Cerium zirconium aluminum composite oxide oxygen storage material and preparation method thereof

A technology for composite oxides and oxygen storage materials, which is applied in the field of cerium-zirconium-aluminum composite oxide oxygen storage materials for automobile exhaust purification and its preparation, and can solve the problems of high temperature aging resistance, low specific surface area of products, and complicated preparation methods, etc. , to achieve the effects of good anti-aging performance, easy-to-obtain raw materials, and excellent oxygen storage and release performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 114.3 g of pseudo-boehmite with an alumina content of 70% to 216.0 g of deionized water, add 30.0 g of Tween 80, and heat and stir in a 90°C water bath for 1 h; 25.6 g of cerium nitrate and 30.3 g of zirconium nitrate were used 200g of deionized water was dissolved, 26.4g of hydrogen peroxide (15wt%) was added, fully oxidized, added to the above solution, and kept for 1h; ammonia water with a concentration of 25wt% was added, and the pH of the control end point was 10, and the temperature was kept for 1h. Then stop stirring, age at 90°C for 3h, filter to obtain a precipitate, wash with water until neutral, add 50g of polyethylene glycol 400 to the filter cake, beat and disperse, put it in a muffle furnace for 550°C roasting for 3h, the heating rate At 2°C / min, the cerium-zirconium-aluminum composite oxide oxygen storage material of the present invention is obtained.

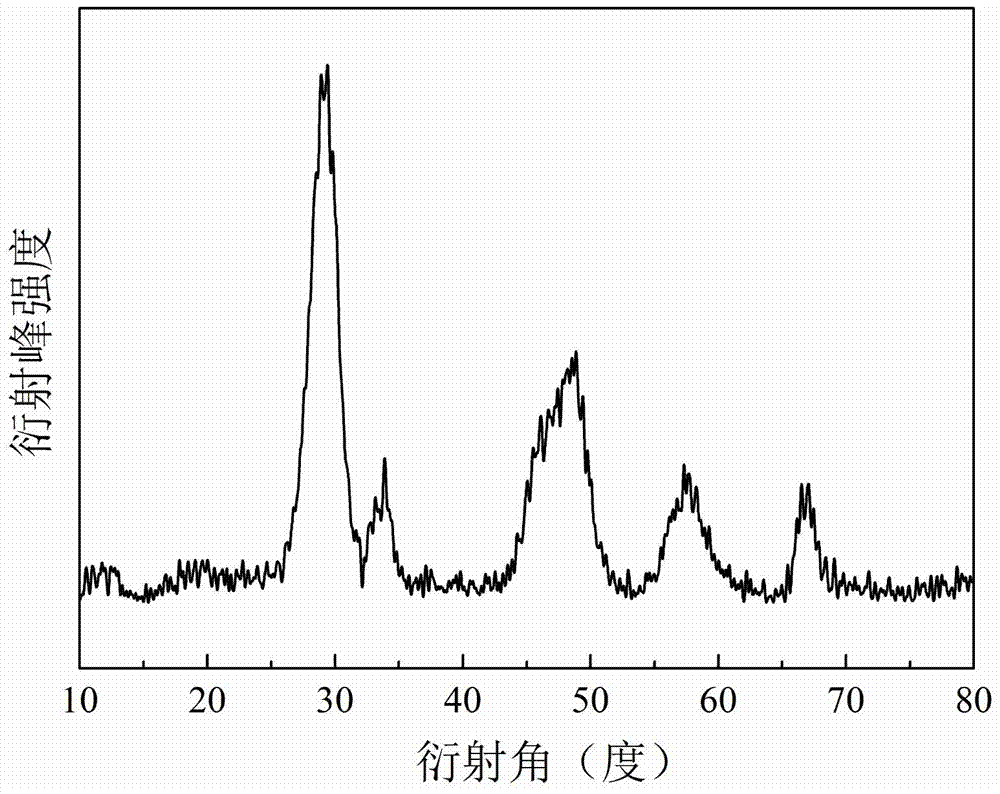

[0031] The composition of the material is 10% ceria, 10% zirconia, and 80% alumina. The fresh spec...

