Organic compound foliage fertilizer and preparation method thereof

A foliar fertilizer, organic technology, applied in the field of organic compound foliar fertilizer and its preparation, can solve the problems of discarding leftovers, polluting the environment, etc., and achieve the effects of promoting germination, increasing germination rate and germination index, and promoting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

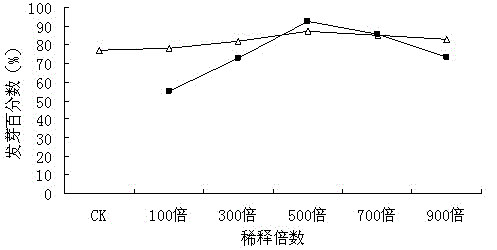

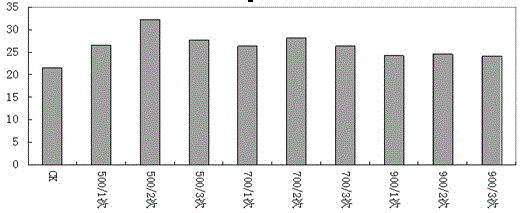

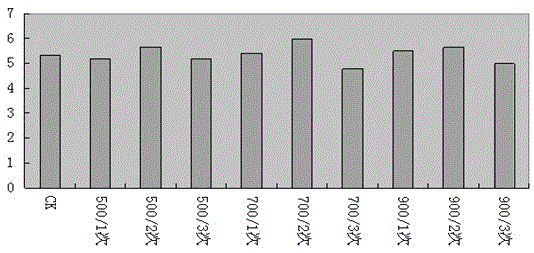

Image

Examples

Embodiment 1

[0019] 1. Preparation of Compound Amino Acids

[0020] Weigh 100g of dried and pulverized kitchen waste samples, add 550mL of sulfuric acid solution with a mass fraction of 20%, add 2-3g of zeolite, stir, and hydrolyze at 85°C for 12h. After hydrolysis, cool to room temperature. The hydrolyzate uses Ca(OH) with a mass fraction of 30% 2 The solution was neutralized to a pH value of 7, filtered to remove calcium sulfate and unhydrolyzed impurities, and the obtained filtrate was the compound amino acid solution, which was concentrated by evaporation and dried in a thermostat at 45°C for 5 hours to obtain the compound amino acid product.

[0021] 2. Preparation of Nicotine Extract

[0022] Weigh 20g of discarded tobacco leaves and transfer them into a 250ml volumetric flask, add 200ml of hydrochloric acid solution with a mass concentration of 0.03g / ml, shake well for 10min, put it in a constant temperature water bath at 70°C, and extract for 1.5h. After the extraction, the pH o...

Embodiment 2

[0041] 1. Preparation of Compound Amino Acids

[0042] Weigh 100g of dried and pulverized kitchen waste samples, add 350 mL of sulfuric acid solution with a mass fraction of 45%, add 2-3g of zeolite, stir, and hydrolyze at 100°C for 8 h; after hydrolysis, cool to room temperature; The hydrolyzate uses Ca(OH) with a mass fraction of 30% 2 The solution was neutralized to a pH value of 7, filtered to remove calcium sulfate and unhydrolyzed impurities, and the resulting filtrate was a compound amino acid solution, which was evaporated and concentrated and then dried in a thermostat at 50°C for 3 hours to obtain a compound amino acid product;

[0043] 2. Preparation of Nicotine Extract

[0044] Weigh 20g of discarded tobacco leaves and transfer them into a 250ml volumetric flask, add 150ml of hydrochloric acid solution with a mass concentration of 0.05g / ml, shake well for 10min, put it in a constant temperature water bath at 85°C, and extract for 0.5h; Finally, use a sodium hydro...

Embodiment 3

[0076] 1. Preparation of Compound Amino Acids

[0077] Weigh 100g of dried and pulverized kitchen waste samples, add 450 mL of sulfuric acid solution with a mass fraction of 30%, add 2-3g of zeolite, stir, and hydrolyze at 90°C for 10 hours; after hydrolysis, cool to room temperature; Liquid with a mass fraction of 30% Ca(OH) 2 The solution was neutralized to a pH value of 7, filtered to remove calcium sulfate and unhydrolyzed impurities, and the resulting filtrate was a compound amino acid solution, which was evaporated and concentrated and then dried in a thermostat at 48°C for 4 hours to obtain a compound amino acid product;

[0078] 2. Preparation of Nicotine Extract

[0079] Weigh 20g of discarded tobacco leaves and transfer them into a 250ml volumetric flask, add 180ml of hydrochloric acid solution with a mass concentration of 0.04g / ml, shake well for 10min, put it in a constant temperature water bath at 78°C, and extract for 1h; , use a sodium hydroxide solution with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com