Surface acoustic wave (SAW) formaldehyde gas sensor using water to absorb formaldehyde

A surface acoustic wave, formaldehyde gas technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze fluids, etc., can solve the problem that the performance of the surface acoustic wave formaldehyde sensor cannot meet the actual needs, and achieve the effect of small molecular mass and high detection sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

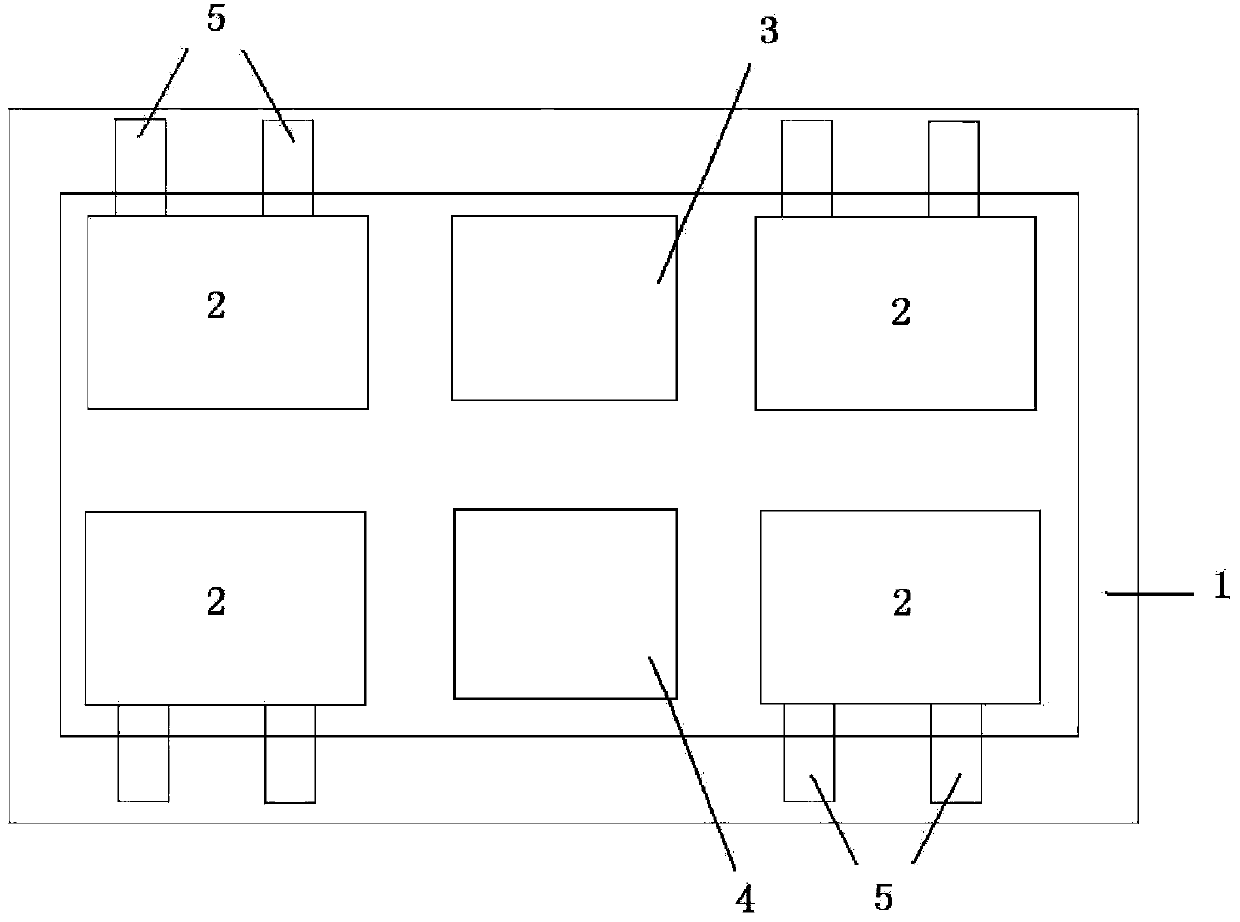

[0030] The piezoelectric substrate 1 chooses ST-quartz, the electrode 2 chooses aluminum, the conductive particle material of the conductive sensitive film 3 chooses carbon nanotubes, and the material for absorbing water vapor is the same as that of the insulating sensitive film 4, and chooses dodecyl alcohol.

[0031] The preparation method of surface acoustic wave formaldehyde gas sensor provided by the present invention is as follows:

[0032]A layer of aluminum film with a thickness of about 0.55 μm is prepared on the front surface of the piezoelectric substrate 1 by vacuum thermal evaporation process. Then use the spin coating process to deposit a layer of photoresist on the surface of the aluminum film. After pre-baking at 100°C for 1 minute, cover the surface with a photoresist, expose for 10 seconds, remove the photoresist, and develop at 25°C N(CH3)4OH Soaked in the solution for 5 seconds, the exposed photoresist dissolves, exposing the aluminum film, and the covered ...

Embodiment 2

[0034] Lithium niobate is selected for the piezoelectric substrate 1, gold / titanium is selected for the electrode 2, and titanium is used as an intermediate layer between the substrate and the gold film to improve the adhesion of the gold film, and carbon black is selected for the conductive particle material of the conductive sensitive film 3 , The material for absorbing water vapor is the same as the insulating sensitive film 4, and polyvinyl acetate is selected.

[0035] Preparation of interdigitated electrodes by stripping process: Spin-coat a layer of photoresist, and after pre-baking at 100°C for 1 minute, cover a photoresist plate on the surface, expose for 10 seconds, remove the photoresist plate, and heat at 25°C in N(CH3)4OH After soaking in the developing solution for 5 seconds, the exposed photoresist dissolves, exposing the piezoelectric substrate (1), and the covered photoresist remains. After rinsing with deionized water, bake at 180°C for 20 minutes; use the ma...

Embodiment 3

[0037] The piezoelectric substrate 1 is lithium niobate, the electrode 2 is aluminum, the conductive particle material of the conductive sensitive film 3 is gold nanoparticles, and the material for absorbing water vapor is the same as that of the insulating sensitive film 4, and polysiloxane is selected.

[0038] A layer of aluminum film with a thickness of about 0.55 μm is prepared on the front surface of the piezoelectric substrate 1 by vacuum thermal evaporation process. A layer of photoresist is deposited on the surface of the aluminum film by spin-coating process. After pre-baking at 100° C. for 1 minute, a photoresist plate is covered on the surface, and the photoresist plate is removed after exposure for 10 seconds. 3 ) 4 Soak in OH developer for 5 seconds, the exposed photoresist dissolves, exposing the aluminum film, and the covered photoresist remains. After rinsing and baking at 180° C. for 20 minutes, the aluminum film in the area not covered by the photoresist is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com