Embodiment 2

[0033] Add 71.4 g of pseudo-boehmite with an alumina content of 70% to 324.9 g of deionized water, add 10.0 g of sodium dodecyl sulfate, and heat and stir in a 50°C water bath for 3 hours; 76.9 g of cerium nitrate and 60.6 g of Zirconium nitrate was dissolved in 200g deionized water, 17.0g hydrogen peroxide (35wt%) was added, fully oxidized, added to the above solution, and kept for 3h; ammonia water with a concentration of 25wt% was added, and the pH of the control end point was 9, and the temperature was kept for 4h . Then stop stirring, age at 50°C for 4h, filter to obtain a precipitate, wash with water until neutral, add 50g of Tween 80 to the filter cake, beat and disperse, put it in a muffle furnace for 700°C roasting for 8h, and the heating rate is 10 ℃ / min to obtain the cerium-zirconium-aluminum composite oxide oxygen storage material of the present invention.

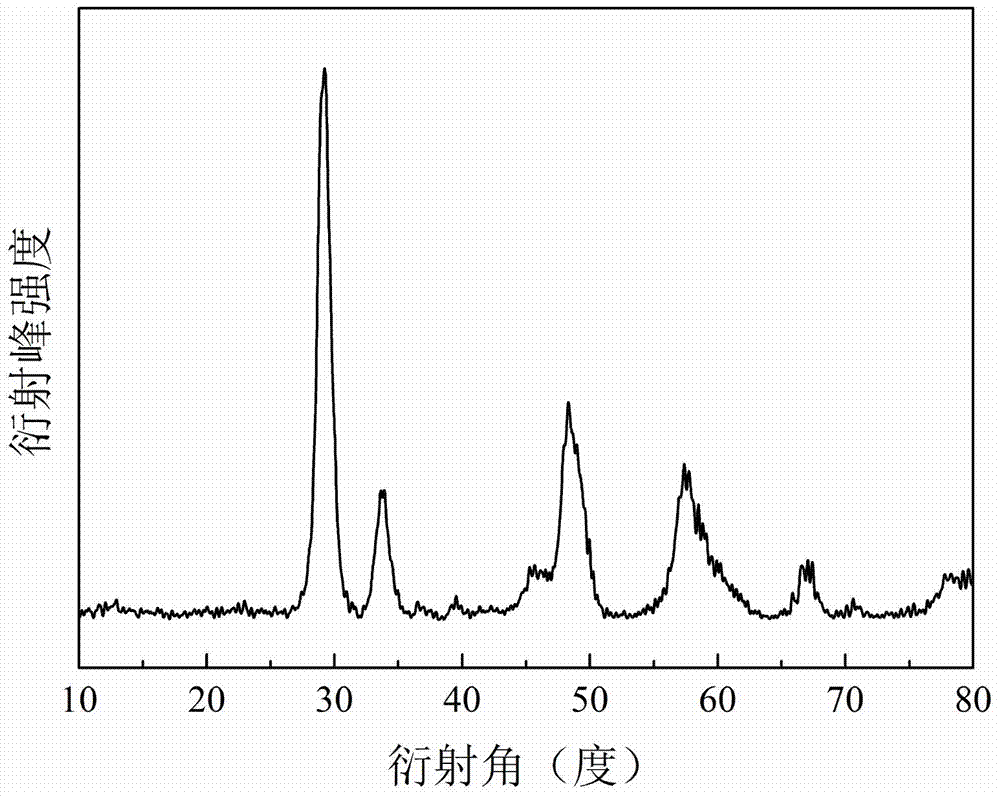

[0034] The composition of the material is 30% ceria, 20% zirconia, and 50% alumina. The fresh specific sur...

