A special modified bitumen waterproofing membrane based on bipv technology and preparation method thereof

A technology of modified asphalt and waterproof membrane, which is applied in the field of solar energy utilization and waterproof materials, which can solve the problems of low softening point, waterproof membrane and battery components falling off, etc., so as to improve the softening point, increase the stability of heat and humidity, and reduce the expansion range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

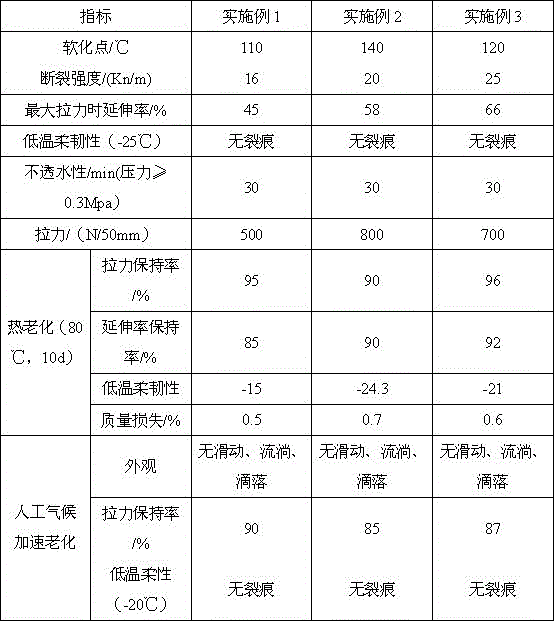

Examples

preparation example Construction

[0050] A preparation method based on BIPV technology-specific modified asphalt waterproofing membrane, comprising the following steps:

[0051] 1) Add petroleum asphalt into the reactor, heat and stir at 180~190°C for dehydration;

[0052] 2) According to the ratio in claim 1, add residual oil, SBS rubber, and silicone rubber in sequence, and keep stirring for 2 hours;

[0053] 3) Pour the processed material in step 2) into the colloid mill for grinding, and grind it in a cycle for three times, and continue to stir and disperse for 30-60 minutes after grinding;

[0054] 4) Cool down to 160°C, add coumarone resin, keep stirring for 1 hour;

[0055] 5) Add ultraviolet absorbers, antioxidants, talcum powder, stir and mix evenly, pour into the oil immersion tank;

[0056] 6) Unfold the base layer of the glass fiber reinforced polyester felt, put it into the oil immersion tank, and carry out oil immersion coating;

[0057] 7) Control the thickness of the oil-immersed coating, an...

Embodiment 1

[0065] Add 30g of petroleum asphalt into the reactor, heat and stir at 180~190°C for dehydration, add 20g of residual oil, 5g of star-shaped SBS rubber, and 2g of silicone rubber in sequence, keep stirring for 2 hours, then pour it into a colloid mill and grind it for three times. After grinding, continue to stir for 30-60 minutes, lower the temperature to 160°C, add 5 coumarone resin, keep stirring for 1 hour, then add 0.1g of antioxidant di-tert-butyl p-cresol, 5g of ultraviolet absorber Mg-Al-based LDHs compound, 20g of talcum powder, stir evenly, pour the SBS modified asphalt oil impregnation material into the oil immersion tank, unfold the tire base material, put it into the oil immersion tank, apply the oil immersion, cool, and cover with film.

[0066] The upper surface of the waterproof material layer is coated with shale isolation film, the material thickness of the waterproof layer is 1mm, the lower surface of the waterproof reinforcement layer is coated with hot-melt...

Embodiment 2

[0068] Add 60g of petroleum asphalt into the reactor, heat and stir at 180~190°C for dehydration, add 10g of residual oil, 15g of star-shaped SBS rubber, and 10g of silicone rubber in sequence, heat and stir for 2 hours, then pour it into a colloid mill and grind it for three times. After grinding, continue to stir for 30-60 minutes, cool down to 160°C, add 10g of coumarone resin, keep stirring for 1h, add 1g of antioxidant di-tert-butyl p-cresol, 2g of ultraviolet absorber Zn-Al-based LDHs compound, 10g of talc powder, stir evenly, pour the SBS modified asphalt oil immersion material into the oil immersion tank, unfold the tire base material, put it into the oil immersion tank, oil immersion coating, cooling, and film coating.

[0069] The upper surface of the waterproof material layer is coated with shale isolation film, the thickness of the waterproof layer is 2mm, the lower surface of the waterproof reinforcement layer is a hot-melt PE film, the thickness of the waterproof ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com