Separation method of ethylenediamine and water azeotrope

A separation method, the technology of ethylenediamine, applied in the purification/separation of amino compounds, organic chemistry, etc., can solve the problems of high energy consumption and impact on application, and achieve the effect of low energy consumption and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

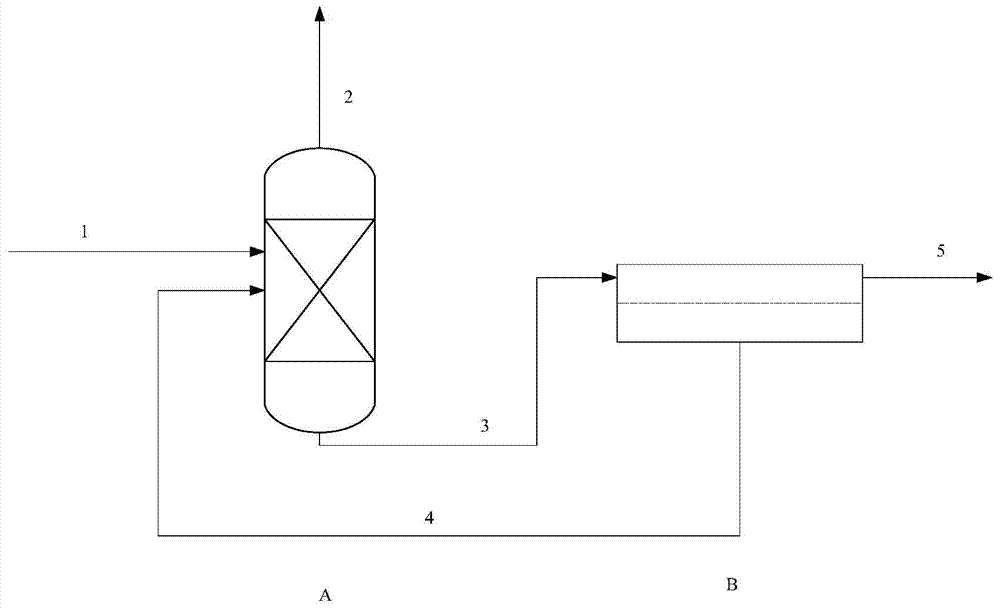

[0024] The mixture whose mass percentage content is 70% of ethylenediamine and 30% of water is fed from the middle part of rectifying tower A under the condition of temperature of 80 ℃. is 2, the top temperature of the tower is 100 °C, the top of the A tower is water, and the purity is 99.9%; the temperature of the tower A of the rectification tower is 120 °C, and the tower still is an azeotrope of ethylenediamine and water.

[0025] The temperature of the azeotrope of ethylenediamine and water drops to 60 °C, and enters the pervaporation device B. The feed liquid side is operated at a pressure of 100 kPa. The operating temperature of the feed liquid is measured at 60 °C, and the pressure after the membrane is 0.5 kPa. After the permeate is condensed, it returns to In the rectifying tower A, the retentate is ethylenediamine product with a purity of 99.9%.

Embodiment 2

[0027] The mass percentage content is that the mixture of ethylenediamine 75% and water 25% is fed from the middle of rectifying tower A under the condition of temperature of 90 ℃. is 3, the tower top temperature is 105 ℃, the A tower top is water, and the purity is 99.9%; the A tower still temperature of the rectification tower is 125 ℃, and the tower still is the azeotrope of ethylenediamine and water.

[0028] The temperature of the azeotrope of ethylenediamine and water drops to 60 °C, and enters the pervaporation device B. The feed liquid side is operated at a pressure of 120 kPa. The operating temperature of the feed liquid is measured at 60 °C, and the pressure behind the membrane is 1 kPa. In distillation column A, the retentate is an ethylenediamine product with a purity of 99.6%.

Embodiment 3

[0030] The mixture whose mass percentage content is 80% of ethylenediamine and 20% of water is fed from the middle of rectifying tower A under the condition of temperature of 95 ℃. For 5, A tower top, the tower top is water, the temperature is 120 ℃, the purity is 99.9%; the temperature of the distillation tower A tower still is 140 ℃, and the tower still is the azeotrope of ethylenediamine and water.

[0031] The temperature of the azeotrope of ethylenediamine and water drops to 60 °C, and enters the pervaporation device B. The feed liquid side is operated at a pressure of 200 kPa. The operating temperature of the feed liquid is measured at 70 °C, and the pressure after the membrane is 2 kPa. In distillation column A, the retentate is an ethylenediamine product with a purity of 99.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com