Method for building desulfurization exhaust chimney based on three-dimensional (3D) printing and borosilicate glass

A borosilicate glass, 3D printing technology, applied in glass molding, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of desulfurization and exhaust chimneys that have not yet been found, and achieve strong resistance to sulfuric acid erosion and high temperature resistance Good, small thermal expansion coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

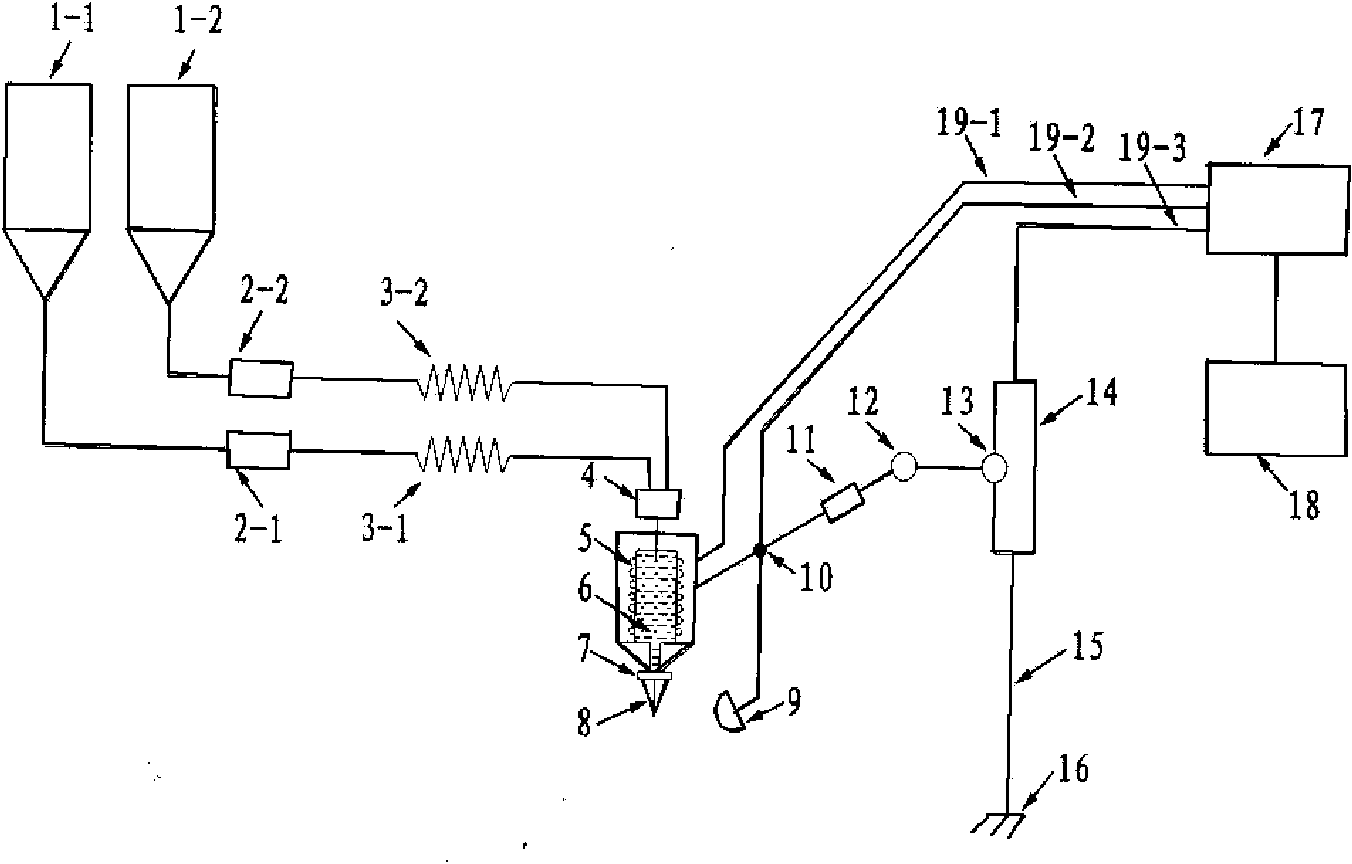

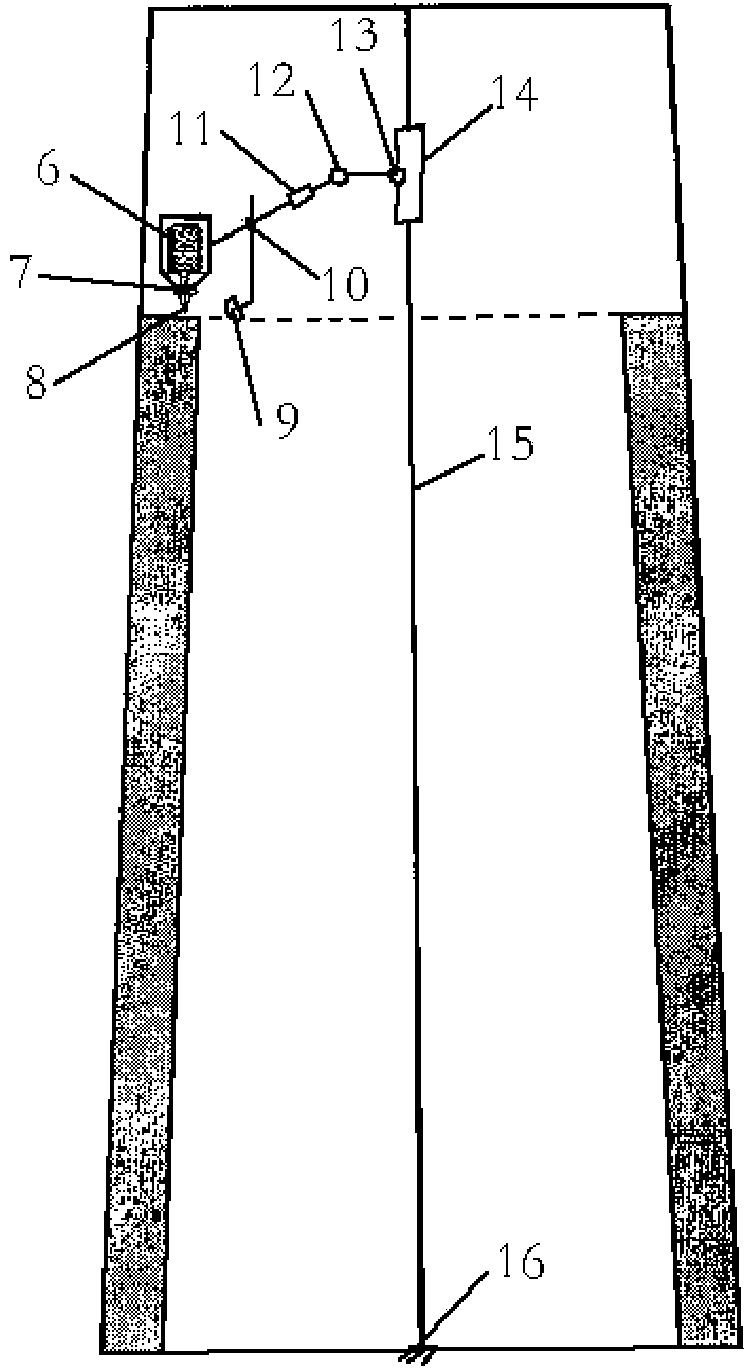

[0029] The invention provides a method for constructing a desulfurization exhaust chimney based on 3D printing and borosilicate glass. Using silicon carbide fiber reinforced borosilicate glass as a building material, 3D printing technology is used as a molding method to prepare a desulfurization exhaust chimney; the specific implementation is described as follows:

[0030] (1) First, calculate the size of the chimney according to the smoke exhaust function requirements of the chimney and the mechanical properties of silicon carbide reinforced borosilicate glass, based on the chimney construction site and the calculated dimensions of the chimney internal diameter and chimney thickness, in the computer Generate a digital 3D model of the chimney. The 3D model takes the center point of the vertical projection of the chimney on the ground as the origin, and uses the Cartesian three-dimensional coordinate axis to establish a series of discrete three-dimensional data. The three-dimens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com