Preparation method of ternary anode material of lithium ion battery

A lithium-ion battery, cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of fast decay rate and high specific capacity, and achieve the effects of stable performance, stable electrochemical performance and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

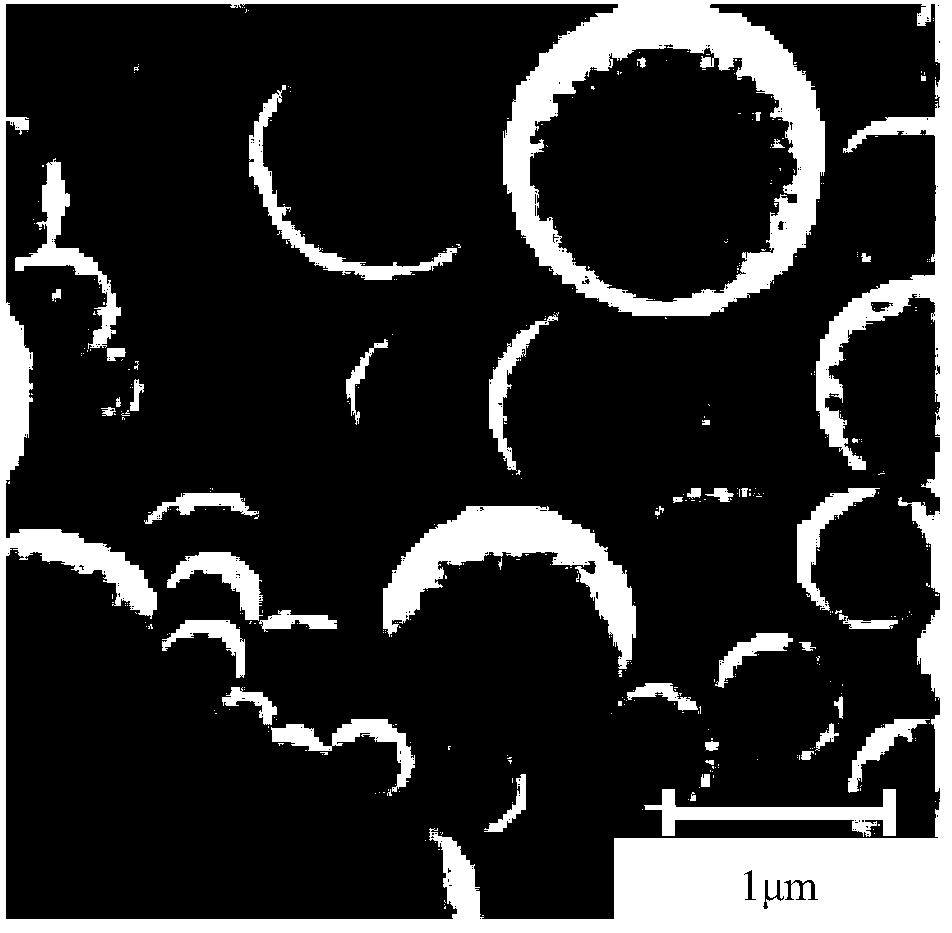

Image

Examples

Embodiment 1

[0028] To obtain 100g (1.1mol) LiNi 0.3 co 0.3 mn 0.3 o 2 Taking the positive electrode material as an example, the required raw materials are 82.12g (0.33mol) of analytically pure nickel oxalate, 82.20g (0.33mol) of cobalt oxalate, 80.88g (0.33mol) of manganese oxalate, and 46.17g (1.1mol) of lithium hydroxide hydrate.

[0029] Mix the raw materials, add 500g of anhydrous alcohol, put them into a ball mill (ball mill model: BXQM2L, Nanjing Telun New Instrument Co., Ltd.) and mix for 2 hours, and put the mixed and milled wet material in a vacuum of 0.01MPa at a temperature of 100°C Dry for 12 hours to obtain a mixed reaction powder for subsequent use. Put the reaction powder into the feeder of the plasma spraying equipment with a screw feeder at a speed of 1g / s, and then scrape the powder into the high-temperature (temperature 3500°C) plasma melting chamber with a voltage of 10,000 V. The plasma gas is pure oxygen. Utilize the high-temperature instant heating of high-temp...

Embodiment 2

[0033] To obtain 50g (0.55mol) LiNi 0.5 co 0.2 mn 0.3 o 2 Taking the positive electrode material as an example, the required raw materials are composed of 68.44g (0.275mol) of analytically pure nickel oxalate, 27.4g (0.11mol) of cobalt oxalate, 40.44g (0.165mol) of manganese oxalate, and 20.08g (0.55mol) of hydrated lithium hydroxide raw materials.

[0034] Mix the raw materials, then add 200g of absolute alcohol, put it into a ball mill and mix for 6 hours, dry the mixed and ground wet material in a vacuum of 0.01MPa, at 110°C for 12 hours, and get the mixed reaction powder for later use . Put the reaction powder into the feeder of the plasma spraying equipment, and then scrape the powder into the high-temperature plasma melting chamber after adding voltage (cavity gas: 50% oxygen plus 50% air), using 50,000 V high temperature The high-temperature instant heating of air plasma, the feeding speed is 100g / s, the reaction powder reacts immediately, and LiNi is formed rapidl...

Embodiment 3

[0037] To obtain 100g (1.1mol) LiNi 0.5 co 0.2 mn 0.3 o 2 Taking the positive electrode material as an example, the required raw materials are composed of 136.87g (0.55mol) of analytically pure nickel oxalate, 54.80g (0.22mol) of cobalt oxalate, 80.88g (0.33mol) of manganese oxalate, and 46.17g (1.1mol) of hydrated lithium hydroxide raw materials.

[0038] Mix the raw materials, add 1000g of absolute alcohol, put it into a ball mill and mix for 8 hours, dry the mixed and ground wet material in a vacuum of 0.01MPa, at 120°C for 6 hours, and get the mixed reaction powder for later use. The reaction powder is put into the feeder of the plasma spraying equipment, and then the powder is scraped into the high-temperature plasma melting chamber after the voltage is added, and the high-temperature gas plasma of 40,000 V high-temperature air plasma (50% oxygen plus 50% air) high temperature instantaneous heating, the reaction powder reacts immediately and quickly forms LiNi 0.5 co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com