A sodium-sulfur battery electrolyte thin-walled ceramic tube sintering tool

A sodium-sulfur battery and electrolyte technology, applied in the field of chemical energy storage, to reduce production costs, prevent cracks, and achieve mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

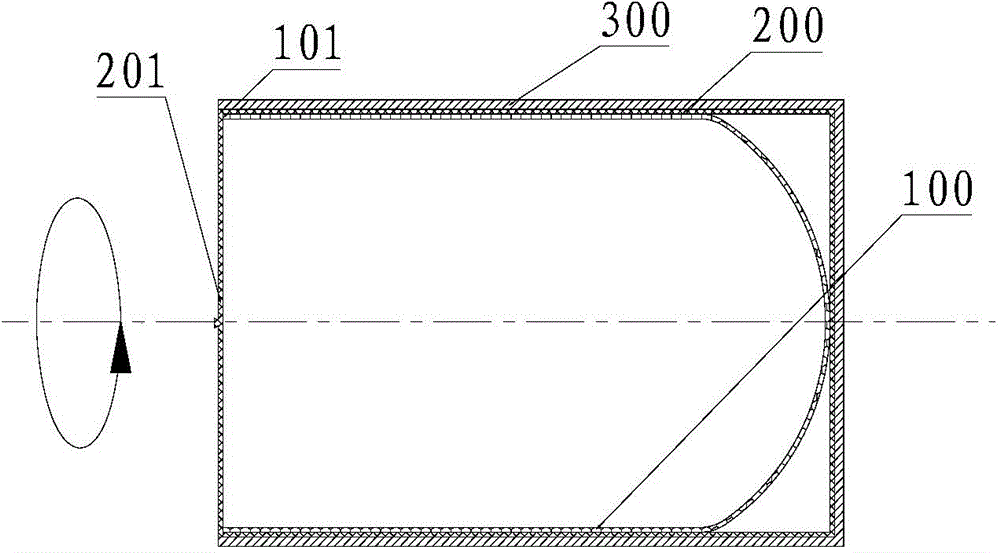

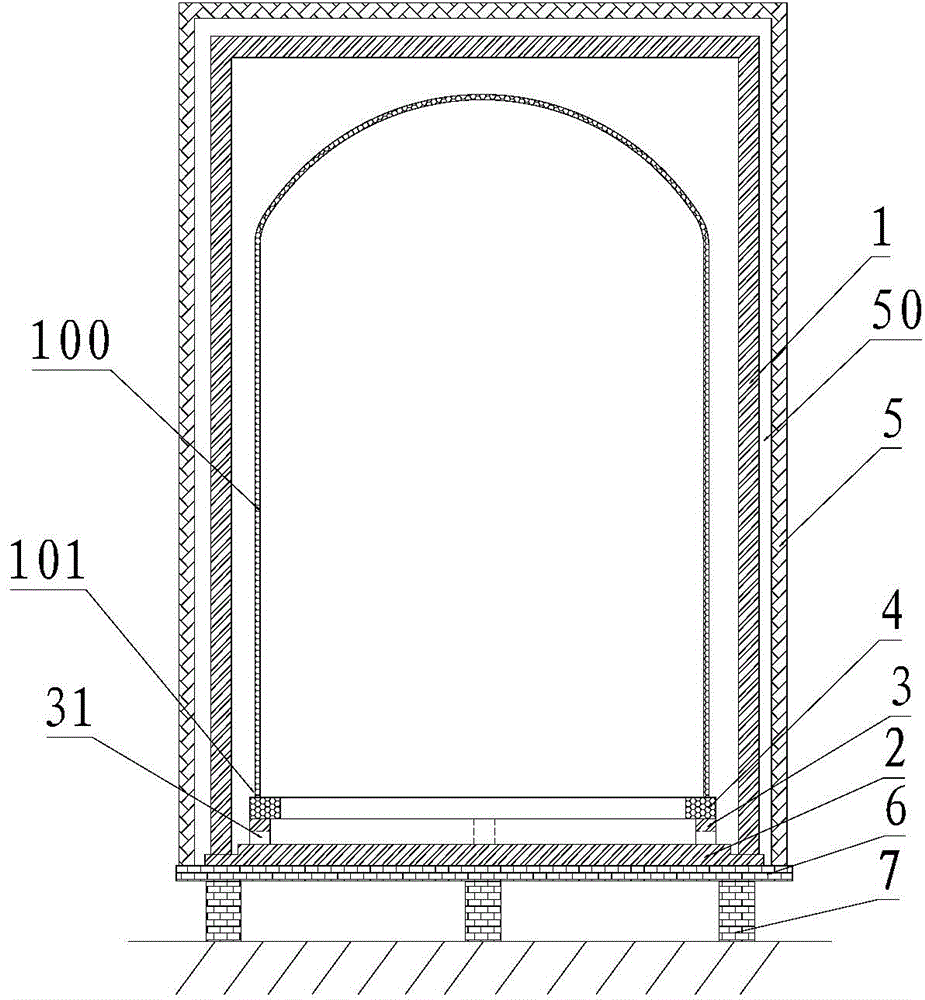

[0016] see figure 2 In order to better understand the technical solution of the present invention, the inventors of the present invention will describe in detail below through specific embodiments in conjunction with the accompanying drawings:

[0017] see figure 2 , a thin-walled ceramic tube sintering tool for a sodium-sulfur battery electrolyte of the present invention, comprising: a container 1, a container base 2, a support ring 3, a synchronous shrinking ring 4, an external container 5 and a kiln car setter 6.

[0018] The container base 2 closes the bottom of the container 1, and the container base 2 is closely matched with the bottom of the container 1 to ensure the "alkaline-enriched" atmosphere in the container 1 during the sintering process.

[0019] The support ring 3 is located on the top surface of the container base 2, and the container base 2 supports the support ring 3. At least one gas exchange channel 31 is opened on the ring wall of the support ring 3 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com