High cellulase yield strain and method for producing neutral cellulase through fermentation

A neutral cellulase and cellulase technology, applied in the biological field, can solve the problems of high cost, small scale, and no wild strains with high enzyme-producing activity or genetically modified engineering bacteria technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

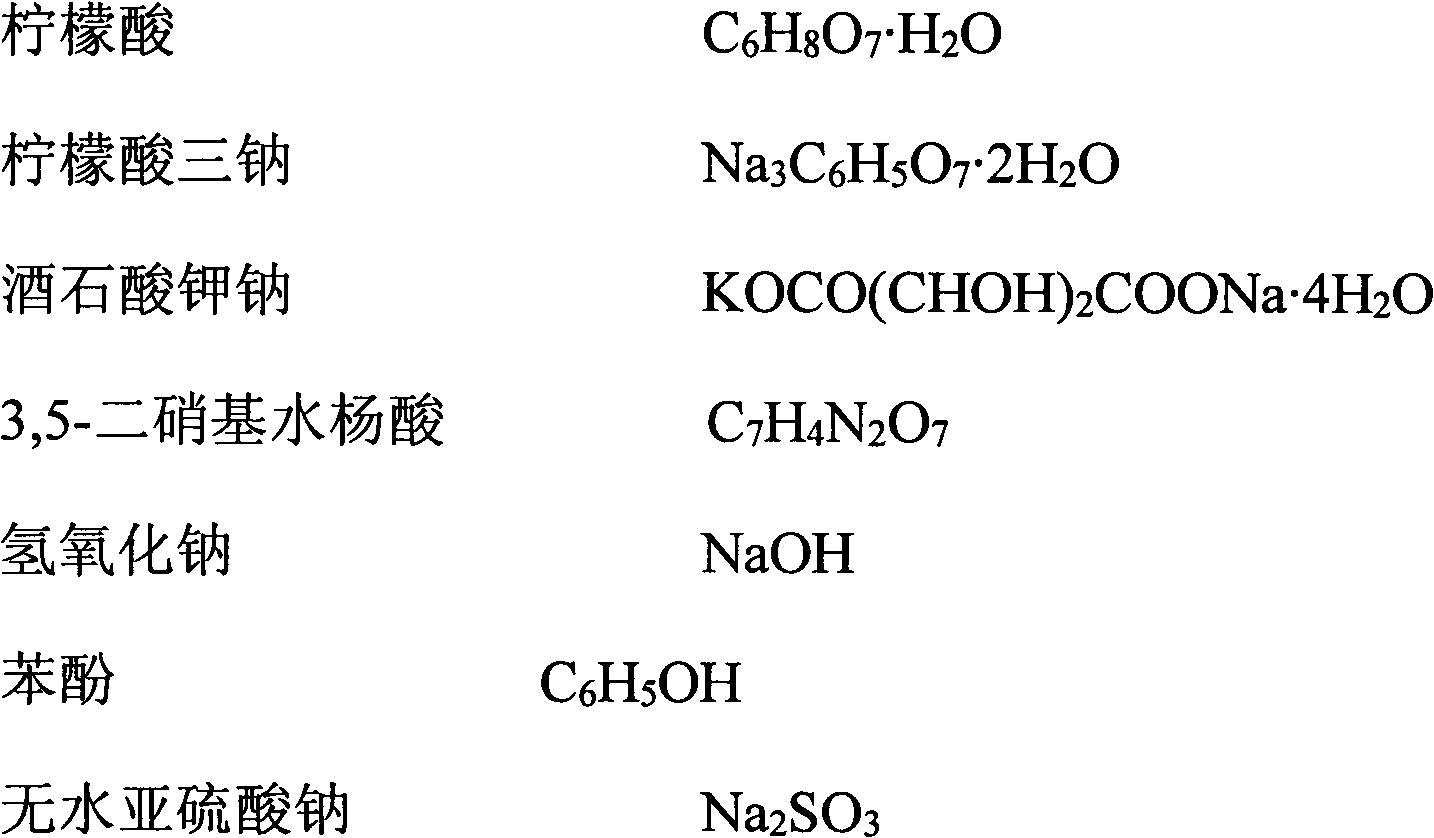

Method used

Image

Examples

Embodiment 1

[0072] Take a ring of slant strains and spot mycelium on a PDA plate, culture at 30°C for 7 days, take a plate and wash it with 10ml of sterile water, break it into a uniform spore suspension, take 1ml of the spore suspension and insert it into a Prepare several parts in a 250ml Erlenmeyer flask of 50ml seed culture medium. Culture conditions: rotation speed 200rpm, temperature 30 degrees, constant temperature culture for 3 days, which is fermented seed liquid.

[0073] Put 5L of enzyme-producing medium in a 7L fermenter, add 2.5ml of defoamer, and sterilize at 121°C for 30 minutes. After cooling, add 500ml of the above-mentioned fermented seed liquid according to 10% inoculum. The culture conditions are: speed 200r / min, temperature 30°C, ventilation rate 1.2L / min / L, after 150 hours of fermentation time, extract the crude enzyme liquid, and measure the enzyme activity according to the enzyme activity method, the enzyme activity of the fermentation liquid reaches 5080IU / L.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com