Trass volcanic ash erosion resistance multi-layer thermal barrier coating

A technology of thermal barrier coating and volcanic ash, which is applied in the direction of coating, metal material coating process, blade support components, etc., can solve the problem of accelerating the phase transition instability and sintering of YSZ coating, reducing the strain tolerance of coating, ceramics Coating peeling failure and other problems, to achieve the effect of improving service life and reliability, improving corrosion resistance and service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

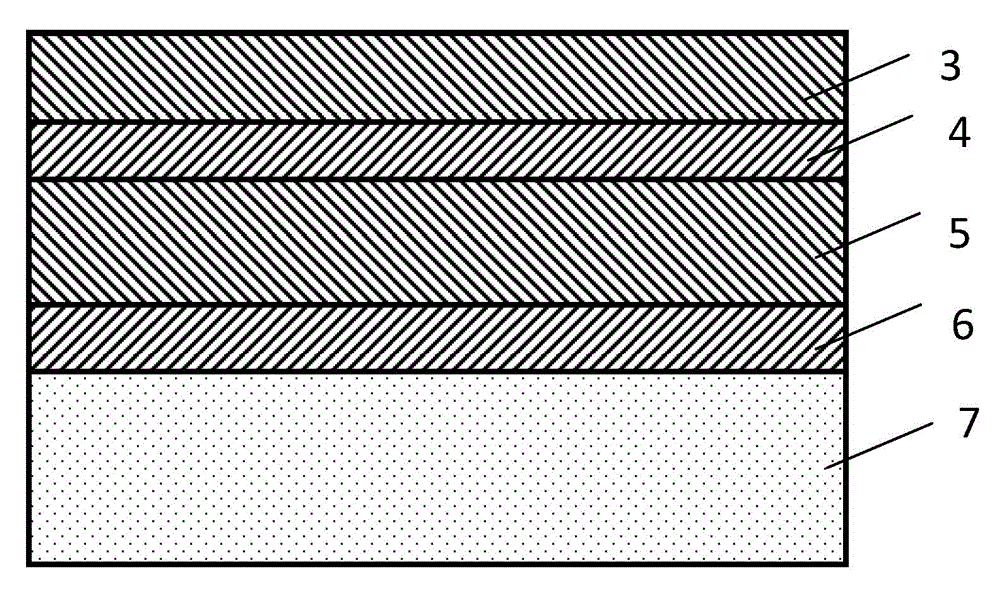

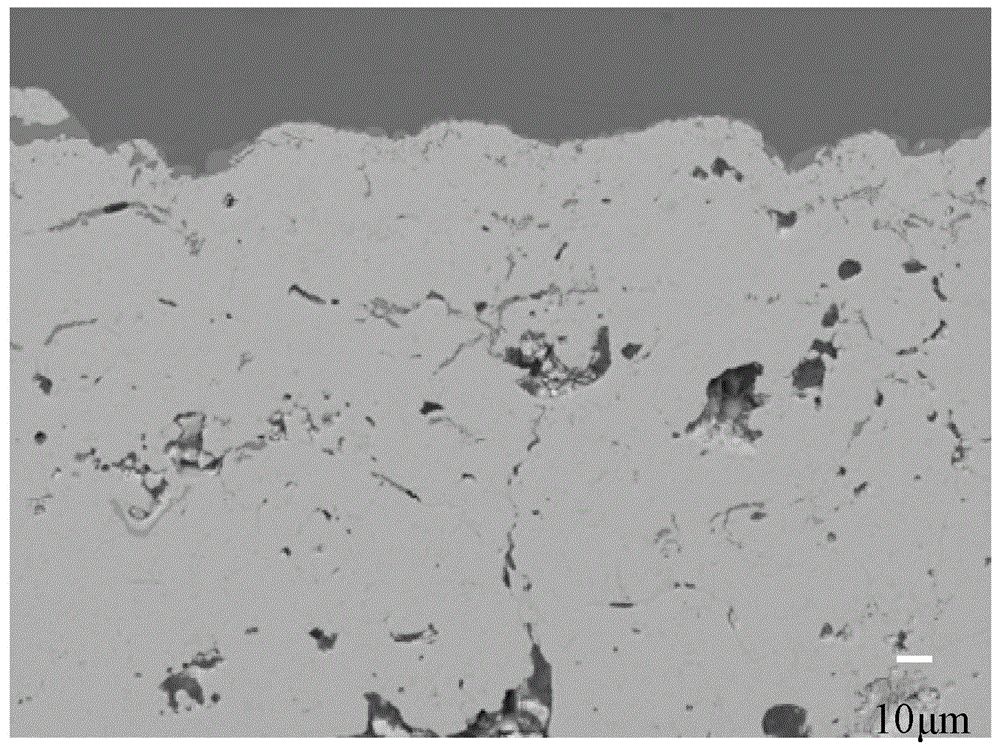

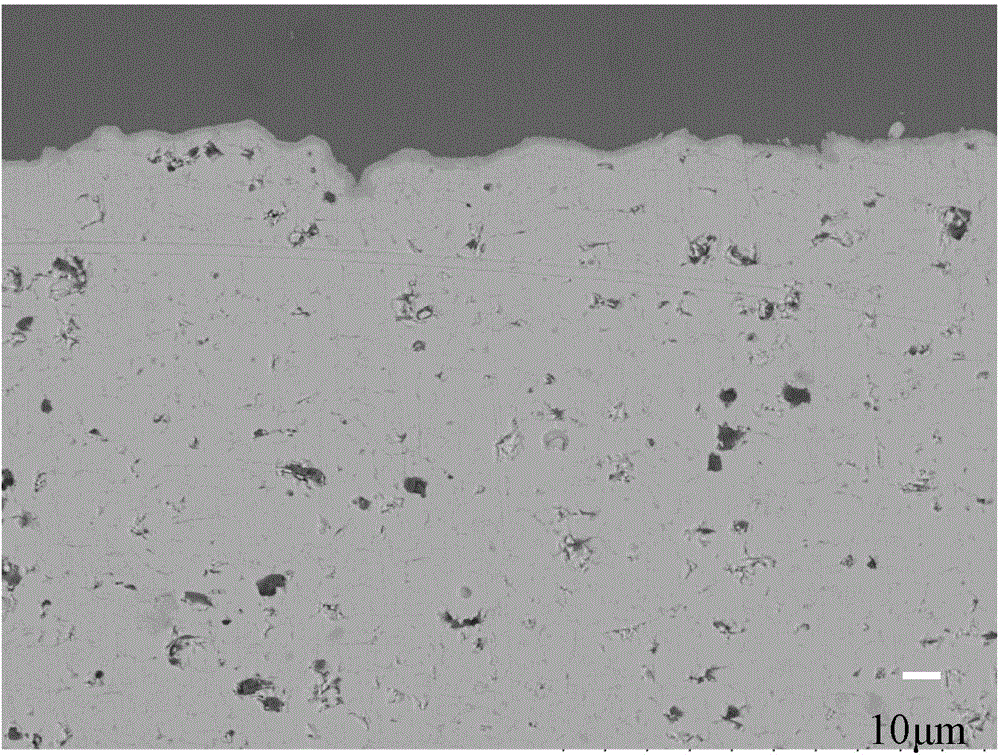

[0027] The present invention will be further described below with reference to the accompanying drawings and the following embodiments, and other details of the anti-volcanic ash erosion multilayer thermal barrier coating of the present invention and other accompanying purposes and advantages will be clarified. It should be understood that the drawings and the following embodiments are only used to illustrate the present invention rather than limit the present invention.

[0028] Generally, the thermal barrier coatings in aero-engines serve in high-temperature environments, and the volcanic ash floating in the atmosphere due to volcanic eruptions will be inhaled into the engine and deposited on the surface of the thermal barrier coatings, forming glass-phase pozzolanic deposits (CaO-MgO-Al 2 o 3 -SiO 2 ), the volcanic ash melts and infiltrates into the ceramic layer of the thermal barrier coating under high temperature conditions, reduces the strain tolerance of the coating, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com