A coal electrolysis liquefaction electrolysis device

一种电解装置、电解箱的技术,应用在煤液化领域,能够解决生产成本高、能耗大、生产工艺复杂等问题,达到生产设备成本低、生产工艺简单、原料消耗成本低的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

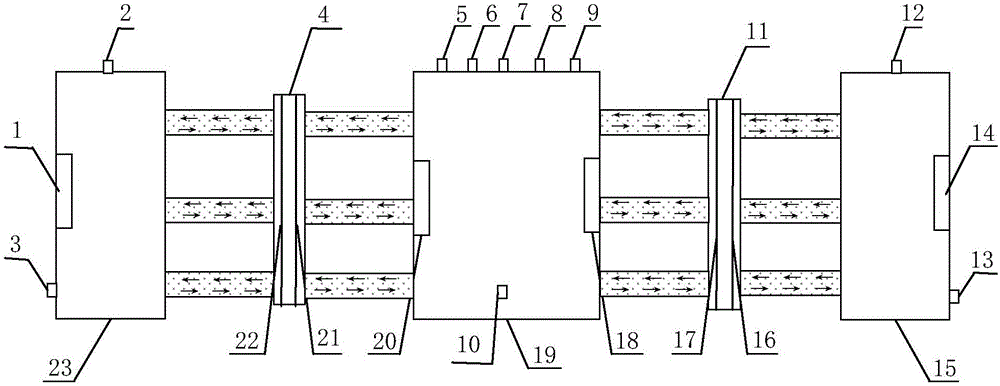

[0019] As shown in the accompanying drawings, a coal electrolysis liquefaction electrolysis device is composed of a negative electrode electrolytic box 19, two positive electrode electrolytic boxes 23, 15 and two mass transfer boxes 4, 11; the first positive electrode electrolytic box 23 is not One side of the graphite plate is communicated with the side of the first mass transfer box 4 provided with the polyethylene plate 22 through a conduction pipe, and the side of the first mass transfer box 4 provided with the polyvinyl chloride plate 21 is connected with the negative electrode electrolytic box 19 The side that is provided with nickel plate 20 communicates by conduction pipe, and the side that negative electrode electrolyzer 19 is provided with another piece of nickel plate 18 communicates with the side that second mass transfer box 11 is provided with polyvinyl chloride plate 17 by conduction pipe, The side of the second mass transfer box 11 provided with the polyethylene...

Embodiment 2

[0028] The coal electrolysis liquefaction electrolysis device in this embodiment is the same as the coal electrolysis liquefaction electrolysis device in Embodiment 1.

[0029] A coal electrification liquefaction electrolysis method using the coal electrification liquefaction electrolysis device in this embodiment, the steps are:

[0030] ①To prepare coal-water slurry, first crush the coal to a particle size of ≤1×10 -5 mm, the coal powder that is 61% by weight, the demineralized water that is 29% by weight and the sodium hydroxide that is 7% by weight are added into the container for beating and stirring for 6h, then add 3% lignosulfonic acid to disperse agent, continue beating for 4h;

[0031] ②Preparation of electrolyte Mix 12% by weight sulfuric acid and 88% by weight demineralized water to prepare electrolyte;

[0032] ③Feeding Add the coal-water slurry prepared in step ① into the negative electrode electrolytic box, add the electrolyte prepared in step ② into the two p...

Embodiment 3

[0037] The coal electrolysis liquefaction electrolysis device in this embodiment is the same as the coal electrolysis liquefaction electrolysis device in Embodiment 1.

[0038] A coal electrification liquefaction electrolysis method using the coal electrification liquefaction electrolysis device in this embodiment, the steps are:

[0039] ①To prepare coal-water slurry, first crush the coal to a particle size of ≤1×10 -5 mm, adding 60% coal powder by weight, 30% demineralized water and 8% sodium hydroxide into the container for beating and stirring for 5.5 hours, then adding 2% lignosulfonic acid Dispersant, continue beating for 3.5 hours;

[0040] ②Preparation of electrolyte: mix sulfuric acid with 11% by weight and demineralized water with 89% by weight to prepare electrolyte;

[0041] ③Feeding Add the coal-water slurry prepared in step ① into the negative electrode electrolytic box, add the electrolyte prepared in step ② into the two positive electrode electrolytic boxes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com