Ceramic silicone rubber cable material and preparation method thereof

A ceramic silicone rubber and cable material technology, which is applied in the direction of insulating cables, rubber insulators, cables, etc., can solve the problems affecting the physical and mechanical properties and processing of cable materials, achieve excellent non-flammability, and ensure normal power transmission and power generation less smoke effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

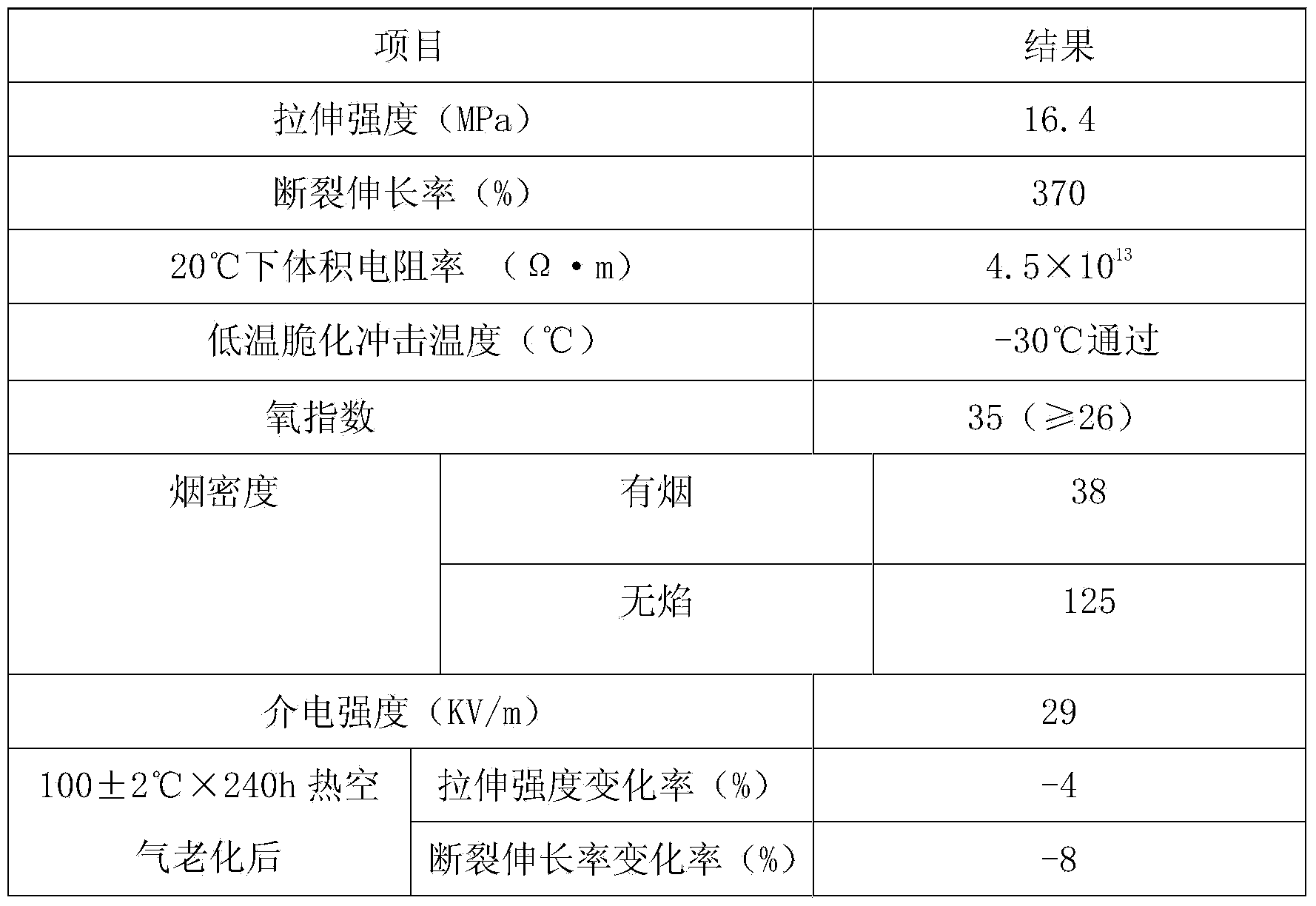

Examples

Embodiment Construction

[0013] A vitrified silicone rubber cable material, prepared from the following components in weight (kg):

[0014] Silicone rubber 88, natural rubber 15, mineral silicate 25, antimony trioxide 12, ammonium polyphosphate 16, zinc oxide 5, antioxidant DTPD1, spray carbon black 25, light calcium carbonate 18, aluminum hypophosphite 15, hard Calcium fatty acid 1, pentaerythritol 2, talcum powder 1, modified filler 13.

[0015] Wherein, the modified filler is prepared by the following method:

[0016] Calcinate the diatomite at 540°C for 3.5 hours, take it out, add 3% sodium hydroxide solution and grind it for 1.5 hours, then add 13% hydrochloric acid solution, adjust the pH value to 4-5, and age for 12 hours. Add sodium hydroxide solution to adjust the pH of the grinding liquid to be neutral, filter and dry to obtain filler powder, then, add camphor essential oil equivalent to 1% of powder weight, 1% nano-carbon, 2% aluminum hypophosphite , after grinding together for 1.5 hour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com