Flat tube type solid oxide fuel cell pack

A technology of solid oxide and fuel cell stacks, which is applied in the direction of solid electrolyte fuel cells, fuel cell groups, fuel cells, etc. It can solve the problems of large airflow resistance, gas utilization rate and battery performance degradation, and achieve easy assembly and compact structure , The effect of high current collection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

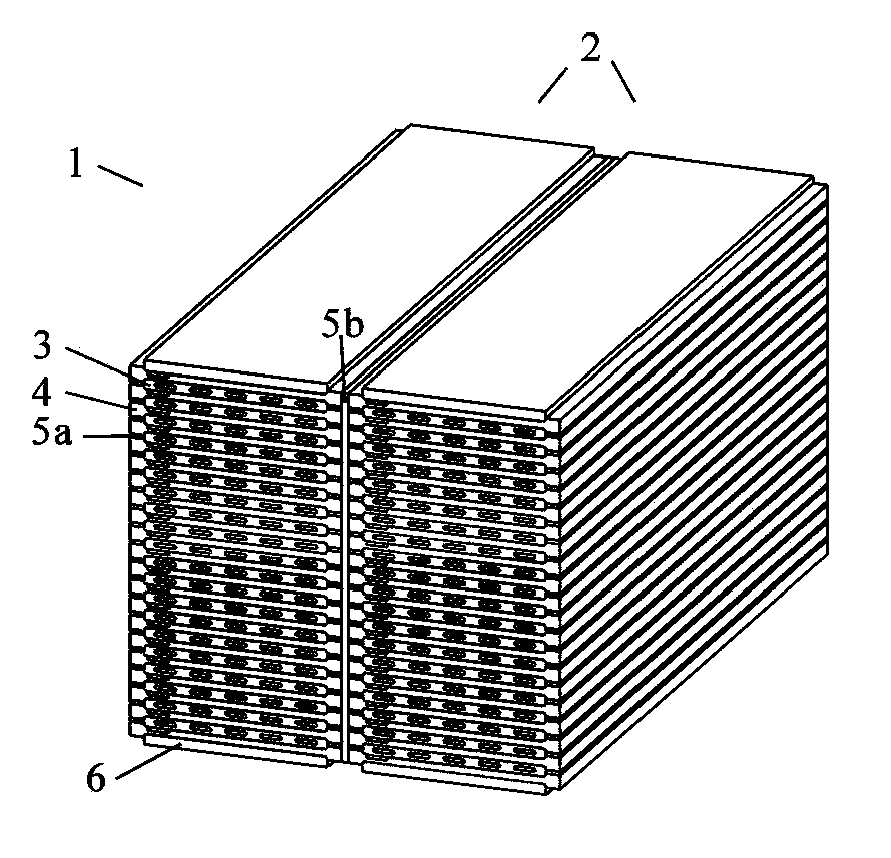

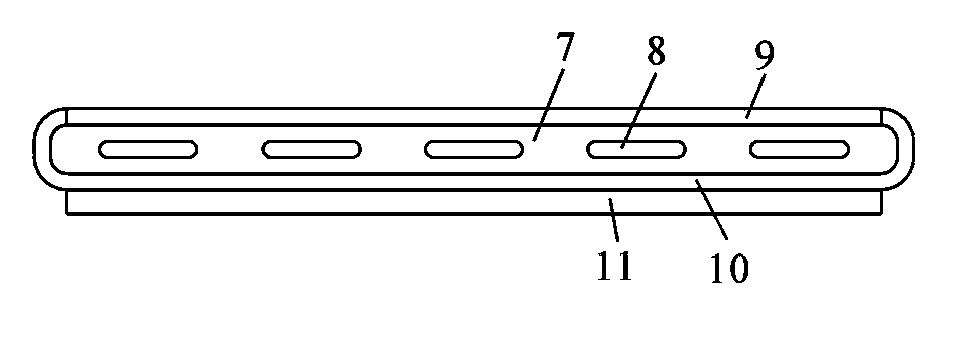

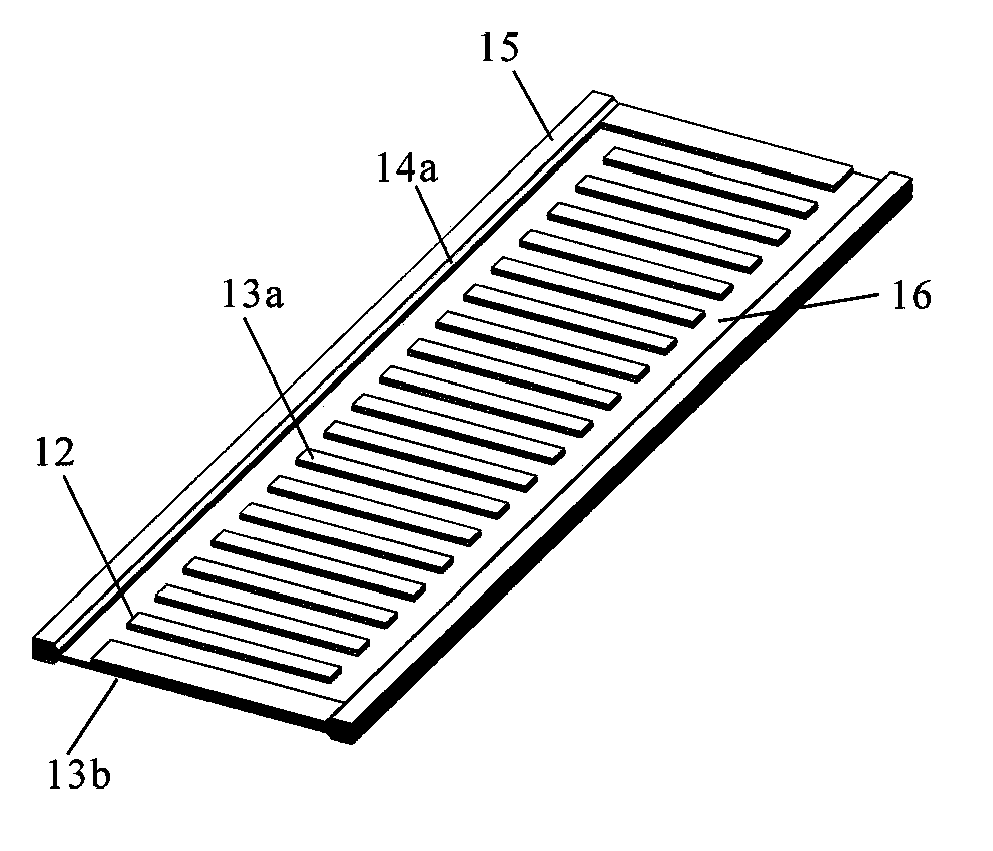

[0029] figure 1 It is a perspective view showing an embodiment of a flat-tube SOFC stack. figure 2 is a schematic diagram of the fuel cell unit structure, image 3 yes figure 1 Schematic diagram of the connected components in the middle cell stack.

[0030] Such as figure 1 As shown, the flat tube SOFC battery stack 1 in this embodiment is composed of two battery packs 2 placed side by side. Each battery pack includes a plurality of alternately placed fuel cell units 3 , connecting parts 4 and insulating materials 5 a between the connecting parts. Collector end plates 6 are arranged at both ends of the battery pack, and current is drawn through the collector end plates for use by external loads. According to the requirements of the load, the battery packs can be connected in series or in parallel (not shown in the figure). In order to prevent a short circuit between the battery packs, an insulating material 5b is provided between the two battery packs. Insulating mater...

Embodiment 2

[0040] Such as Figure 6 As shown, the difference from Embodiment 1 is that on the plate-shaped alloy connection part 4 constituting the flat tube type SOFC battery pack 2, a plurality of short rectangular bosses 12 are set, and between the plurality of short rectangular bosses Formed cross-distributed longitudinal and transverse gas flow channels, making the flow field distribution more uniform.

Embodiment 3

[0042] Such as Figure 7 As shown, the difference from Example 1 is that a plurality of V-shaped bosses 12 are arranged on the plate-shaped alloy connection part 4 constituting the flat-tube SOFC battery pack 2, which can effectively disturb the flow field of the air. And the formation of turbulent flow is conducive to increasing the concentration of reaction gas on the surface of the external electrode and enhancing mass transfer. In addition, in this embodiment, the supporting electrode 7 is a cathode, the external electrode 9 is an anode, and the insulating material 5a uses a glass-ceramic sealing material to obtain the required airtightness. In this embodiment, the plate-shaped alloy substrate 1 uses a Ni-Cr alloy with a brand name of Inconel625, without pre-oxidation and coating treatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com