Track bed ice-melting water-draining protection device

A protective device and ice-melting technology, which is applied to roads, tracks, climate change adaptation, etc., can solve problems such as short service life, poor waterproof performance, and difficult construction, and achieve long service life, easy cleaning, and fewer types of parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

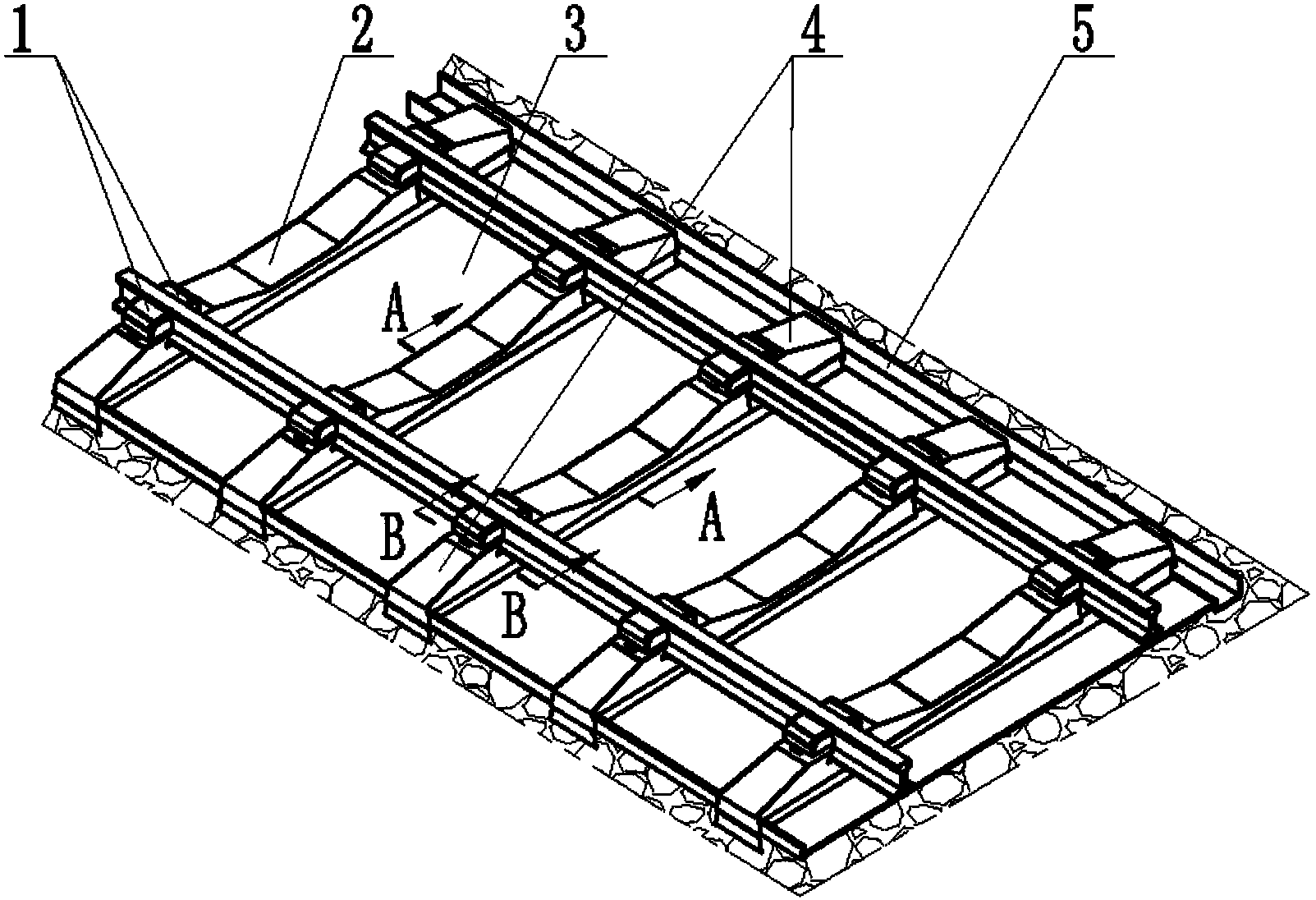

Embodiment 1

[0035] This embodiment is located in a dust suppression station at the starting point of railway coal transportation in a certain place in North China. The station sprays dust suppression fluid on trains transporting coal. The train is a special train for heavy-duty coal transportation, and