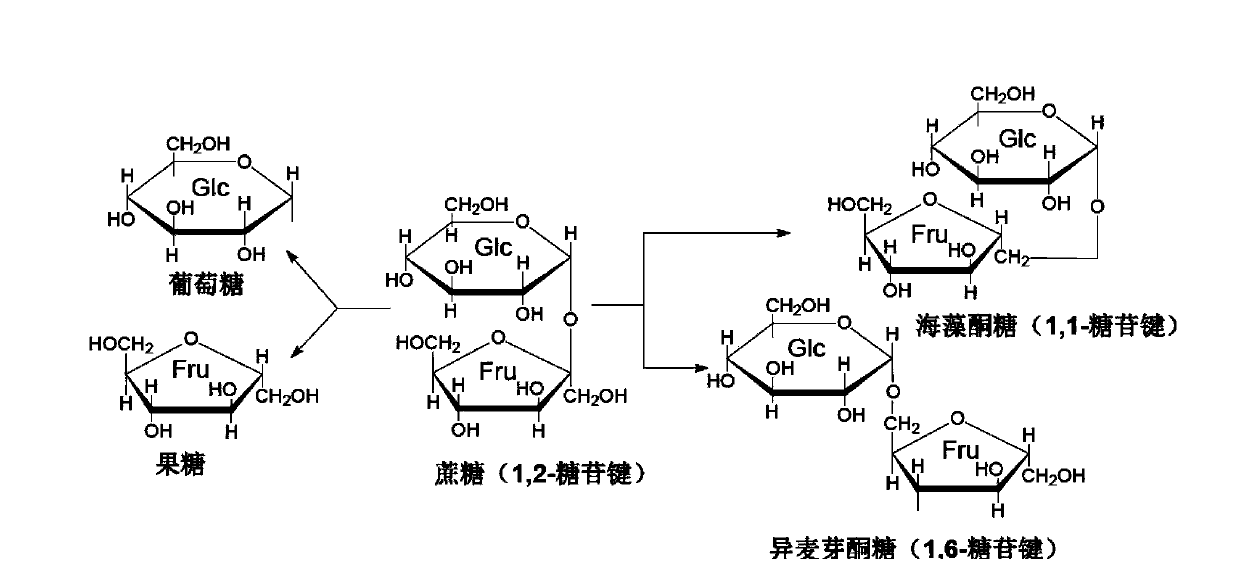

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Pick 1 ring of bacteria from the slant of Klebsiella CCTCC M2013153 stored in the refrigerator at 4°C, inoculate it into a triangular flask containing 25 mL of seed medium, and activate it for 12 hours (30°C, 150 rpm) , according to the inoculum amount of 3%, transferred to the Erlenmeyer flask containing 50mL of fresh seed culture medium, after 4.5 hours of culture in a shaking table at 30°C (150 rpm), inoculate the above seed culture solution according to the inoculum amount of 5%. In a Erlenmeyer flask containing 250 mL of fermentation medium, shake and cultivate for 10 hours at 30° C. in a shaker at 150 rpm. Take the above fermentation broth, centrifuge at 4°C and 10,000g for 25 minutes, wash the cells with deionized water three times, and suspend in 1 / 4 of the original volume of 20mM phosphoric acid-citric acid buffer solution (pH7.0) , ultrasonically crushed in an ice-water bath for 30 minutes, centrifuged at 4°C and 10,000 g for 15 minutes, washed 3 times with wa...

