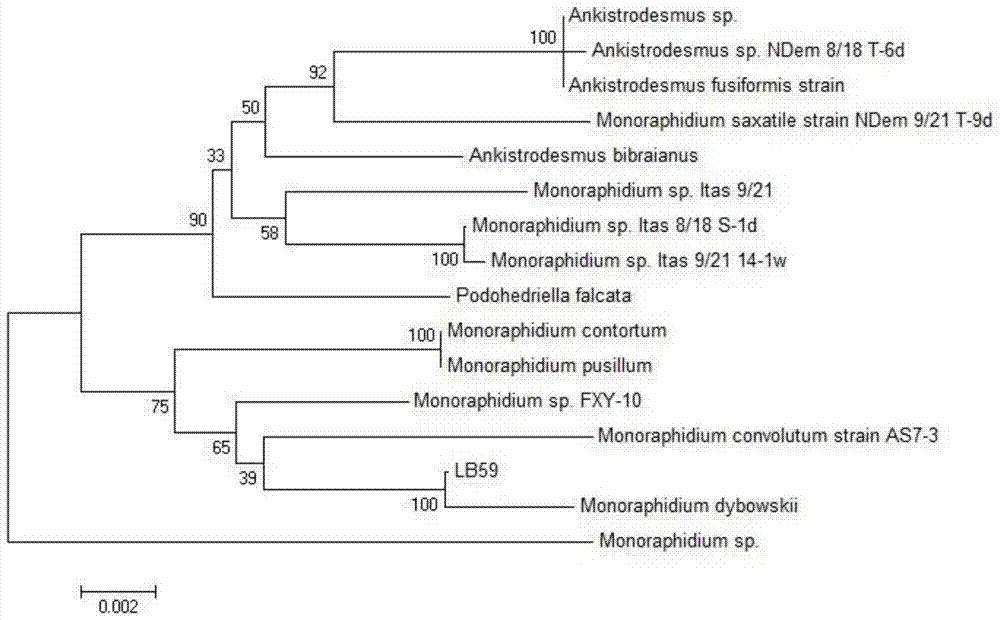

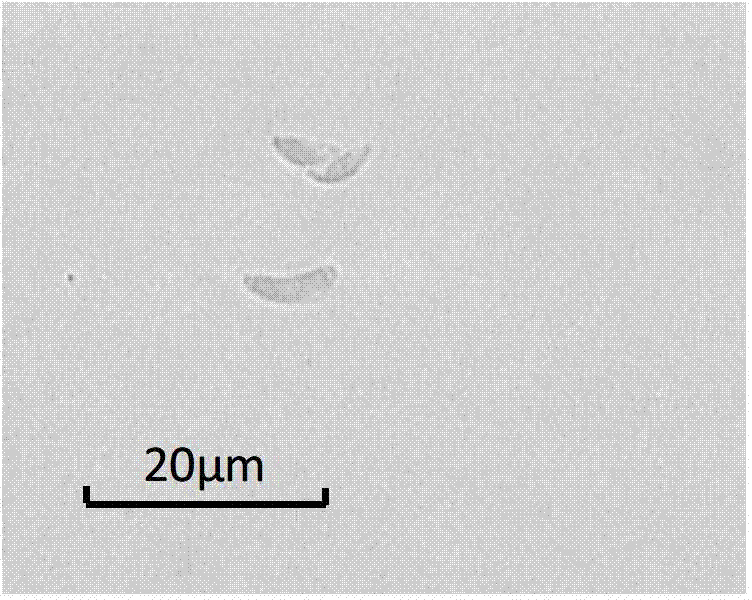

Obtaining and application of oil-producing monoraphidium LB59

A technology of monopods and algae strains, which is applied in the field of screening and cultivation of oleaginous microalgae to achieve the effect of preventing damage and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0040] Example 1. Semi-continuous cultivation in a circular photoreactor

