Halogen-free epoxy resin composition for IC packaging

A technology based on epoxy resin and epoxy resin, which is applied in the direction of electrical components, circuits, and electrical solid devices, can solve the problems of IC packaging development limitations, and achieve improved flame retardancy, good electrical properties, and high glass transition temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

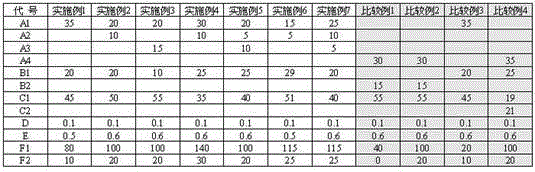

[0033] A halogen-free epoxy resin composition for IC packaging, comprising:

[0034] (A) epoxy resin

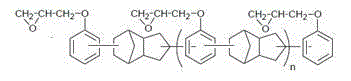

[0035] A1: Naphthalene ring epoxy resin

[0036] A2: Tetramethylbiphenyl epoxy resin

[0037] A3: Trifunctional epoxy resin

[0038] A4: BPA type epoxy resin

[0039] (B) Thermosetting resin mainly composed of a compound containing dihydrobenzoxazine

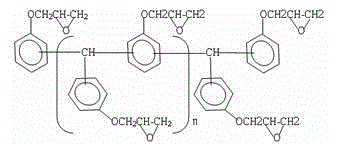

[0040] B1: Phenolphthalein type benzoxazine resin

[0041] B2: BPA type benzoxazine resin

[0042] (C) Phenolic resin

[0043] C1: Phosphorus-containing phenolic resin

[0044] C2: Novolac resin

[0045] (D) Accelerator

[0046] D: Diethyltetramethylimidazole

[0047] (E) Coupling agent

[0048] E: Silane coupling agent

[0049] (F) Inorganic filler

[0050] F1: fused silica

[0051] F2: spherical silica

[0052] Dissolve and mix the above resins according to the proportions in Table 1, then soak and coat on the reinforcing material glass fiber cloth, bake in an oven at 171°C for 3-5min to obtain a prepreg, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com