Embodiment 2

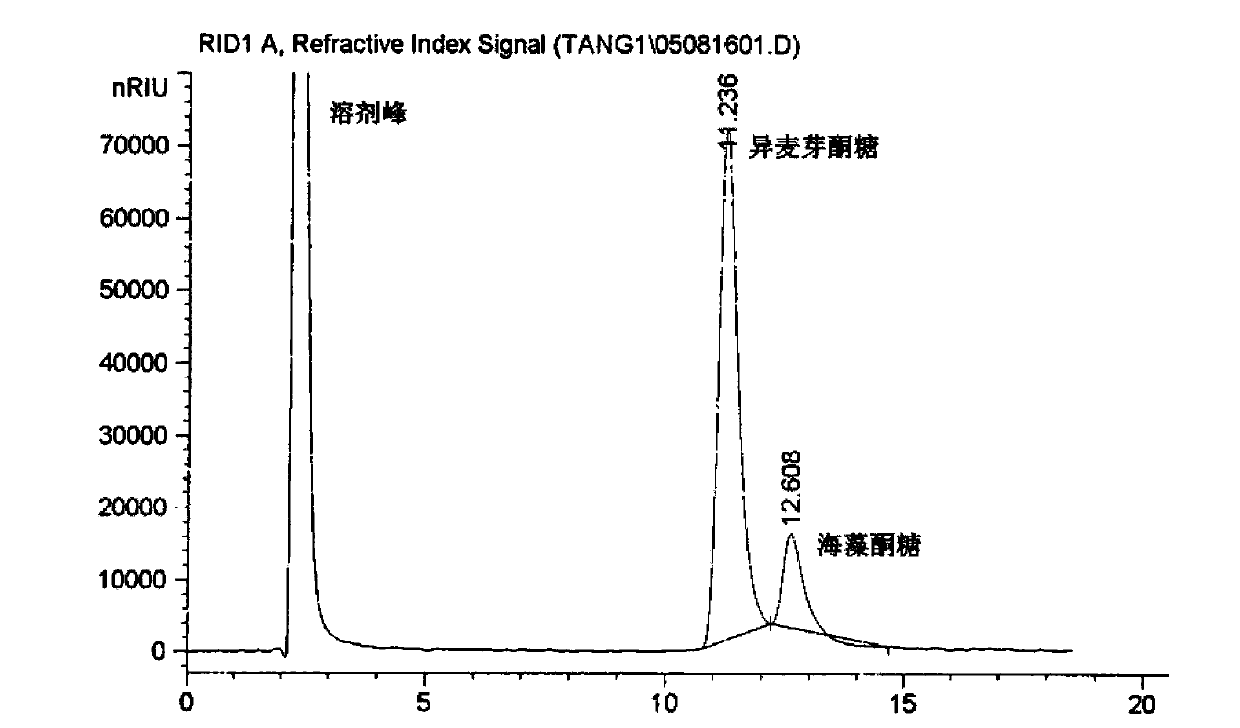

[0036] According to the method described in Example 1, the cell wall fusion sucrose isomerase solution was prepared, and the ratio of the enzyme solution to the sucrose solution was 1:9, the sucrose isomerase was mixed with 20wt% sucrose solution, and placed in a 30°C water bath for 6 hours to convert sucrose to isomaltulose. Confirmation by HPLC analysis ( figure 2 ), the sucrose conversion solution contained 88.39% isomaltulose and 11.61% trehalulose.

[0037] Preparation of 20wt% sucrose solution: Weigh 20g of sucrose, dissolve it in 70mL of 20mM phosphoric acid-citric acid buffer solution (pH7.0), and make up to 100mL.

Embodiment 3

[0039] The non-ultrasonic disrupted cell suspension, cell wall fused sucrose isomerase solution, purified sucrose isomerase solution and GST fused sucrose isomerase solution were mixed with 20 wt% sucrose solution at a ratio of 1:10. After being incubated in a water bath at 30° C. for 6 hours, the reaction was stopped, and the ratios of various sugar components in the sucrose conversion liquid were analyzed by HPLC.

[0040] Table 1 The product composition of sucrose conversion catalyzed by different forms of sucrose isomerase (%)

[0041] Existing form of enzyme

[0042] Compared with the product of cell wall fusion sucrose isomerase, in the conversion product of pure enzyme, the ratio of glucose / fructose is significantly increased, and has no obvious difference from the ratio of other similar enzymes (12.5-13%). When a GST fusion protein was linked to the N-terminus of sucrose isomerase, the glucose / fructose ratio in the sucrose conversion product decreased (8.35%)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com