A method for manufacturing an epoxy compound and an epoxy compound

A technology of epoxy compound and manufacturing method, applied in the direction of organic chemistry, etc., can solve the problems of residual, unsuitable for removing quaternary salt compounds, difficult to adsorb quaternary salt compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the present invention is characterized by comprising the following step 1, step 2 and step 3.

[0030] Step 1: After the olefin compound is oxidized in a mixed liquid composed of olefin compound, hydrogen peroxide solution, quaternary salt compound, heteropolyacid and organic solvent, the step of obtaining an organic solution (A) containing an epoxy compound ;

[0031] Step 2: After contacting the inorganic alkaline aqueous solution with the organic solution (A), the step of obtaining an organic solution (B) containing an epoxy compound;

[0032] Step 3: a step of obtaining an organic solution (C) containing an epoxy compound after contacting an acidic aqueous solution containing a polymer having at least one functional group selected from carboxyl and sulfonic acid groups with the organic solution (B).

[0033] Step 1 is a step of oxidizing and converting an olefin compound as a substrate into an epoxy compound.

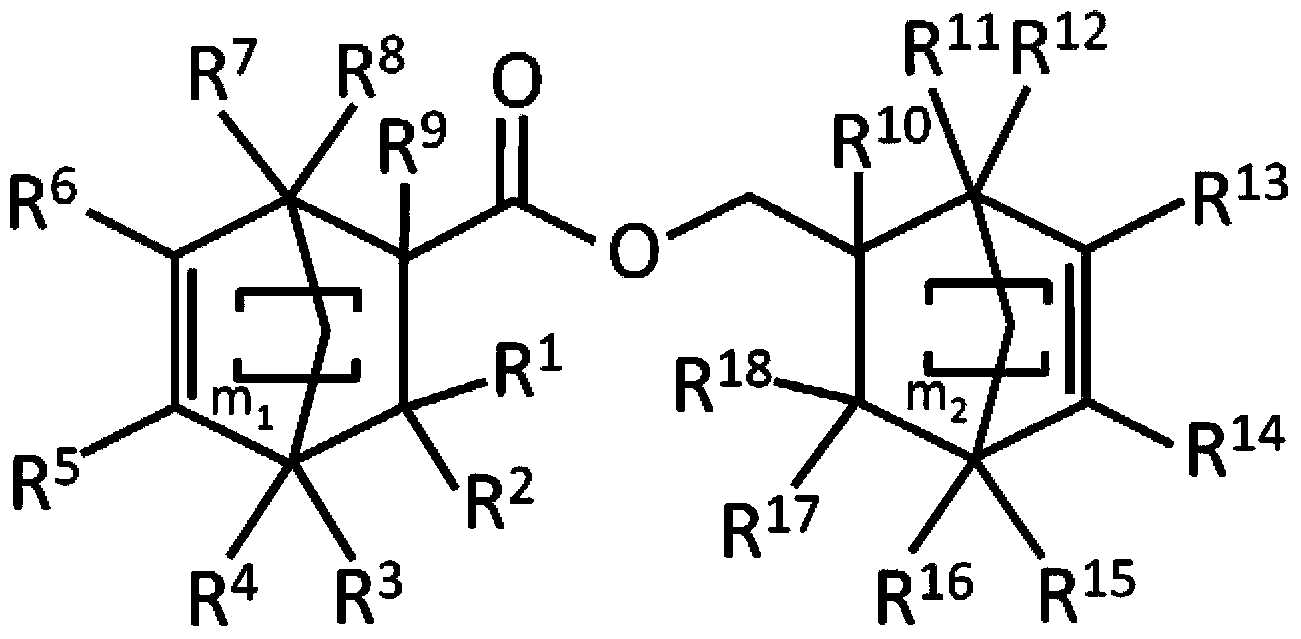

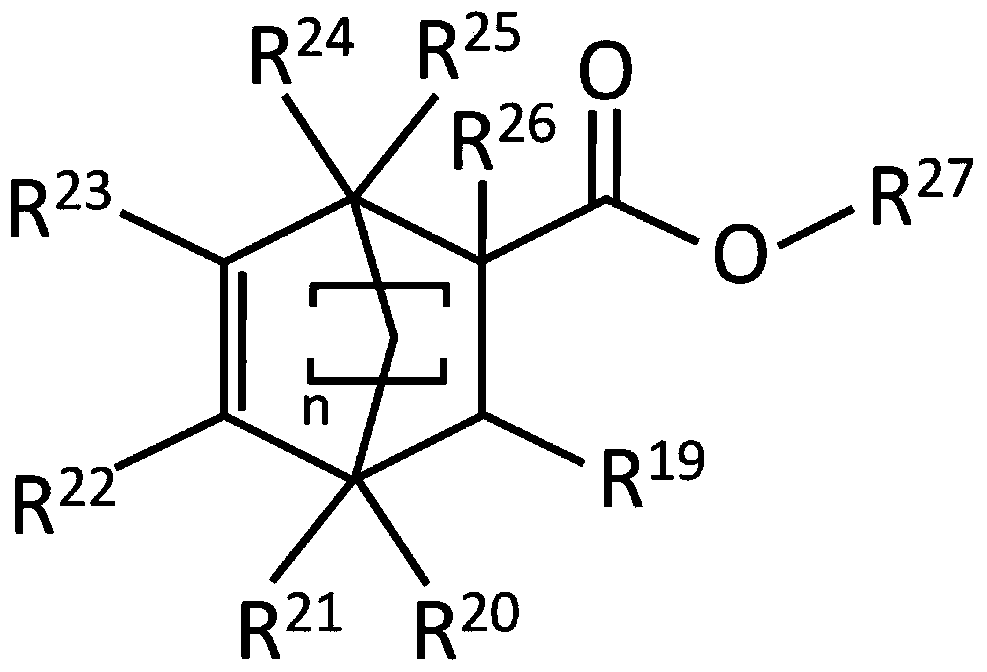

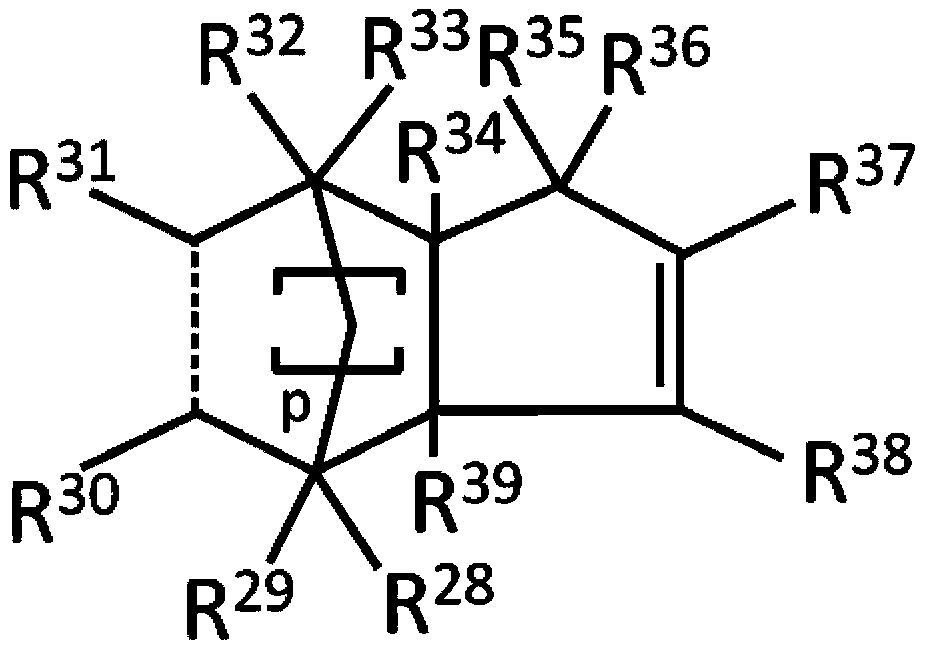

