Epoxy-modified polyester acrylate and preparation method thereof

A technology of polyester acrylate and acrylate, which is applied in the field of polyester acrylate, can solve the problems of long preparation time, poor adhesion, slow curing speed, etc., and achieve extremely low curing shrinkage, excellent adhesion and flexibility, The effect of superior comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

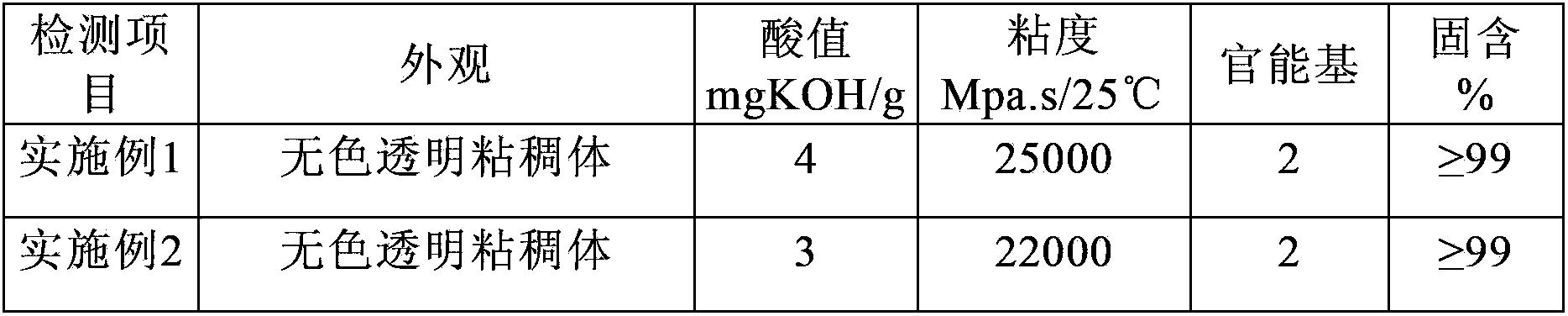

Examples

Embodiment 1

[0026] Preparation of UV-cured epoxy-modified polyester acrylate resin:

[0027] 1) Add 60 parts by weight of epoxy resin with a molecular weight of 600 and 30 parts by weight of phthalic anhydride into the reactor, and react at 100°C for 3 hours;

[0028] 2) Add 20 parts by weight of acrylic acid to the reactor, and react at 105°C for 2 hours;

[0029] 3) Add 0.5 parts by weight of triethylamine to the reacted product in step 2), then add 0.8 parts by weight of 2,6-di-tert-butyl-p-cresol under nitrogen protection, and react at a temperature of 111°C for 2 hours ;

[0030] 4) Add 0.1 parts by weight of nitrobenzene to the reacted product in step 3), react at a temperature of 110°C for 2 hours, then add 10 parts by weight of hydroxypropyl acrylate to react for 1 hour, stir and vacuumize to obtain the product.

Embodiment 2

[0032] Preparation of UV-cured epoxy-modified polyester acrylate resin:

[0033] 1) Add 50 parts by weight of epoxy resin with a molecular weight of 600 and 20 parts by weight of phthalic anhydride into the reactor, and react at 105°C for 2 hours;

[0034] 2) Add 40 parts by weight of acrylic acid to the reactor, and react at 108°C for 1.5 hours;

[0035] 3) Add 0.7 parts by weight of triethylamine to the reacted product in step 2), then add 1.2 parts by weight of 2.6-di-tert-butyl-p-cresol under nitrogen protection, and react at a temperature of 112°C for 1.5 hours;

[0036] 4) Add 0.5 parts by weight of nitrobenzene to the reacted product in step 3), react at a temperature of 112°C for 2 hours, then add 30 parts by weight of hydroxypropyl acrylate to react for 1 hour, stir and vacuumize to obtain the product.

Embodiment 3

[0038] Preparation of UV-cured epoxy-modified polyester acrylate resin:

[0039] 1) Add 40 parts by weight of epoxy resin with a molecular weight of 600 and 10 parts by weight of phthalic anhydride into the reactor, and react at 103°C for 2.5 hours;

[0040] 2) Add 20 parts by weight of acrylic acid to the reactor, and react at 110°C for 2 hours;

[0041] 3) Add 1 part by weight of triethylamine to the reacted product in step 2), then add 1.5 parts by weight of 2,6-di-tert-butyl-p-cresol under nitrogen protection, and react at a temperature of 110°C for 2 hours ;

[0042] 4) Add 0.3 parts by weight of nitrobenzene to the reacted product in step 3), react at a temperature of 115°C for 1.5 hours, then add 20 parts by weight of hydroxypropyl acrylate to react for 1 hour, stir and mix and vacuumize to obtain the product .

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com