Antistatic decorative board and preparation method thereof

一种装饰板、抗静电的技术,应用在抗静电康倍特板及制备领域,能够解决成本高、达到抗静电级别、体电阻不行等问题,达到粘结力强、使用安全、性能持久的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

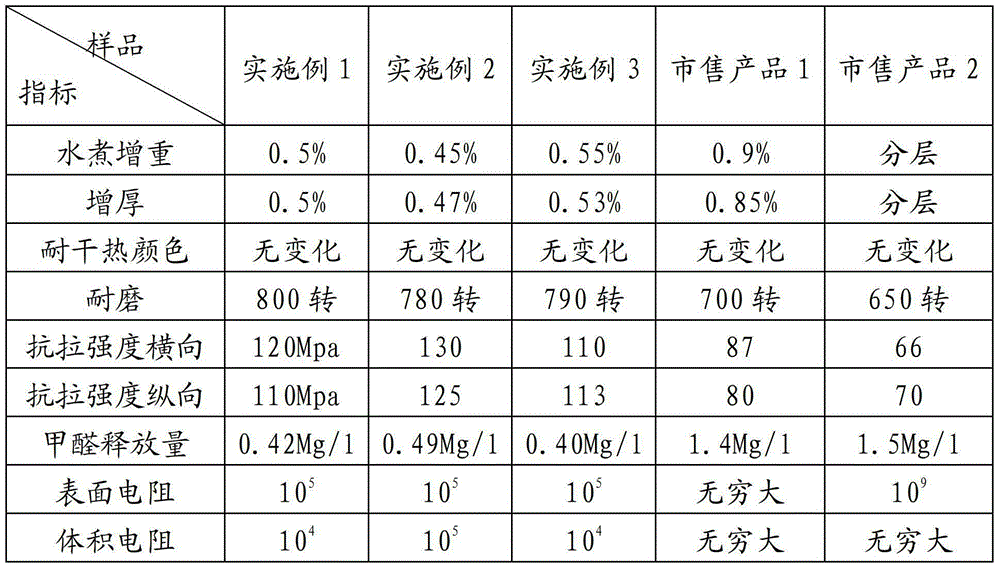

Examples

Embodiment 1

[0026] (1) Weigh the raw materials according to the following weight percentages for later use, 45% of fiber, 40% of phenolic resin, antistatic agent (octadecyl dimethyl hydroxyethyl quaternary ammonium sodium nitrate and sodium phosphate in a weight ratio of 5:5) Mixture) 5%, carbon black 8%, coupling agent (KH-570) 2%; the fiber is made of tree branch as raw material, washed with water and heat-milled, the fiber particle length is 5-10mm, and the width is 0.01-0.3 mm, the diameter of carbon black particles is 0.01~0.1mm;

[0027] (2) Divide the antistatic agent into three parts a, b and c according to the weight ratio of 2:2:6, and add the antistatic agent a and b to the carbon black and the fiber respectively, and then mix the carbon black and the fiber under the action of strong wind Mix them evenly, dry them at 160°C, and set the mixture aside; add the coupling agent and the rest of the antistatic agent to the phenolic resin, mix evenly and heat to 40°C-50°C to make an ad...

Embodiment 2

[0033] (1) Weigh the raw materials according to the following weight percentages for later use, fiber 40%, phenolic resin 45%, antistatic agent (a mixture of sodium sulfide and quaternary ammonium salt (tetrabutylammonium fluoride) in a weight ratio of 5:5) 4% , carbon black 8%, coupling agent (KH-570) 3%; the fibers are made of tree branches as raw materials, washed with water, and made by hot grinding. The length of fiber particles is 5-10mm, and the width is 0.01-0.5mm. Particle diameter is 0.01 ~ 0.3mm;

[0034] (2) Divide the antistatic agent into three parts a, b and c according to the weight ratio of 2:2:6, and add the antistatic agent a and b to the carbon black and the fiber respectively, and then mix the carbon black and the fiber under the action of strong wind Mix them evenly, dry them at 160°C, and set the mixture aside; add the coupling agent and the rest of the antistatic agent to the phenolic resin, mix evenly and heat to 40°C-50°C to make an adhesive, and cool...

Embodiment 3

[0040] (1) Weigh the raw materials according to the following weight percentages for later use: 50% fiber, 35% phenolic resin, antistatic agent (a mixture of dioctyl sulfonate calcium succinate-603 and sodium sulfate in a weight ratio of 5:5) ) 8%, carbon black 5.5%, coupling agent (KH-570) 1.5%; the fibers are made of tree branches as raw materials, washed with water, and made by hot grinding. The length of fiber particles is 5-10mm, and the width is 0.01-0.5mm , the carbon black particle diameter is 0.01-0.3mm;

[0041] (2) Divide the antistatic agent into three parts a, b and c according to the weight ratio of 2:2:6, and add the antistatic agent a and b to the carbon black and the fiber respectively, and then mix the carbon black and the fiber under the action of strong wind Mix them evenly, dry them at 160°C, and use the mixture for later use; add the coupling agent and the rest of the antistatic agent to the phenolic resin, mix evenly and heat to 45°C-50°C to make an adhe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| internal resistance | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com