Environment-friendly multifunctional composite soybean seed coating agent and processing technique thereof

An environment-friendly and processing technology, applied in the agricultural field, can solve the problems of lack of environment-friendly multifunctional soybean seed coating agent, etc., and achieve the effects of improving crop yield structure, improving immunity, increasing yield and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

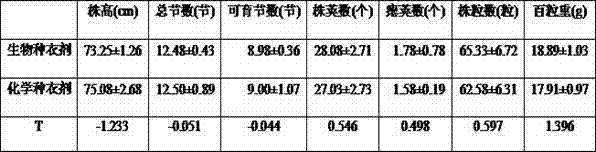

Image

Examples

Embodiment 1

[0015] The preparation method of the environment-friendly multifunctional soybean compound seed coating agent of the present embodiment is as follows:

[0016] 20% soybean rhizobium GIM1.93 fermented liquid, 10% bacillus CGMCC 1.7195 fermented liquid, 10% bacillus CGMCC 1.1870 fermented liquid, 20% jelly-like bacillus CCTCC 10013 fermented liquid, 20% by weight percentage % of the Bacillus subtilis CGMCC 1.2397 fermented liquid and 20% of the Bacillus CGMCC 1.2397 fermented liquid are mixed to obtain the microbial composite bacterial agent; by weight percentage, 83.9% of the microbial composite bacterial agent, 1% of the metal trace element solution and 10% of the The film-forming agent was mixed and shaken in a shaker for 3 hours, then added 0.1% total alkaloids of matrine, put in a shaker and shaken for 3 hours, then added 5% food-grade brilliant blue, put in a shaker and shaken for 3 hours, that is to get the finished product. The trace element solution is composed of 0.1%...

Embodiment 2

[0021] The preparation method of the environment-friendly multifunctional soybean compound seed coating agent of the present embodiment is as follows:

[0022] 20% soybean rhizobium GIM1.93 fermented liquid, 10% bacillus CGMCC 1.7195 fermented liquid, 17% bacillus CGMCC 1.1870 fermented liquid, 17% jelly-like bacillus CCTCC 10013 fermented liquid, 18% by weight % of Bacillus subtilis CGMCC 1.2397 fermented liquid and 18% of Bacillus CGMCC 1.2397 fermented liquid are mixed to obtain microbial composite bacterial agent; by weight percentage, 73.9% microbial composite bacterial agent, 10% metal trace element liquid and 15% of The film-forming agent was mixed and put into a shaker for 3 hours, then added 1% total alkaloids of matrine, put into a shaker and shaken for 3 hours, then added 0.1% food-grade brilliant blue, put into a shaker and shaken for 3 hours, that is to get the finished product. The trace element solution is composed of 2% molybdenum, 5% manganese and the rest of...

Embodiment 3

[0024]20% soybean rhizobium GIM1.93 fermented liquid, 10% bacillus CGMCC 1.7195 fermented liquid, 10-20% bacillus CGMCC 1.1870 fermented liquid, 10-20% jelly-like bacillus CCTCC 10013 Fermentation broth, 10-20% of Bacillus subtilis CGMCC 1.2397 fermentation broth and 10-20% of Bacillus CGMCC 1.2397 fermentation broth are mixed to obtain a microbial composite bacterial agent; by weight percentage, 70% of the microbial composite bacterial agent, 9% of Metal trace element solution and 15% film-forming agent were mixed and put into a shaker for 3 hours, then added 1% of Sophora flavescens, put into a shaker and shaken for 3 hours, then added 5% of food-grade brilliant blue, put Enter the shaker and shake for 3 hours to obtain the finished product. The trace element solution is composed of 1.5% molybdenum, 3% manganese and the rest of water by weight percentage; the film-forming agent is composed of 8% polyvinyl alcohol 17-88, 6% polyvinyl alcohol Vinyl alcohol 17-99 and the remai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com