Embodiment 3

[0036] Add 85.7 g of pseudo-boehmite with an alumina content of 70% to 200 g of deionized water, add 20.0 g of cetyltrimethylammonium bromide, heat and stir in a water bath at 70 °C for 2 hours; add 59.0 g of cerium nitrate and 51.5g of zirconium nitrate were dissolved in 200g of deionized water, added with 18.2g of hydrogen peroxide (30wt%), fully oxidized and added to the above solution, kept for 2h; the concentration of 25wt% of ammonia water was added dropwise, and the pH of the control end point was 9.5 as Accurate, keep warm for 2h. Then stop stirring, 70 ℃ Aged for 2h, filtered to obtain the precipitate, washed with water until neutral, added 80g ethylene glycol butyl ether to the filter cake, beaten and dispersed, placed in a muffle furnace and calcined at 600°C for 4h, the heating rate was 5°C / min, The cerium-zirconium-aluminum composite oxide oxygen storage material of the present invention is obtained.

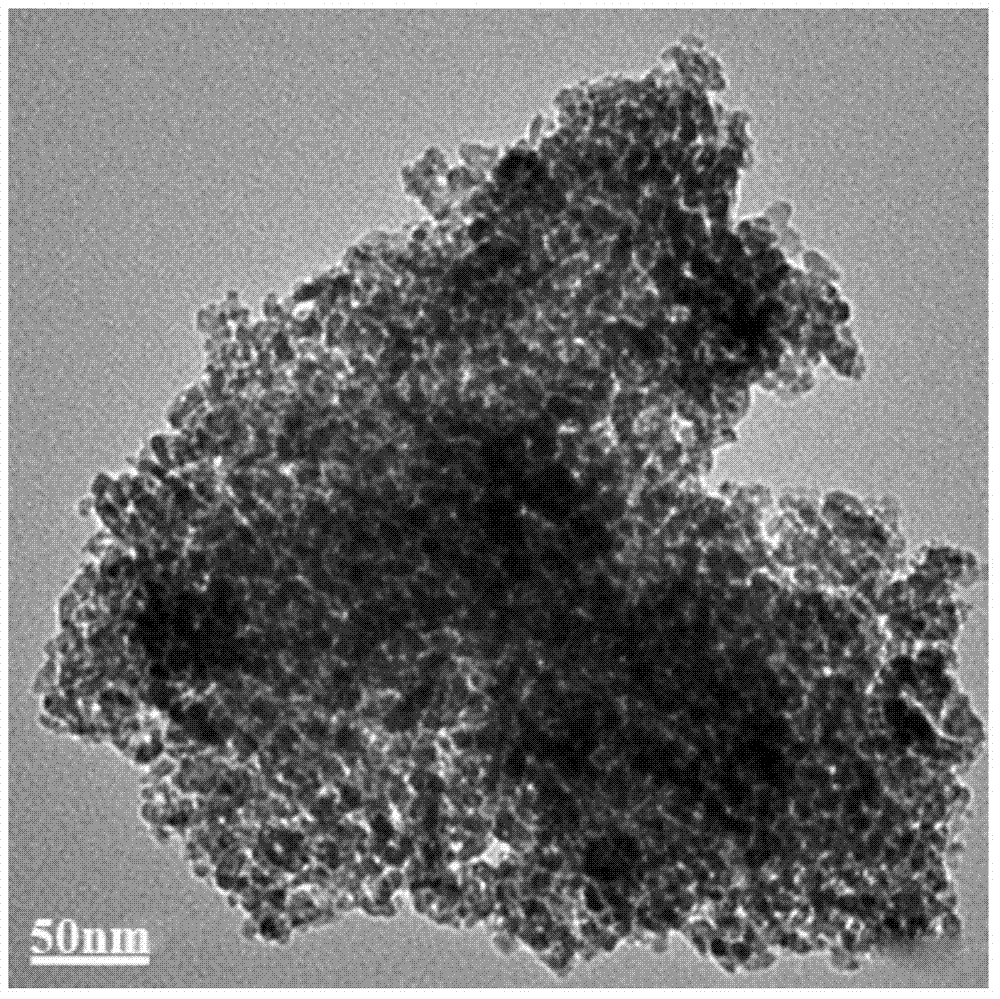

[0037] The composition of the material is 23% ceria, 17% zir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com