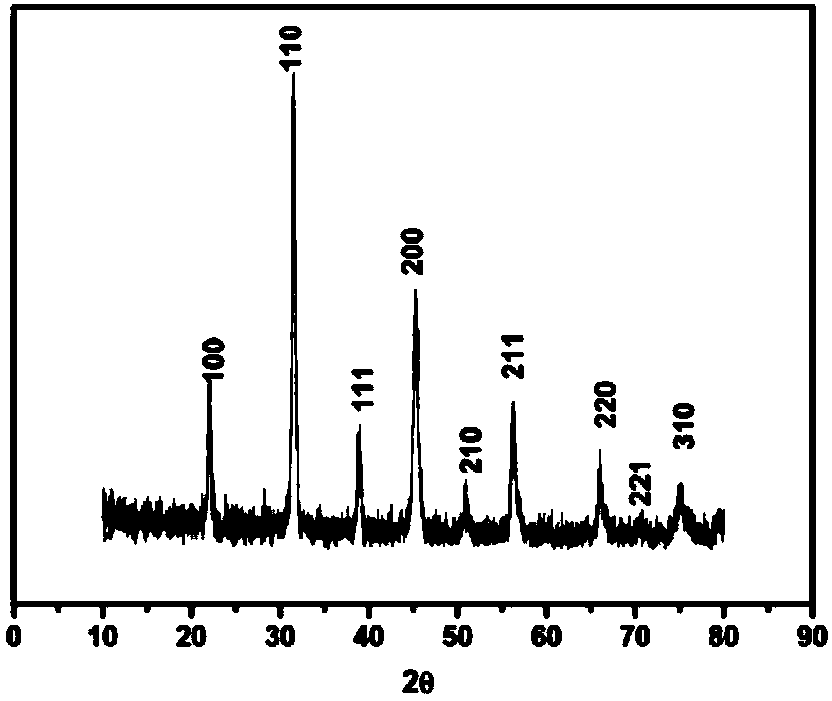

Method for synthesis of strontium-barium titanate nanotubes

A technology for synthesizing barium strontium titanate and barium strontium titanate, which is applied in the fields of filament/thread forming, textile and paper making, fiber treatment, etc., to achieve the effect of low cost and high sample purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Configure the spinning solution, first prepare the core layer spinning solution, add a certain amount of PVP to DMF (the ratio of PVP to DMF mass is 1:2), and use a magnetic stirrer to continuously stir at room temperature for 1 hour. Stirring speed is 300 revs / min, then under the condition of room temperature, leave standstill 1h, obtain PVP / DMF core layer spinning solution; Next prepare shell layer spinning solution, press Ba element, Sr element, Ti element molar ratio to be 0.6: Weigh a certain amount of Ba(COOH) at a ratio of 0.4:1 2 、Sr(COOH) 2 and C 16 h 36 o 4 Ti, then Ba(COOH) 2 、Sr(COOH) 2 Add it into glacial acetic acid (the mass ratio of salt to acetic acid is 1:5), stir continuously at 80° C. for 10 minutes with a magnetic stirrer, and the stirring speed is 300 rpm, and then stand at room temperature for 1 h to obtain the A set of solutions, the C 16 h 36 o 4 Ti is added in acetylacetone (C 16 h 36 o 4 The ratio of Ti to the mass of acetylacet...

Embodiment 2

[0035] 1. Configure the spinning solution, first prepare the core layer spinning solution, add a certain amount of PVP to DMF (the ratio of PVP to DMF mass is 1; 2.5), and use a magnetic stirrer to continuously stir at room temperature for 2 hours. Stirring speed is 350 revs / min, then leaves standstill 2h under the condition of room temperature, obtains PVP / DMF core layer spinning solution; Next prepare shell layer spinning solution, be 0.6 by Ba element, Sr element, Ti element mol ratio: 0.4:1 Weigh a certain amount of Ba(COOH) respectively 2 、Sr(COOH) 2 and C 16 h 36 o 4 Ti, then Ba(COOH) 2 、Sr(COOH) 2 Add it into glacial acetic acid (the mass ratio of salt to acetic acid is 1:6), stir continuously at 80°C for 10 minutes with a magnetic stirrer, the stirring speed is 300 rpm, and then stand at room temperature for 1h to obtain the A set of solutions, the C 16 h 36 o 4 Ti is added in acetylacetone (C 16 h 36 o 4 The ratio of Ti to acetylacetone mass is 1: 2.5), co...

Embodiment 3

[0039] 1. Configure the spinning solution, first prepare the core layer spinning solution, add a certain amount of PVP to DMF (the ratio of PVP to DMF mass is 1:2.5), and use a magnetic stirrer to continuously stir at room temperature for 2 hours. The stirring speed is 400 rev / min, and then stand at room temperature for 2h to obtain the PVP / DMF core layer spinning solution; secondly, the shell layer spinning solution is prepared, and the molar ratio of Ba element, Sr element, and Ti element is 0.5; Weigh a certain amount of Ba(COOH) at a ratio of 0.5:1 2 、Sr(COOH) 2 and C 16 h 36 o 4 Ti, then Ba(COOH) 2 、Sr(COOH) 2 Add it into glacial acetic acid (the mass ratio of salt to acetic acid is 1:8), stir continuously at 80°C for 10 minutes with a magnetic stirrer, the stirring speed is 300 rpm, and then stand at room temperature for 1h to obtain the A set of solutions, the C 16 h 36 o 4 Ti is added in acetylacetone (C 16 h 36 o 4 The ratio of Ti to acetylacetone mass is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com