Production process of on-board euphausia superba mince

An Antarctic krill and minced shrimp technology, which is used in food ingredients as antifreeze, food preparation, food science and other directions to achieve the effect of optimizing the formulation of antifreeze, reducing content and reducing loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

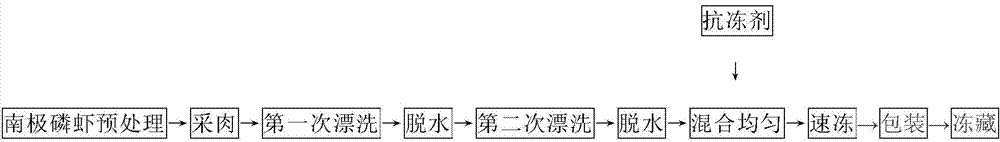

[0015] For the production process of Antarctic krill minced shrimp, see figure 1 , including the following steps:

[0016] 1. Pretreatment of Antarctic krill: The freshly caught Antarctic krill is transported by a conveyor belt, washed with seawater during the transmission process, screened and graded, and debris and miscellaneous fish are sorted out.

[0017] 2. Production of Antarctic krill minced shrimp: Collect the pretreated Antarctic krill meat and remove the shrimp shell; rinse the collected Antarctic krill meat with fresh water or sea water below 1°C for the first time, and rinse it in the rinsing water Adding mass percentage is 0.2% CaCl 2 , the amount of rinsing water is 3-4 times the weight of the shrimp meat, slowly stirred for 5 minutes, left to settle for 10 minutes and then dehydrated; then use 3-4 times the fresh water or seawater below 1°C for the second rinse, dehydrated to obtain Antarctic phosphorus Shrimp Shrimp.

[0018] 3. Add 4wt% sucrose, 4wt% sorbi...

Embodiment 2

[0020] Add 0.3wt% CaCl to the rinse water mass in the first rinse 2 , Step 3 Add 5wt% sucrose, 5wt% sorbitol, 0.3wt% polyphosphate, 0.3wt% sodium alginate and 0.4wt% carrageenan to the Antarctic krill minced shrimp, mix well , sealed package after quick freezing, frozen storage below -24 ℃. All the other steps are with embodiment 1, and this example is in the first rinsing of CaCl 2 The dosage is higher than that of Example 1, the amount of antifreeze added is higher than that of Example 1, and the effect is slightly better than that of Example 1 on defluorination and resistance to protein denaturation, but the cost is slightly increased.

Embodiment 3

[0022] Add rinsing water quality 0.1wt% CaCl in the first rinsing water, step 3 adds Antarctic krill minced shrimp quality 3wt% sucrose, 3wt% sorbitol, 0.2wt% polyphosphate, 0.1 Wt% sodium alginate and 0.2wt% carrageenan, mixed evenly, sealed and packaged after quick freezing, and stored in a freezer below -24°C. All the other steps are with embodiment 1, and this example is in the first rinsing of CaCl 2 The dosage is lower than that of Example 1, the amount of antifreeze added is lower than that of Example 1, and the effect is slightly worse than that of Example 1 in terms of defluorination and resistance to protein denaturation, but the cost is slightly reduced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com