Novel feed additive and preparation method thereof

A feed additive and new technology, applied in animal feed, animal feed, application and other directions, can solve the problems of environmental pollution, health hazards, excessive zinc content in soil, etc., and achieve the effect of protecting the environment, saving resources, and improving the use effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

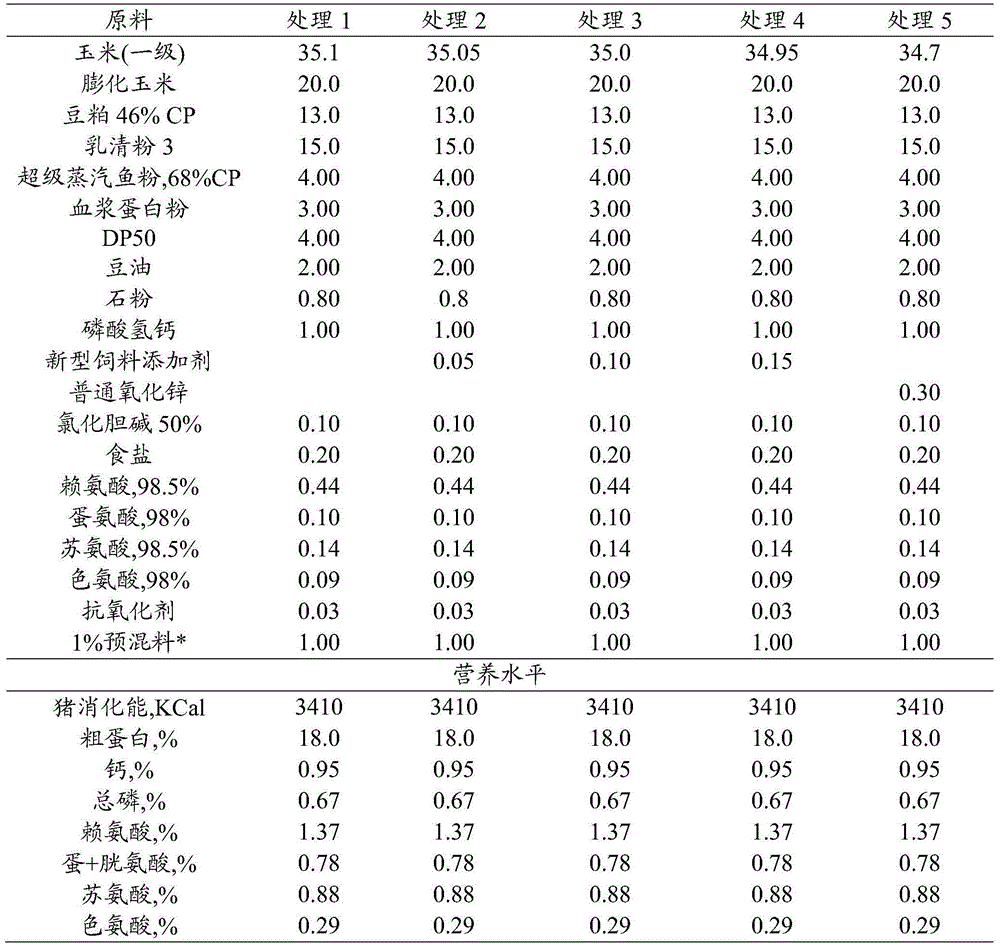

Examples

Embodiment 1

[0025] The additive includes enteric-coated nano-zinc oxide particles, which are nano-zinc oxide core particles, small intestine coating layer, middle nano-zinc oxide layer and gastric coating layer from the inside to the outside; the nano-zinc oxide core particles The components are nano-zinc oxide, maltodextrin and hydroxypropyl methylcellulose; the components of the small intestine coating layer are ethyl cellulose and cross-linked sodium carboxymethyl cellulose; the middle nano-zinc oxide layer The composition of the composition is nano zinc oxide; the composition of the gastric coating layer is acrylic resin, cross-linked sodium carboxymethylcellulose and hypromellose.

[0026] This novel feed additive is prepared according to the following steps:

[0027] (a) Mix 90% nano-zinc oxide, 5% maltodextrin, and 5% hydroxypropyl methylcellulose evenly and put them into a centrifugal granulator to make small particles of 30-80 mesh. The particle size of nano-zinc oxide is 1- 100...

Embodiment 2

[0032] This novel feed additive is prepared according to the following steps:

[0033] (a) Mix 98% nano-zinc oxide, 1% maltodextrin, and 1% hydroxypropylmethylcellulose evenly and put them into a centrifugal granulator to make small particles of 30-80 mesh.

[0034] (b) Use 10% ethyl cellulose, 2% croscarmellose sodium, and 88% ethanol to prepare a coating solution; put the small particles prepared in step (a) into a fluidized coating pan, Spray the coating solution with a spray gun; the first coating ends after the small particles gain 8% in weight;

[0035] (c) Put 60% of the zinc oxide particles after the first coating and 40% of the nano zinc oxide powder into the shot blasting machine to make particles;

[0036] (d) Use 10% acrylic resin, 2% croscarmellose sodium, 1% hypromellose, and 87% ethanol to make a coating solution, and put the zinc oxide particles into the fluidized bed coating pan , spray the coating solution with a spray gun;

[0037] (e) After the zinc oxid...

Embodiment 3

[0038] This novel feed additive is prepared according to the following steps:

[0039] (a) Mix 94% nano-zinc oxide, 3% maltodextrin, and 3% hydroxypropyl methylcellulose evenly and put them into a centrifugal granulator to make small particles of 30-80 mesh.

[0040] (b) Use 5% ethyl cellulose, 5% croscarmellose sodium, and 90% ethanol to prepare a coating liquid; put the small particles prepared in step (a) into a fluidized coating pan, Spray the coating solution with a spray gun; the first coating ends after the weight of the small particles increases by 2-8%;

[0041] (c) Put 60% of the zinc oxide particles after the first coating and 40% of the nano zinc oxide powder into the shot blasting machine to make particles;

[0042] (d) Use 20% acrylic resin, 5% croscarmellose sodium, 5% hypromellose, and 70% ethanol to make a coating liquid, and put the zinc oxide particles into the fluidized bed coating pan , spray the coating solution with a spray gun;

[0043] (e) After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com