Method for growing TiO2 nanowire thin film on surface of stainless steel wire screen

A surface growth, stainless steel technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of high equipment requirements and complexity, and achieve good repeatability, mild reaction, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) cleaning

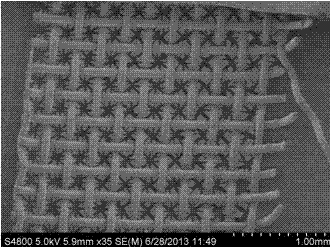

[0023] 2.5×2.5cm 2 The stainless steel wire mesh (100 mesh) was cleaned with detergent, then ultrasonically oscillated with absolute ethanol for 15 minutes, then deionized water for 10 minutes, and dried.

[0024] 2) Heat treatment of film drawing

[0025] Add tetrabutyl titanate, diethanolamine, deionized water and cetyltrimethylammonium bromide to ethanol to obtain a sol, the concentration of tetrabutyl titanate in the sol is 0.50 mol / liter, the concentration of diethanolamine 0.50 mol / liter, the concentration of deionized water is 0.50 mol / liter, the concentration of cetyltrimethylammonium bromide is 0.027 mol / liter, the stainless steel screen after cleaning is immersed in sol for 10 seconds with 6 Pulling at a speed of mm / s, and then holding at 450°C for 1 hour, the surface of the screen is covered with anatase TiO 2 TLC.

[0026] 3) Preparation of reaction solution

[0027] Add melamine and nitric acid to hydrogen peroxide with a mass con...

Embodiment 2

[0032] 1) same as embodiment 1 step 1);

[0033] 2) same as embodiment 1 step 2);

[0034] 3) Same as step 3 of embodiment 1);

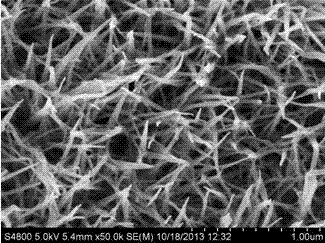

[0035] 4) The stainless steel wire mesh in step 2) was immersed in the reaction solution in step 3), and 0.25 g of titanium sponge was added as a titanium source, and reacted at 80° C. for 12 hours. Then keep it at 400°C for 1 hour to get TiO grown on the surface of the screen. 2 nanowire film.

Embodiment 3

[0037] 1) same as embodiment 1 step 1);

[0038] 2) same as embodiment 1 step 2);

[0039] 3) Same as step 3 of embodiment 1);

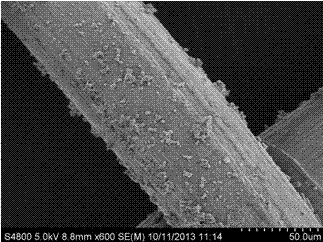

[0040] 4) Immerse the stainless steel wire mesh in step 2) in the reaction solution in step 3), and add 0.25 g of titanium sponge as a titanium source, react at 80 ° C for 24 hours, and then keep it at 550 ° C for 1 hour to obtain the growth on the wire. TiO on mesh surface 2 nanowire films.

[0041] image 3 The low-magnification scanning electron microscope photo shows that the surface of the stainless steel wire is uniformly covered with a nanowire film, and a small amount of powder on the stainless steel wire mesh is attached, which is the powder generated in the solution during the reaction and deposited on the stainless steel wire mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com