Preparation method of polylactic acid particles

A technology of polylactic acid microparticles and polylactic acid, which is applied in the field of polymer microparticle preparation, can solve the problems of difficult scale-up of pilot scale, complicated preparation process, and numerous influencing factors, and achieve the effect of low equipment requirements, simple operation process and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

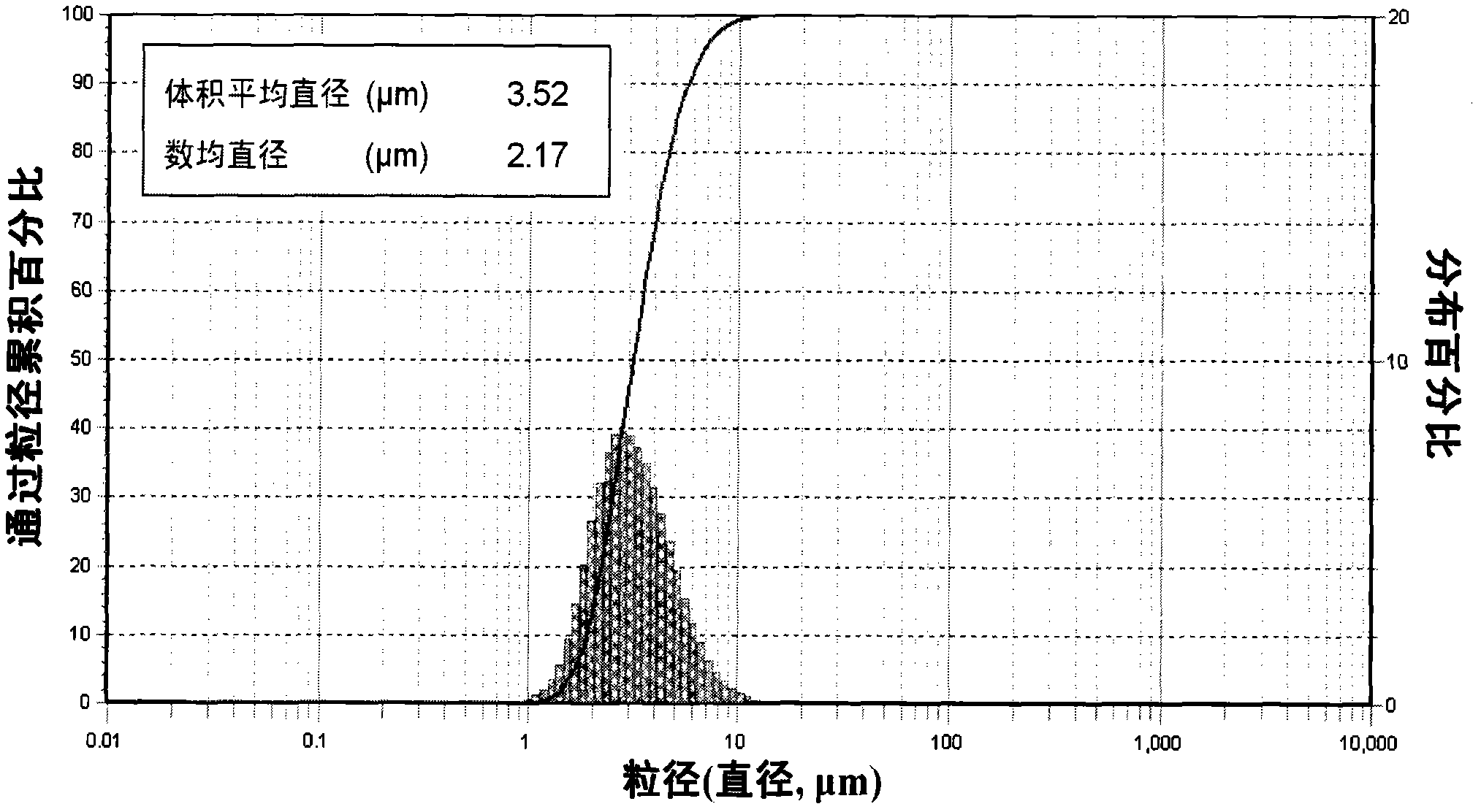

Embodiment 1

[0039] In a three-necked flask of 500ml, add 6.0g polylactic acid (D lactic acid mass content 4.25%, model is Ingeo TM Biopolymer 4043D), 5.0g polyvinylpyrrolidone, 92g diethylene glycol dimethyl ether, heated to 140°C, and stirred at a speed of 450rpm until the polymer was dissolved. The temperature of the system was lowered to 60° C., and then 100 g of deionized water was added dropwise to the above system at a rate of 1.67 g / min. After the dropwise addition, the resulting suspension was filtered, washed with 200 g of deionized water, filtered, and the filtrate was vacuum-dried at 45° C. for 12 hours to obtain 2.8 g of white polylactic acid powder with a volume average diameter of 3.5 μm, the particle size distribution index is 1.6, and the oil absorption is 90mL / 100g.

