A kind of preparation method of chlorophyll copper acid and copper sodium salt

A technology of chlorophyll cupric acid and copper sodium salt, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of many recovery and storage equipment, time, and large amount of organic reagents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

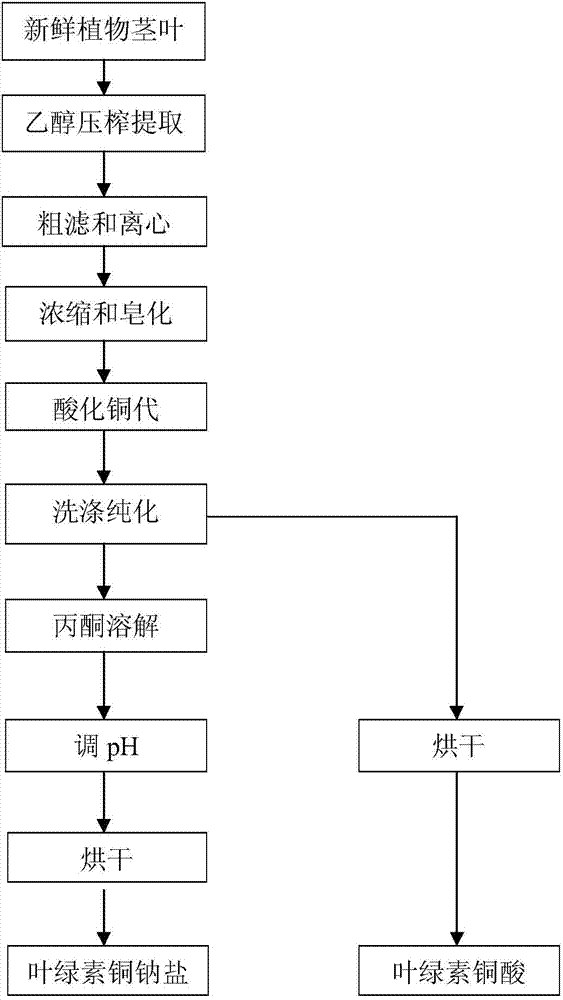

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of chlorophyll cupric acid and copper sodium salt from fresh Rumex.

[0029] Weigh 10kg fresh Rumex stems and leaves, add 20g CaCO 3 , add 40L of 90% ethanol solution, beating, and the extraction temperature is controlled at 50°C. Squeeze the slurry with a belt press, collect 47.5L of juice, and remove waste residue. After the juice is roughly filtered with a 180-mesh filter cloth, it is centrifuged at a high speed at a speed of 4000 rpm to remove waste residue. Adjust the pH to 11 with 5% NaOH solution, control the temperature at 45° C. and concentrate under reduced pressure while performing saponification to obtain 11.5 L of concentrated saponified liquid. The saponified solution was adjusted to pH 2 with hydrochloric acid, and 10% CuSO was added 4 The solution was 230ml, and the temperature was controlled at 75°C for 1.0h. After filtration under reduced pressure, the precipitate was washed three times with deionized water at a temperature of...

Embodiment 2

[0030] Example 2 Preparation of chlorophyll cupric acid and copper sodium salt from fresh spinach.

[0031] Weigh 10kg fresh spinach stems and leaves, add 40g CaCO 3 , add 60L of 95% ethanol solution, make a slurry, and control the extraction temperature at 55°C. The slurry is squeezed by a belt press, and 67L of juice is collected to remove waste residue. After the juice is coarsely filtered with a 250-mesh filter cloth, it is centrifuged at a high speed at a speed of 6000 rpm to remove waste residue. Adjust the pH to 12 with 5% NaOH solution, control the temperature at 50° C. and concentrate under reduced pressure while performing saponification to obtain 13.3 L of concentrated saponified liquid. The saponified solution was adjusted to pH 2.7 with hydrochloric acid, and 10% CuSO was added 4 The solution was 300ml, and the temperature was controlled at 70°C for 1.5h. After filtration under reduced pressure, the precipitate was washed three times with deionized water at a ...

Embodiment 3

[0032] Example 3 Preparation of chlorophyll cupric acid and copper sodium salt from fresh spinach.

[0033] Weigh 10kg fresh spinach stems and leaves, add 50g CaCO 3 , add 50L of 95% ethanol solution, make a slurry, and control the extraction temperature at 60°C. Squeeze the slurry with a belt press, collect 55L of juice, and remove waste residue. After the juice is coarsely filtered with a 300-mesh filter cloth, it is centrifuged at a high speed at a speed of 5000 rpm to remove waste residue. Adjust the pH to 12 with 5% NaOH solution, control the temperature at 60° C. and concentrate under reduced pressure while performing saponification to obtain 12 L of concentrated saponified liquid. The saponified solution was adjusted to pH 3 with hydrochloric acid, and 10% CuSO was added 4 The solution was 400ml, and the temperature was controlled at 60°C for 1.5h. After filtration under reduced pressure, the precipitate was washed three times with deionized water at a temperature o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com