[0041] Prepare the culture medium according to the medium formula described above, at 0.1m 2 Inoculate and cultivate in a circular photoreactor, and the volume of the culture medium is 20L. Initial OD 680 The value is 0.05, the temperature is controlled at 30-35°C, and the light intensity is 200μE / m 2 s continuous light, pass CO2 into the culture medium for 1 hour every day 2 , and sample OD every day 680 value, OD 680 When the value reaches 6.0, collect 1 / 2 of the algae liquid and supplement 1 / 2 of fresh medium for semi-continuous culture, and then collect the algae liquid every 5 days to feed the same volume of medium. Adjust the pH to 6 with dilute hydrochloric acid in the collection container, add chitosan to 5.0 mg / L, and the flocculation and sedimentation efficiency reaches over 90% in 30 minutes; remove the supernatant from the flocculated algae liquid to obtain concentrated algae Cells, fr...

example 2

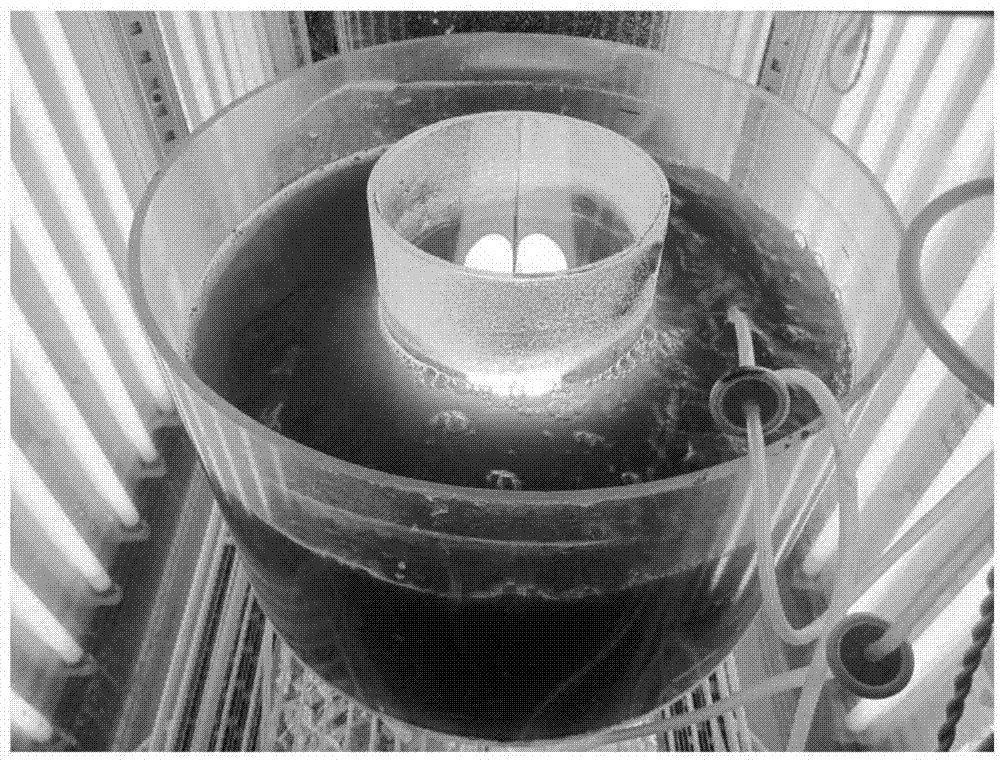

[0044] Example 2. Outdoor track pool cultivation

[0045] According to the medium formula of the algae strain, the local groundwater in Inner Mongolia was used to prepare the culture medium, and the outdoor area of Ordos, Inner Mongolia was 5m 2 Runway pools for open culture (see Figure 4), the volume of culture medium is 750L. The flow rate of the runway pool is controlled by a wheel-shaped agitator to 0.04m / s; the water temperature is about 30°C during the day and about 24°C at night; the light intensity varies with the weather, and the average light intensity during the day is 600μE / m 2 s, in a dark state at night; sample and measure OD every day 680 value, when cultured to OD 680 When the value reaches 2.0, start to collect 1 / 5 of the volume of algae cell liquid, then add 1 / 5 of the fresh culture liquid for semi-continuous culture, and then collect feed once every 3 days. The collected algae liquid is observed under a microscope and maintains more than 99% pure spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com