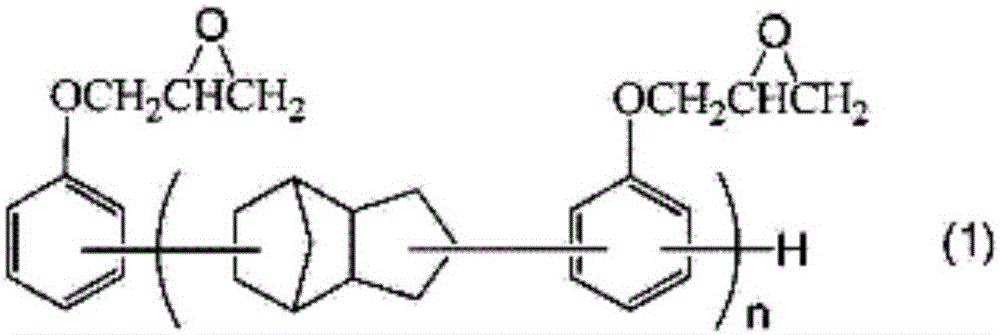

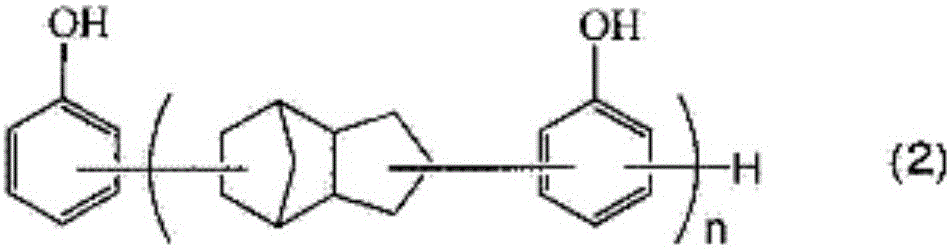

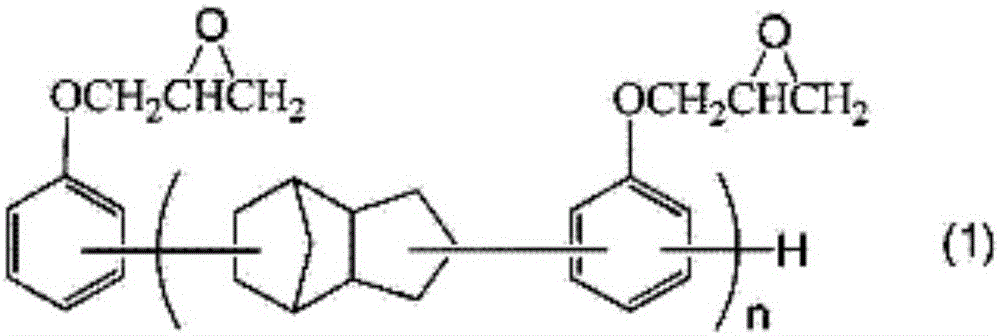

Epoxy carboxylate compound, derivative thereof, active energy ray-curable resin composition containing same, and cured product thereof

An active energy ray and epoxy carboxylate technology, applied in the field of reactive epoxy carboxylate compounds and reactive polycarboxylic acid compounds, can solve the problems of pigment dispersibility, poor sensitivity and developability, and achieve good developability, Excellent resin properties and good storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0151] Hereinafter, although an Example demonstrates this invention in detail, this invention is not limited to these Examples. In addition, in an Example, unless otherwise indicated, a part shows a mass part.

[0152] The softening point, epoxy equivalent, and acid value were measured on the following conditions.

[0153] 1) Epoxy equivalent: Measured by a method based on JIS K7236:2001.

[0154] 2) Softening point: Measured by a method based on JIS K7234:1986.

[0155] 3) Acid value: Measured by a method based on JIS K0070:1992.

[0156] 4) The measurement conditions of GPC are as follows.

[0157] Model: TOSOH HLC-8220GPC

[0158] Column: Super HZM-N

[0159] Eluent: THF (tetrahydrofuran); 0.35ml / min, 40°C

[0160] Detector: RI (differential refractometer)

[0161] Molecular weight standard: polystyrene

Synthetic example 1

[0162] Synthesis Example 1: Synthesis of Epoxy Resin

Synthetic example 1-1

[0164] Epoxy resin (X) (XD-1000 manufactured by Nippon Kayaku Co., Ltd., epoxy equivalent 254g / eq., average functional group number 2.5 , Mw / Mn value is 1.95) 187 parts, phenolic resin (Y) (Nippon Oil Corporation, DPP-6095L, hydroxyl equivalent 178g / eq., average functional group number 2.2) 13 parts, toluene 50 parts, tetramethyl 0.2 parts of ammonium chloride were reacted at 120° C. for 4 hours. After completion of the reaction, 300 parts of toluene was added, washed with water, and the obtained solution was distilled off at 180° C. under reduced pressure using a rotary evaporator to remove the solvent and the like to obtain 198 parts of the target epoxy resin (EP1). The epoxy equivalent of the obtained epoxy resin was 290 g / eq., the softening point was 92 degreeC, and the melt viscosity (200 degreeC) was 0.10 Pa*s. In addition, the value of Mw / Mn was 2.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com