Method for producing fine powder of loxoprofen sodium dihydrate for pharmaceutical preparations

A technology of loxoprofen sodium dihydrate and a manufacturing method, which is applied in the field of micropowder of loxoprofen sodium dihydrate, can solve problems such as hindering processing, and achieve the effects of improving productivity, increasing productivity, and lower operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

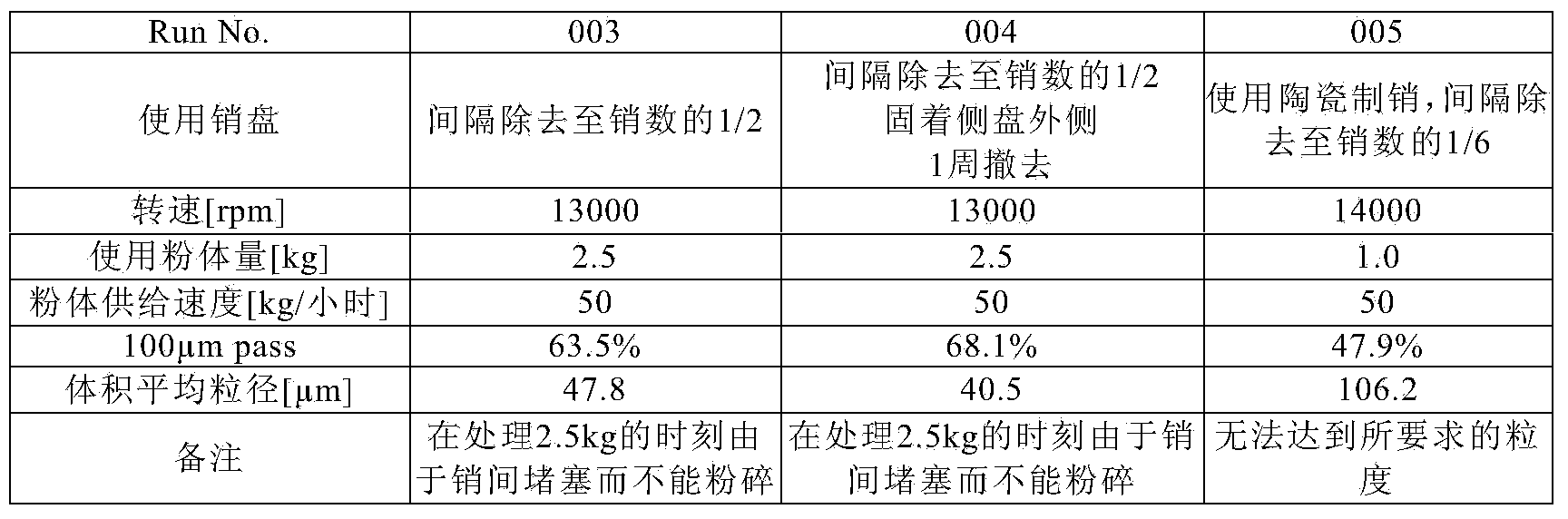

Examples

Embodiment 1

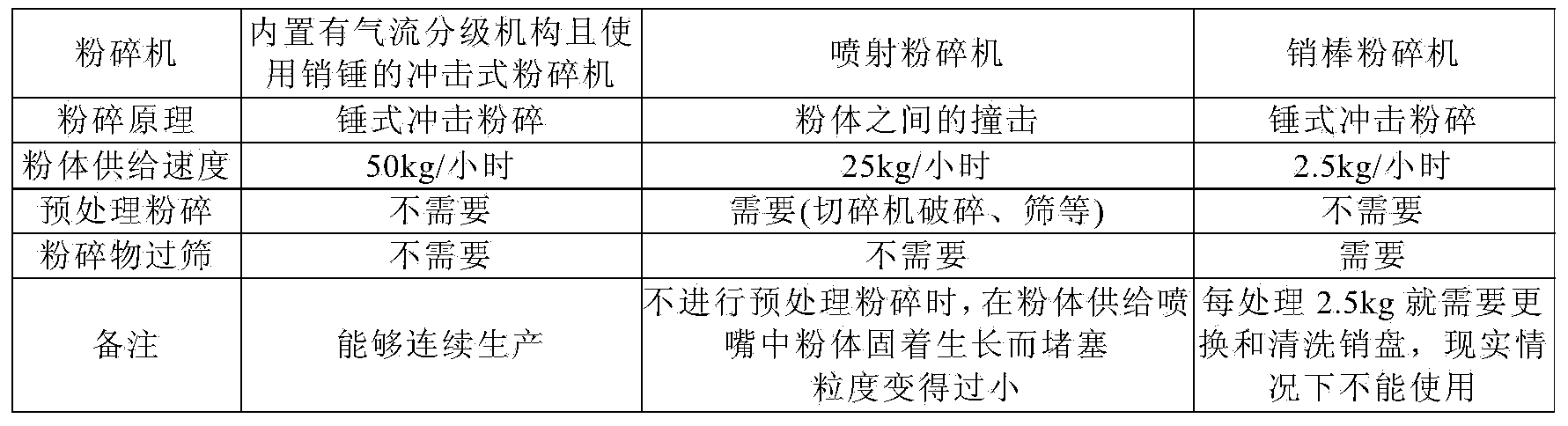

[0061] Pulverization was performed with an atomizing pulverizer which is an impact pulverizer using a pin hammer with a built-in air classification mechanism.

