Method for assessing integral states of furnace conditions by aid of pattern recognition technology

A technology of pattern recognition and overall status, applied in database models, special data processing applications, instruments, etc., can solve problems such as the gap between judgment and control, rising consumption, and destruction of production organization, so as to achieve accurate furnace condition evaluation results and reduce Possibilities, Effects of Improving Accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

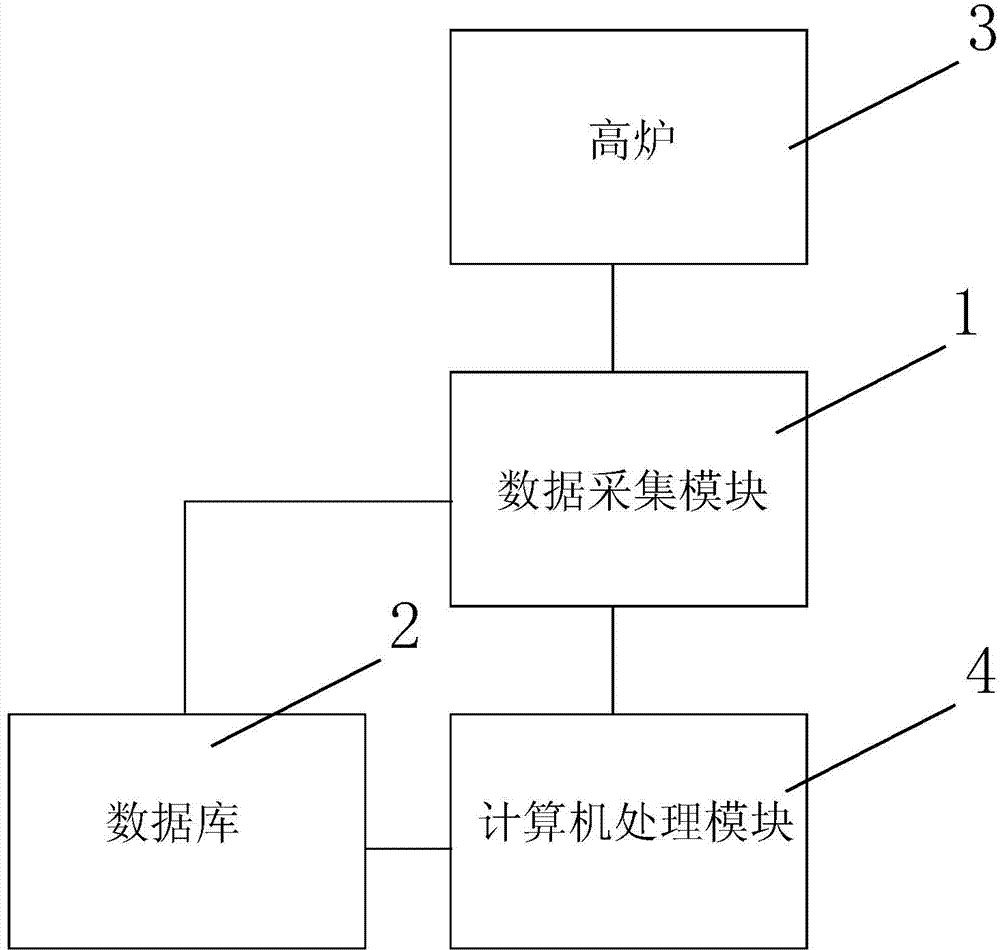

[0023] Blast furnace status: The stability of blast furnace operation is for volumes greater than 2000m 3 The blast furnace has special importance. Once the large blast furnace fails, it will seriously interfere with the production and operation of the entire iron and steel complex. The example here is aimed at 2000m 3The above large blast furnaces are equipped with complete primary automation (programmable logic controller for equipment control, DCS (distributed control systems, distributed control system)) and secondary automation, of which the secondary automation is equipped with complete database system, such as Oracle database, SQL database, this embodiment system includes a data acquisition module 1 for obtaining data from the blast furnace 3, a database 2 connected with the data acquisition module 1, a computer processing module connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com