High-voltage large-capacity mixed tantalum capacitor bank integrated module

A technology of tantalum capacitors and tantalum electrolytic capacitors, which is applied in the direction of capacitors, electrolytic capacitors, capacitor parts, etc., can solve the problems of difficult growth of capacitor capacity and difficulty in meeting high energy density, and achieve low leakage current and good impedance frequency characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

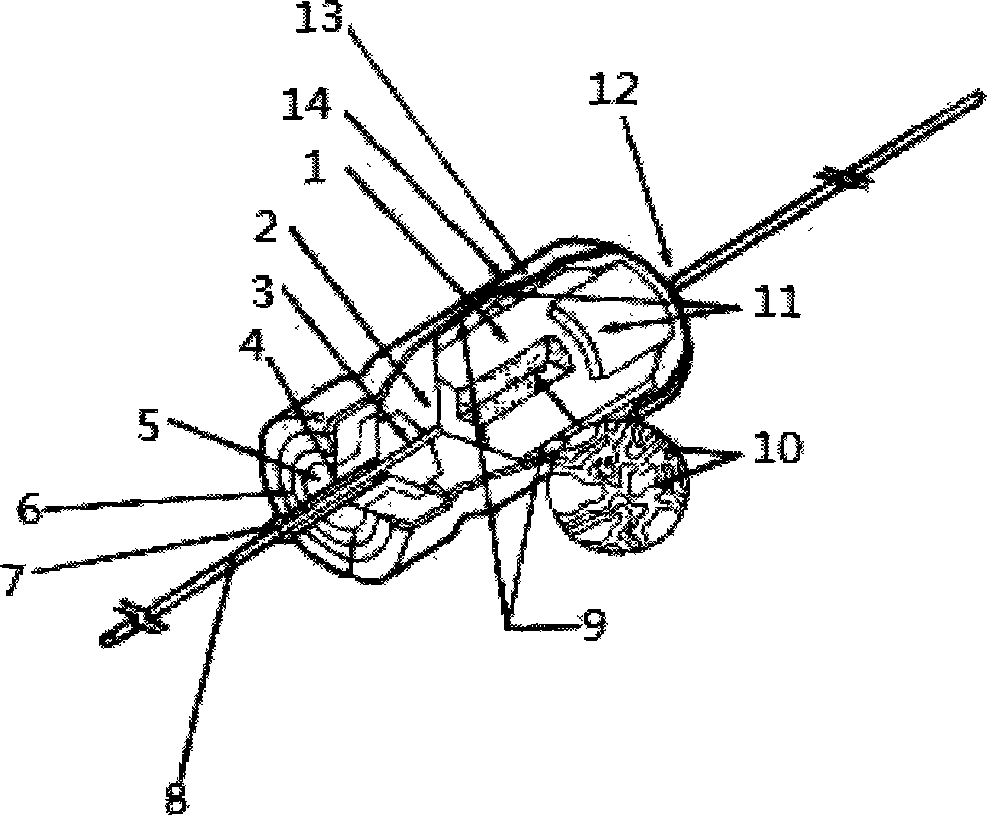

[0023] figure 1 is the internal structure diagram of the combined tantalum capacitor used in one embodiment of the present invention;

[0024] 1 Sintered tantalum block 2 PTFE shockproof gasket 3 Tantalum anode lead head 4 Tantalum tube

[0025] 5 Glass insulator and metal cover 6 Laser welding port 7 Anode lead with solder joint

[0026] 8 nickel lead wire (positive electrode) 9 gel sulfuric acid between tantalum block and shell 10 tantalum pentoxide

[0027] 11 Bracket PTFE shockproof gasket 12 Copper lead (negative pole) welded to the shell

[0028] 13 Ruthenium dioxide deposited on the inner wall of the shell 14 Full metal tantalum shell

[0029] According to the existing production process of the tantalum electrolytic capacitor CAK35, the invention improves the design of the 100V470μF tantalum electrolytic capacitor. First of all, high-puri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com