the speed of the train during spraying operation is 10km / h. The railway line is ballast bed, reinforced concrete sleeper. The design requires the use of the unilateral drainway bed protection device of the present invention, without considering the melting of ice in winter. The cross-section of the sleeper is trapezoidal, and the height of each part is different; the length of the sleeper is 2650mm, the distance between the sleepers (center distance) is 658mm, and the average distance between the sides of two adjacent sleepers is 405mm.

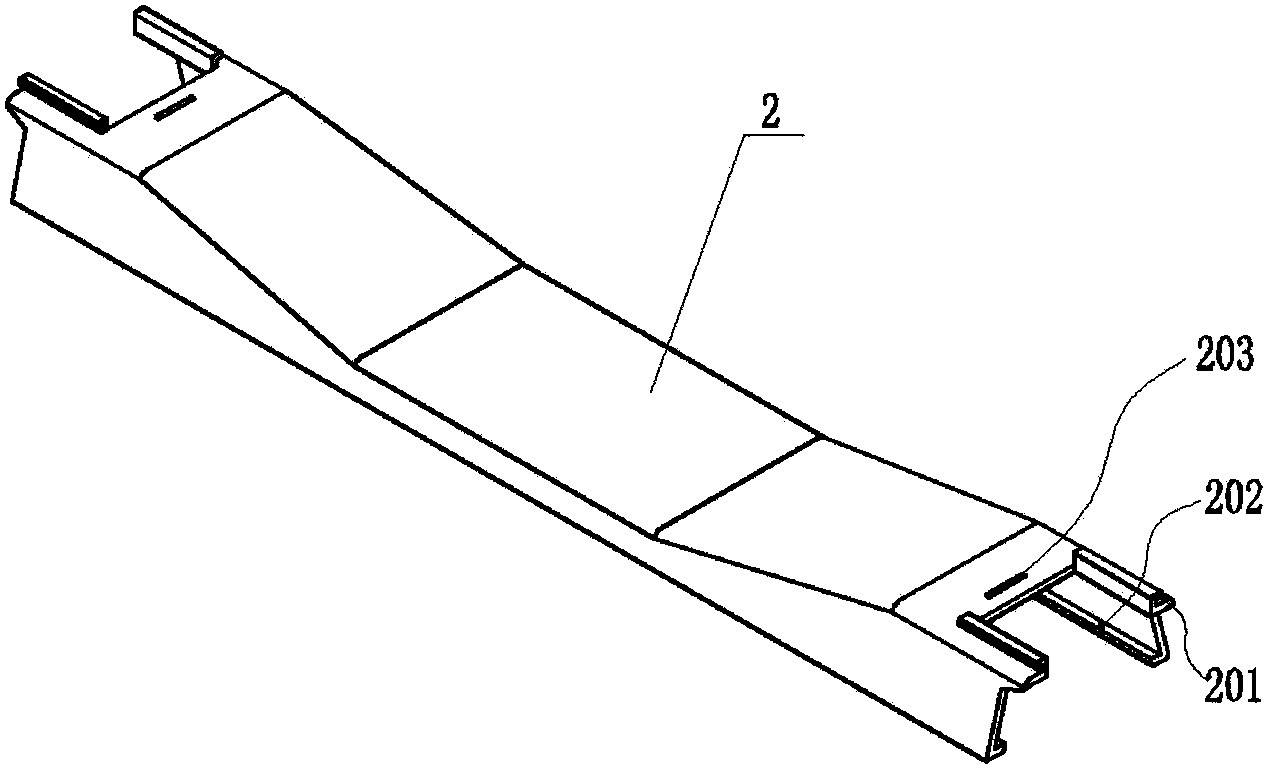

[0036]Depend on figure 1 , Figure 4 and Figure 7 As shown, the present embodiment is made up of components such as pallet shield 1, sleeper shield ...