[0062] The crystals of loxoprofen sodium dihydrate (manufactured by Yonezawa Hamari Pharmaceutical Co., Ltd.) were pulverized using ACM Palberaiza 2EC (trade name) manufactured by Hosokawa Mikron Corporation.

[0063] Testing machine: ACM パルベライザ 2EC (trade name, manufactured by Hosokawa Micron Co., Ltd.)

[0064] Pin hammer crushing rotor: maximum speed 12000rpm

[0065] Grading rotor: maximum speed 6000rpm

[0066] Lining: Glossy Lining

[0067] Grading rotor: short type

[0068] There is no cold air in the pulverizer (room temperature is about 27° C.).

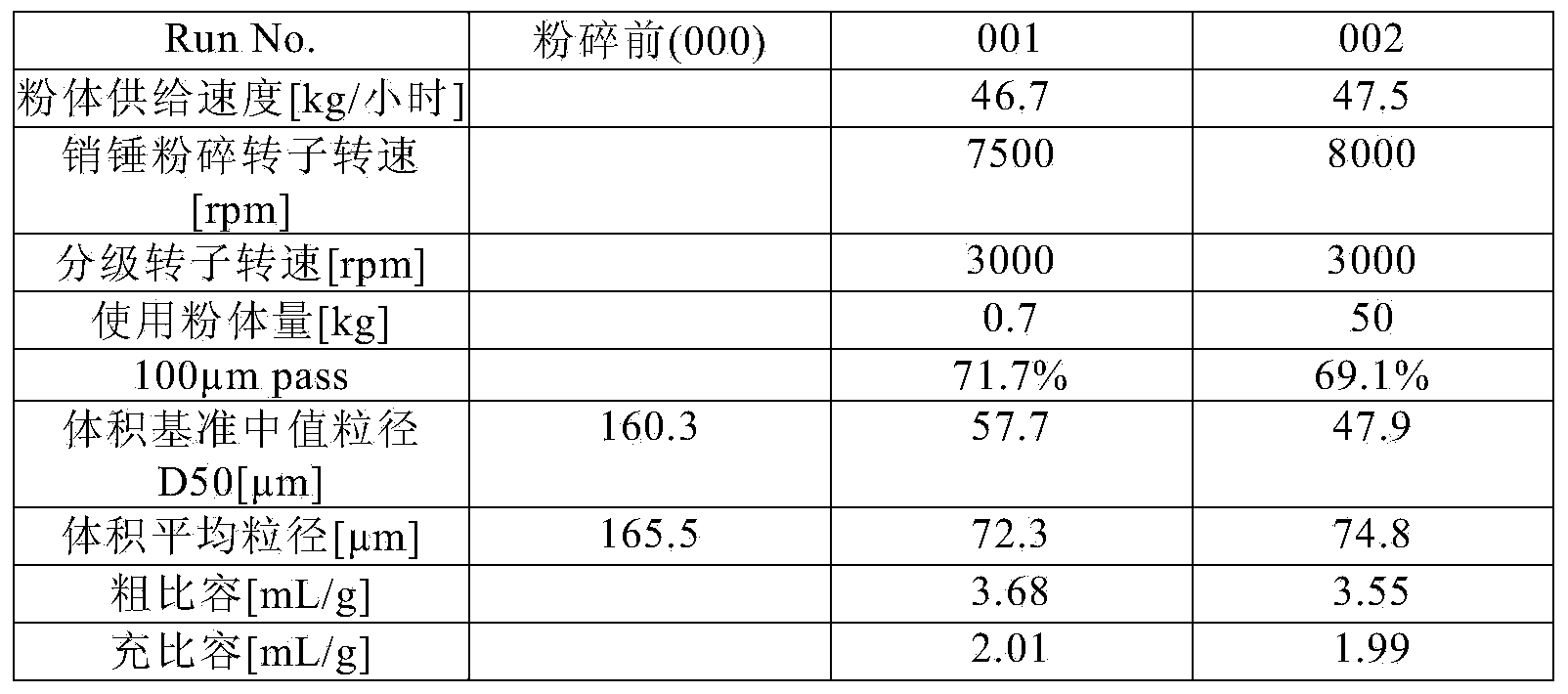

[0069] Regarding the amount of loxoprofen sodium dihydrate (used powder amount) used in the pulverization performed by the ACM パルベライザ 2EC pulverizer, the first test (Run.No.001) was 0.7 kg, and the second test ( Run.No.002) is 50kg.

[0070] Regarding the pulve...

preparation example 1

[0100] Formulation example 1 (manufacture of tablet)

[0101]

[0102] (1) to (4) were kneaded with water, vacuum-dried, and then granulated. Mix (5) with this granulated powder, and perform tableting by a tablet machine. By this method, 1600 tablets containing 70 mg of loxoprofen sodium dihydrate per 250 mg tablet were obtained.

preparation example 2

[0103] Preparation Example 2 (Manufacture of Adhesive for Adhesive Preparation)

[0104]

[0105] After mixing (2) to (4), the fine powder of loxoprofen sodium dihydrate produced in Example 1 of (1) was added and mixed to obtain a uniform adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com