Waterproof acid-proof paint as well as preparation method and application thereof

An acid-resistant coating and acrylic resin technology, applied in the field of coatings, can solve the problems of accelerated aging and failure of concrete, no elasticity of the surface coating, affecting the protection of the coating on the concrete, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned two-component waterproof and acid-resistant coating, including the following steps:

[0053] S01. According to the formula of the above-mentioned two-component waterproof and acid-resistant coating, weigh the components in component A and component B respectively;

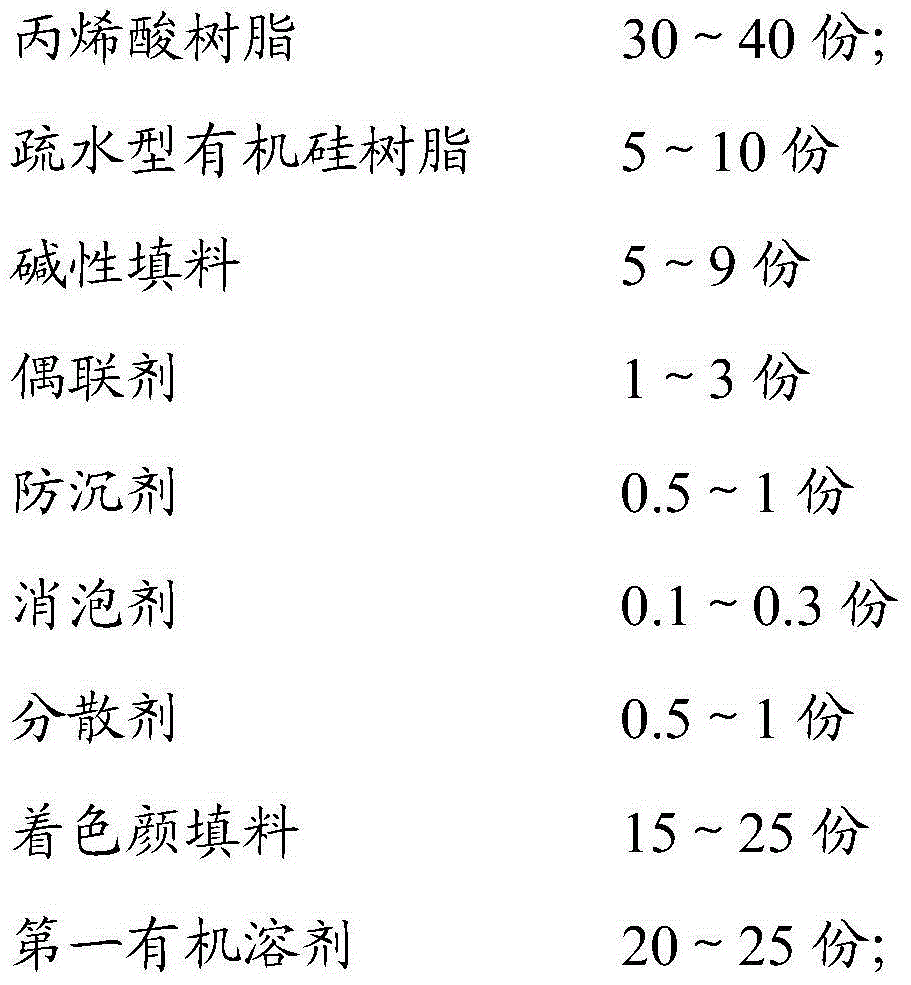

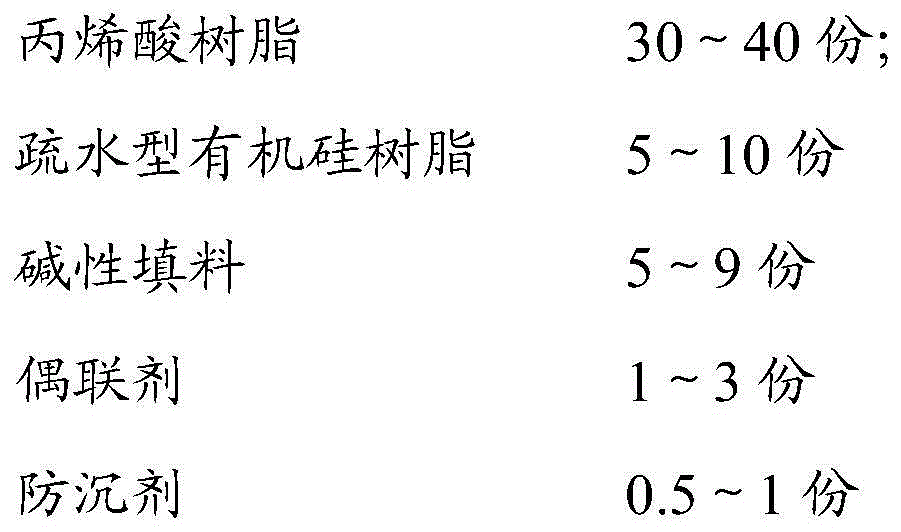

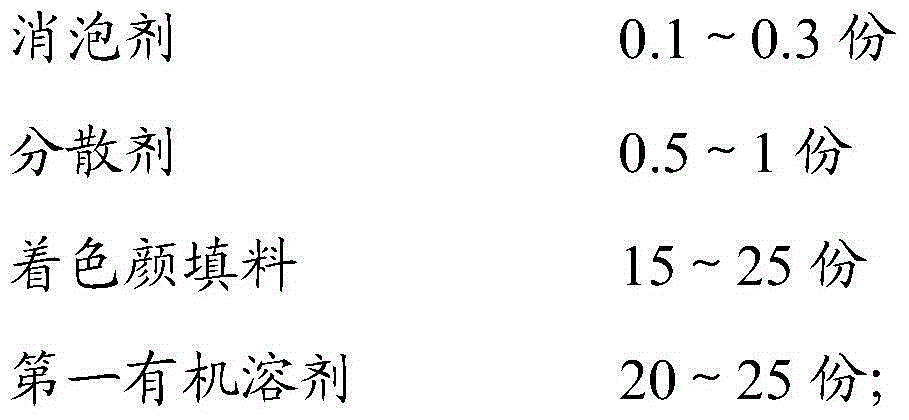

[0054] S02. First mix the above-mentioned acrylic resin, hydrophobic silicone resin and the first organic solvent, add the above-mentioned coupling agent, anti-sedimentation agent, defoamer, and dispersant during stirring and mixing, and then add basic filler Continue to mix with colored pigments and fillers to obtain the above-mentioned component A;

[0055] S03. Stir and mix the above-mentioned polyurethane curing agent with the second organic solvent to obtain the above-mentioned component B;

[0056] S04. Pack components A and B separately to obtain a two-component waterproof and acid-resis...

Embodiment 1~2

[0063] The specific components by weight of each two-component waterproof and acid-resistant coating in Examples 1-2 are shown in Table 1 below, wherein the preparation methods of each two-component waterproof and acid-resistant coating in Examples 1-2 are the same, and all include the following steps:

[0064] S01. according to the formula of each two-component waterproof and acid-resistant coating of embodiment 1 and 2 in the following table 1, weigh the components of component A and component B respectively;

[0065] S02. First add the weighed acrylic resin, hydrophobic silicone resin, and the first organic solvent and stir at a medium speed. During the stirring process, add coupling agent, anti-settling agent, defoamer, and dispersant to disperse evenly. The dispersion time is about 10 minutes; then add wollastonite, barium sulfate, titanium dioxide and calcium oxide, disperse at high speed for about 20 minutes, and the dispersion line speed is 1400m / min; then reduce the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com