Skate liver oil and preparation method thereof

A technology for cod liver oil and cod liver, which is applied in the fields of edible oil/fat, food science, and application, can solve the problems of reduced extraction rate, a large amount of salt in by-products, and low demulsification effect, and achieves enhanced health care, low cost, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

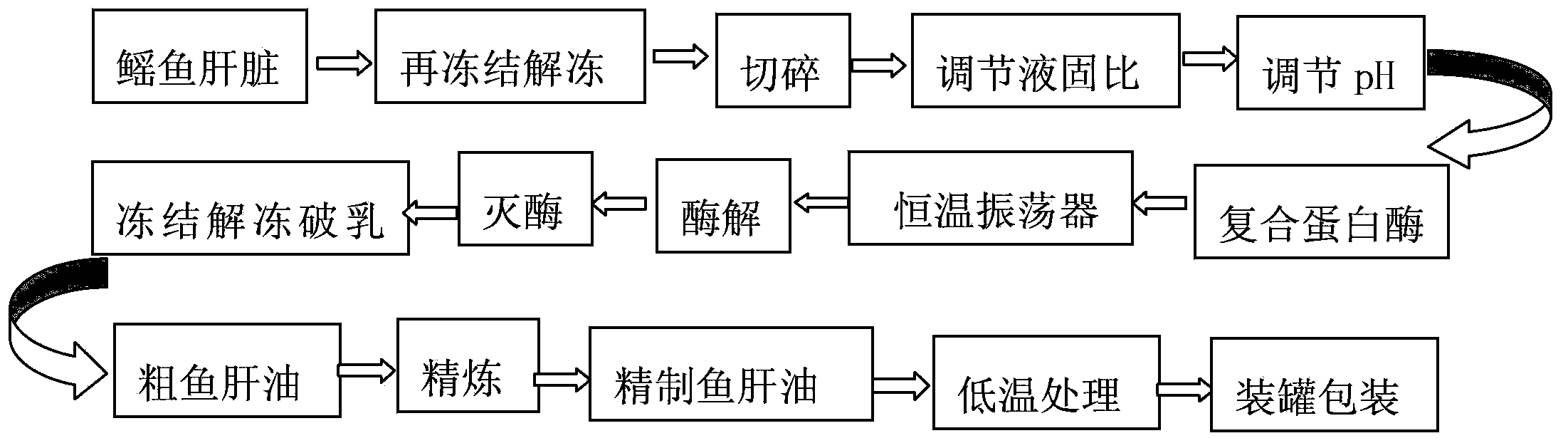

[0028] The preparation and production steps of the present invention are as follows:

[0029] 1) Storage of cod liver: the ray liver, a by-product of ray processing, is cleaned and stored in a freezer below -18°C.

[0030] 2) Pretreatment: thaw the cod liver and chop it; it can also be frozen and thawed and then chopped. The freezing temperature is below -18°C.

[0031] 3) Enzymatic hydrolysis: add a certain amount of distilled water to the hydrolysis pot to make the liquid-solid ratio (mass) 1.5:1, add hydrochloric acid to adjust the pH to 8, add cod liver 2% (mass) compound protease (composed of papain and Alkaline protease, the mass ratio is 2:3), sealed, placed in a constant temperature shaker (130r / min, 45°C), and enzymatically hydrolyzed for 3.5h.

[0032] 4) Enzyme inactivation: After enzymatic hydrolysis, add hydrochloric acid to adjust the pH to 3.5 to denature and inactivate the complex protease.

[0033]5) Centrifugal separation: Pour out the enzymatic hydrolysis ...

Embodiment 1

[0048] After thawing 5kg of ray liver (crude fat content: 1.45kg), put it in a freezer below -18°C to freeze again, then thaw and chop it, put it in a hydrolysis pot, add 5L of distilled water, and add hydrochloric acid to adjust the pH to 7.5 , add 75g of complex protease (composed of 18.75g of papain and 56.25g of alkaline protease), seal it, place it in a constant temperature oscillator, and enzymolyze it at a speed of 100r / min and a temperature of 40°C for 3h. After enzymatic hydrolysis, add hydrochloric acid to adjust the pH to 3 to denature and inactivate the compound protease, pour out the enzymatic hydrolysis solution, rinse the residue at the bottom of the hydrolysis pot with an appropriate amount of hot water for 2 times, incorporate the solution into it, and then place it in a low-speed large-capacity centrifuge , centrifuged while hot at a rotating speed of 4000r / min for 5min, and separated to obtain 1201g of crude cod liver oil in the upper layer. The middle layer...

Embodiment 2

[0050] After thawing 5kg of ray liver (crude fat content: 1.45kg), put it in a freezer below -18°C to freeze again, then thaw and chop it, put it in a hydrolysis pot, add 10L of distilled water, and add hydrochloric acid to adjust the pH to 8.5 , add 125g of complex protease (composed of 62.5g papain and 62.5g alkaline protease), seal it, place it in a constant temperature oscillator, and enzymolyze it at a speed of 150r / min and a temperature of 50°C for 4h. After enzymatic hydrolysis, add hydrochloric acid to adjust the pH to 3.5 to denature and inactivate the compound protease, pour out the enzymatic hydrolysis solution, rinse the residue at the bottom of the hydrolysis pot with an appropriate amount of hot water for 3 times, incorporate the solution into it, and then place it in a low-speed large-capacity centrifuge , centrifuged while hot at a rotating speed of 5000r / min for 15min, and separated to obtain 1243g of upper layer crude cod liver oil. The middle layer lipoprote...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com