[0034] As the olefin compou...

Embodiment 1

[0178]

[0179] To a test tube with a magnetic stir bar was added 2.34 g (24.4 mmol) of 35.5% by weight hydrogen peroxide solution, 123 mg (0.24 mmol) of methyl trioctyl ammonium chloride, 80 mg (0.24 mmol) of sodium tungstate dihydrate and 141 mg of (0.6 mmol) 42.5 weight% phosphoric acid aqueous solution was stirred at room temperature for 30 minutes, and the catalyst aqueous solution was prepared by this. Next, 2.69 g (12.2 mmol) of a diene compound represented by the following structure was added to the aqueous catalyst solution ( * 1) and 2.69 g of toluene, and carried out an oxidation reaction at 50° C. for 10 hours while stirring. After completion of the reaction, the organic phase in the aqueous phase and the organic phase separated into two layers is used as an organic solution (A). The residual amount of methyltrioctylammonium chloride in this organic solution (A) was 18053 ppm.

[0180]

[0181]

[0182] Add 4.40g of 2% aqueous solution of sodium hydroxide ...

Embodiment 2

[0187] In Example 1, the polymer aqueous solution P1 (4.90g) used in step 3 was replaced by the polymer aqueous solution P6 (4.90g), except that, the same operation was carried out to obtain the epoxy compound containing the above ( ** 1) The organic solution (C). The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com