Rice starch based biodegradable packaging film and preparation method thereof

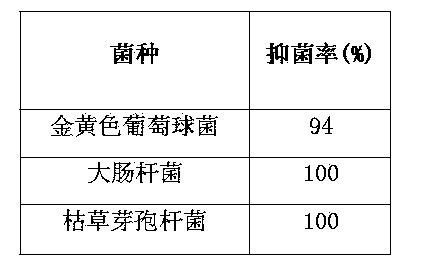

A rice starch, biodegradation technology, applied in the direction of biological packaging, sustainable packaging, packaging, etc., can solve the problems of resource waste, plastic film discarding, difficult to decompose and absorb, etc., and achieve good acid and alkali resistance and strong antibacterial property , high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The rice starch-based biodegradable packaging film of this embodiment is made of the following raw materials in weight percentage: 35% rice starch, 0.03% α-amylase, 10% chitosan, 4% sodium benzoate, and 2.95% potassium sorbate , 6% propionic anhydride, 20% polyvinyl alcohol (PVA), 0.02% glutaraldehyde, 2% ethylene glycol, 20% distilled water, a total of 1Kg of raw materials.

[0019] The preparation method of the rice starch-based biodegradable packaging film of the present embodiment comprises the following steps:

[0020] (1) Prepare α-amylase solution: Divide the prepared 200ml of distilled water into two parts, 100ml each, add 0.3g of α-amylase to 100ml of distilled water, stir well to obtain α-amylase solution; the other part is for later use ;

[0021] (2) Add the α-amylase solution obtained in step (1) into a beaker, preheat it to 52°C and place it in a 52°C constant temperature water bath, add rice starch while stirring; then place the beaker containing the mix...

Embodiment 2

[0025] The rice starch-based biodegradable packaging film of the present embodiment is made of the following raw materials in percentage by weight: 40% rice starch, 0.06% α-amylase, 8% chitosan, 4.9% sodium benzoate, 4% Potassium sorbate, 5% propionic anhydride, 17% PVA, 0.04% malondialdehyde, 1% glycerin, 20% distilled water. The preparation method of the rice starch-based biodegradable packaging film of this embodiment is the same as that of Embodiment 1.

Embodiment 3

[0027] The rice starch-based biodegradable packaging film of the present embodiment is made of the following raw materials in percentage by weight: 30% rice starch, 0.06% α-amylase, 8% chitosan, 5.9% sodium benzoate, 3% Potassium sorbate, 5% propionic anhydride, 22% PVA, 0.04% glyoxal, 1% polyethylene glycol, 25% distilled water. The preparation method of the rice starch-based biodegradable packaging film of this embodiment is the same as that of Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com