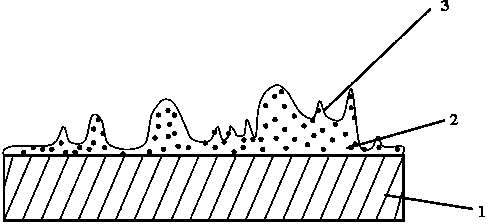

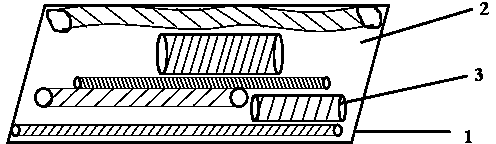

Hardening film for in-mold decoration

A technology of hardened film and hardened coating, applied in special decorative structures, decorative arts, polyurea/polyurethane coatings, etc. Injuries and other problems can be avoided to avoid environmental pollution and damage to operators, solve glare pollution, and improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] To 20.0 parts by weight of six-functionality aliphatic urethane acrylate prepolymer (Changxing Chemical Materials Co., Ltd., trade name: 6147, functionality: 6), 30.0 parts by weight of hyperbranched polyester acrylic resin (Changxing Chemical Materials Co., Ltd., trade name Name: 6361-100), 30 parts by weight of bifunctional reactive monomer tripropylene glycol diacrylate TPGDA (manufactured by Changxing Chemical (Zhuhai) Industry Co., Ltd.) and 15 parts by weight of multifunctional reactive monomer trimethylolpropane triacrylate Add 3.0 parts of photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: 184) and 2.0 parts by weight of leveling agent BYK307 (manufactured by BYK) to TMPTA (manufactured by Changxing Chemical (Zhuhai) Industry Co., Ltd.), and stir The coating material is obtained uniformly.

[0041] Coat the coating solution on one side of an optical-grade polyethylene terephthalate film (manufactured by China Lucky Film Group Co., L...

Embodiment 2

[0043] 30.0 parts by weight of octafunctional aliphatic urethane acrylate prepolymer (produced by Changxing Chemical Materials Co., Ltd., trade name: DR-U095, functionality: 8), 15.0 parts by weight of hyperbranched polyester acrylic resin (Changxing Chemical Materials Co., Ltd. Company, trade name: 6363), 15.0 parts by weight of bifunctional reactive monomer neopentyl glycol diacrylate NPGDA (Beijing Dongfang Chemical Factory) and 30.0 parts by weight of multifunctional reactive monomer trimethylolpropane triacrylate TMPTA 6.0 parts of photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: 1137) and 4.0 parts by weight of leveling agent Levaslip410 (manufactured by Deqian Chemical Co., Ltd.) were stirred evenly to obtain a coating material.

[0044] Coat the coating solution on one side of an optical-grade polyethylene terephthalate film (manufactured by China Lucky Film Group Co., Ltd., trade name: PG42) with a thickness of 125 μm. The fabric surfac...

Embodiment 3

[0046] To 40.0 parts by weight of hexafunctional aliphatic urethane acrylate prepolymer (manufactured by Shenzhen Dinghao Photochemical Technology Co., Ltd., trade name: DH-608, functionality: 6), 30.0 parts by weight of hyperbranched polyester acrylic resin (Changxing Chemical Materials Co., Ltd., trade name: 6361-100), 5.0 parts by weight of bifunctional reactive monomer tripropylene glycol diacrylate TPGDA (manufactured by Changxing Chemical (Zhuhai) Industry Co., Ltd.) and 20.0 parts by weight of multifunctional reactive monomer pentaerythritol tri Add 4.0 parts of photoinitiator (manufactured by Tianjin Tianjiao Chemical Co., Ltd., trade name: 184) and 1.0 parts by weight of leveling agent BYK354 (manufactured by BYK) to acrylate PETA (manufactured by Beijing Yingli High-Tech Development Co., Ltd.), Stir evenly to obtain coating materials.

[0047] Coat the coating solution on one side of an optical-grade polyethylene terephthalate film (manufactured by China Lucky Film G...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com