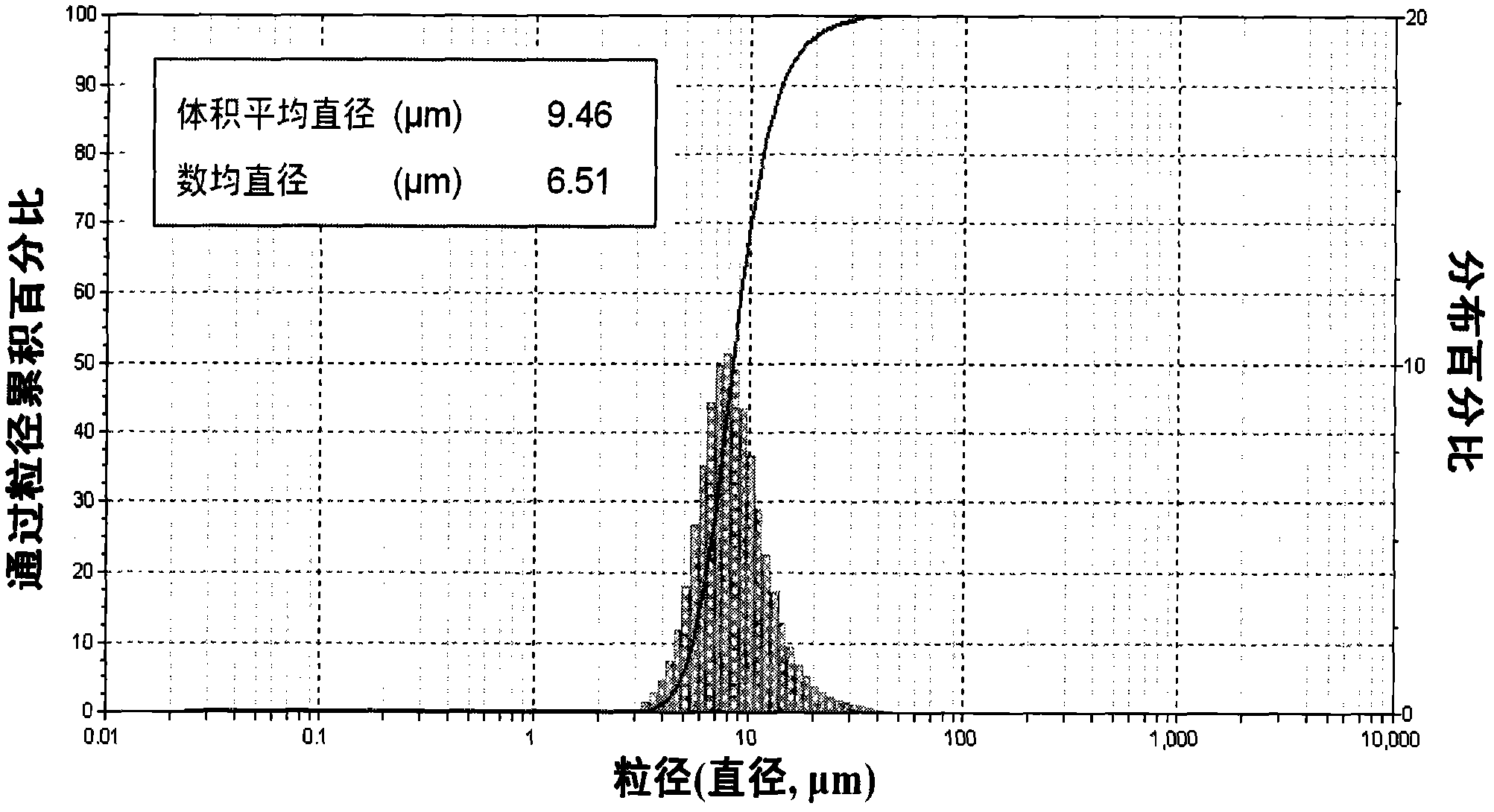

Embodiment 2

[0041] In a three-necked flask of 500ml, add 3.0g polylactic acid (D lactic acid mass content 4.25%, model is Ingeo TMBiopolymer 4043D), 5.0g polyvinyl alcohol (model PVA-GL-05), 92g diethylene glycol dimethyl ether, heated to 110°C, and stirred at a speed of 450rpm until the polymer was dissolved. The temperature of the system was lowered to 55° C., and then 100 g of methanol was added dropwise to the above system at a rate of 1.67 g / min. After the dropwise addition, the resulting suspension was filtered, washed with 200 g of deionized water, filtered, and the filtrate was vacuum-dried at 45° C. for 12 hours to obtain 2.7 g of white polylactic acid powder with a volume average diameter of 31.5 μm, the particle size distribution index is 1.7, and the oil absorption is 420mL / 100g.

Embodiment 3

[0043] In a three-necked flask of 500ml, add 5.0g polylactic acid (D lactic acid mass content 1.40%, model is Ingeo TM Biopolymer 6251D), 5.0g polyvinyl alcohol (model PVA-GL-05), 92g N,N-dimethylformamide, heated to 80°C, and stirred at a speed of 450rpm until the polymer was dissolved. The temperature of the system was lowered to 55° C., and then 100 g of methanol was added dropwise to the above system at a rate of 1.67 g / min. After the dropwise addition, the resulting suspension was filtered, washed with 200 g of deionized water, filtered, and the filtrate was vacuum-dried at 45° C. for 12 hours to obtain 2.7 g of white polylactic acid powder with a volume average diameter of 15.8 μm, the particle size distribution index is 1.8, and the oil absorption is 370mL / 100g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| oil absorption | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com