Method for preparing composite material for radiator

A technology for composite materials and radiators, which is applied in the field of preparation of composite materials for radiators, can solve the problems of difficult control of the composite rate, difficult to form, and high equipment requirements, and achieves good vacuum brazing performance, stable vacuum brazing performance, excellent The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

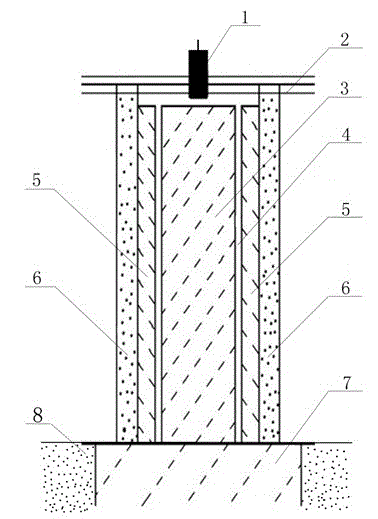

[0023] like figure 1 Shown, a kind of preparation method of radiator composite material, it comprises the following steps:

[0024] The first step, raw material surface treatment:

[0025] Take a core material ingot 3 with a length of 3000mm, a width of 800mm, and a thickness of 300mm. The core material ingot 3 is a 1-series 1060 ingot, and a hot-rolled leather plate with a length of 3000mm, a width of 800mm, and a thickness of 30mm 5. The hot-rolled steel plate 5 is made of 4 series 4104 alloy hot-rolled plate, and the pre-composited surface of the core material ingot 3 is milled until the surface has no defects such as casting segregation, microcracks, small surface protrusions, and bending. The pre-composite surface of the hot-rolled plate 5 is polished and brushed until fresh metal is exposed;

[0026] The second step, explosive compounding:

[0027] First, the base 7 is fixedly placed in the sand pile 8, then the skin material hot-rolled plate 5 obtained in the first s...

Embodiment 2

[0033] like figure 1 Shown, a kind of preparation method of radiator composite material, it comprises the following steps:

[0034] The first step, raw material surface treatment:

[0035] Take a core material ingot 3 with a length of 4000mm, a width of 1000mm, and a thickness of 350 mm. The core material ingot 3 is a 1-series 1060 ingot, and a skin material hot-rolled plate with a length of 4000mm, a width of 1000mm, and a thickness of 40mm 5. The hot-rolled steel plate 5 is made of 4 series 4104 alloy hot-rolled plate, and the pre-composited surface of the core material ingot 3 is milled until the surface has no defects such as casting segregation, microcracks, small surface protrusions, and bending. The pre-composite surface of the hot-rolled plate 5 is polished and brushed until fresh metal is exposed;

[0036] The second step, explosive compounding:

[0037] First, the base 7 is fixedly placed in the sand pile 8, then the skin material hot-rolled plate 5 obtained in th...

Embodiment 3

[0043] like figure 1 Shown, a kind of preparation method of radiator composite material, it comprises the following steps:

[0044] The first step, raw material surface treatment:

[0045] Take a core material ingot 3 with a length of 5000mm, a width of 1200mm, and a thickness of 400 mm. The core material ingot 3 is a 1-series 1060 ingot, and a skin material hot-rolled plate with a length of 5000mm, a width of 1200mm, and a thickness of 50mm 5. The hot-rolled steel plate 5 is made of 4 series 4104 alloy hot-rolled plate, and the pre-composited surface of the core material ingot 3 is milled until the surface has no defects such as casting segregation, microcracks, small surface protrusions, and bending. The pre-composite surface of the hot-rolled plate 5 is polished and brushed until fresh metal is exposed;

[0046] The second step, explosive compounding:

[0047] First, the base 7 is fixedly placed in the sand pile 8, then the skin material hot-rolled plate 5 obtained in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com