Embodiment 2

[0052] This embodiment is applied to a mountainous section of a railway in the alpine region of northern my country. In summer, part of the road section has waterfall water splashing down on the track bed, and snow often occurs in winter. The track bed is protected by melting ice, melting snow and drainage by adopting the present invention.

[0053] The technical parameters of the ballast bed, the sleeper and each component of this embodiment are the same as those of Embodiment 1.

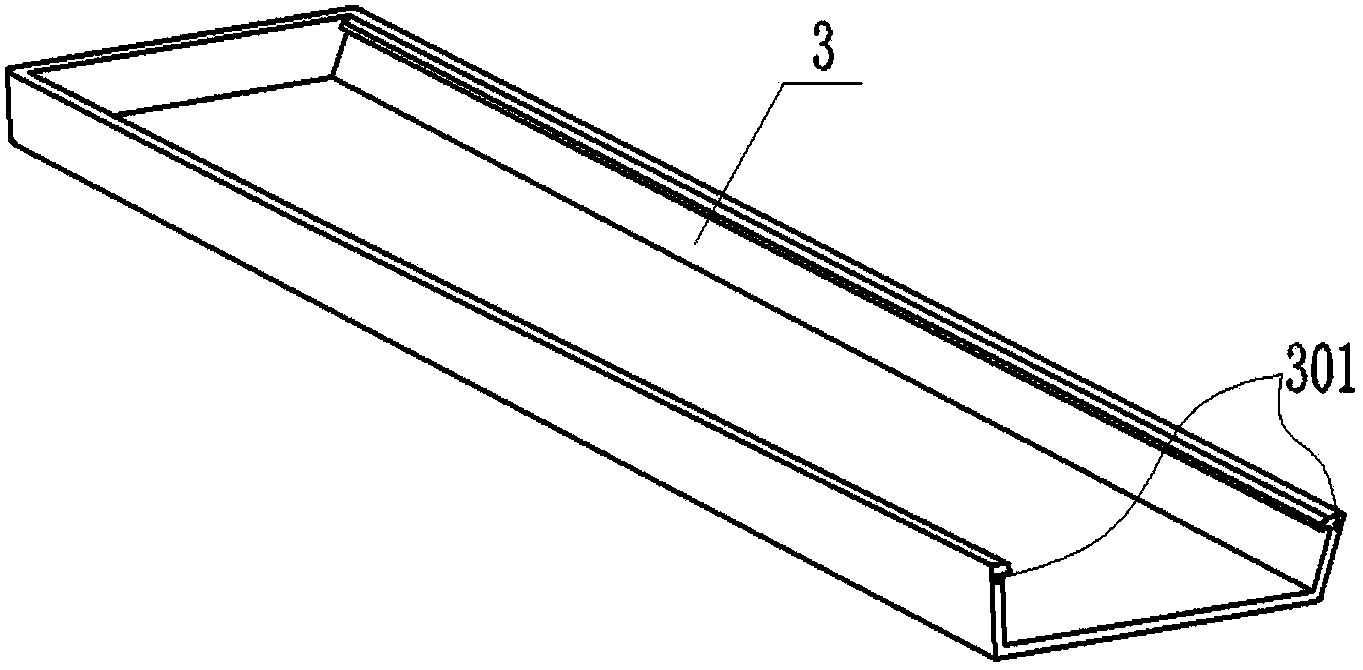

[0054] This embodiment puts forward the technical requirements for melting ice and snow in winter. Depend on Figure 11~Figure 13 As shown, a carbon fiber electric heating plate 7 is added between the sandwich layers 13 of the sleeper cover 2 and the drainage groove 3, and the layer structure is: 0.5mm wear-resistant and anti-aging gel coat layer 11+3mm reinforcement layer 12 +3mm (sandwich layer 13 / carbon fiber heating plate 7) +3mm reinforcement layer 12. The specification of the carbon fiber ...

Embodiment 3

[0062] This embodiment adopts double-sided drainage, by Figure 8 As shown, drainage ditches 5 are arranged on both sides of the ballast bed in this embodiment; bilateral drainage grooves 3a are arranged between the sleepers.

[0063] The technical parameters of the ballast bed, the sleeper and each component of this embodiment are the same as those of Embodiment 1.

[0064] The manufacturing and installation process of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com