Biochemical treatment device and method for wastewater generated in production of polyester resin

A biochemical treatment device and technology for producing wastewater, which are applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of high operating cost of Fenton oxidation, high energy consumption of ozone oxidation technology, The problems of high investment and operating costs can achieve the effect of good microbial film hanging effect, enhanced mud-water contact effect, and large water quality fluctuation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

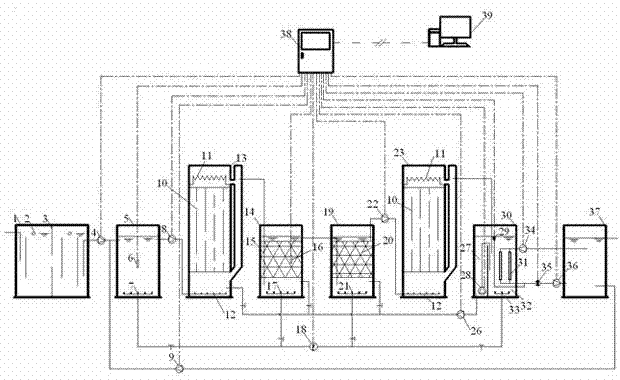

[0033] Take the pilot project of production wastewater treatment of a polyester resin powder coating manufacturer as an example, the scale of wastewater treatment is 1m 3 / sky. The average COD of the polyester resin production wastewater cr It is 35000mg / L, up to 40000mg / L, B / C is 0.25, SS is 250mg / L, and the main components are alkyl cyclopentanecarboxylate, 5,5-dimethyl-1,3-di Oxane, 4,5,5-trimethyl-m-dioxane, 1,4-dioxane, phenol, aldehydes and other refractory organic compounds.

[0034] The polyester resin production wastewater treatment plant handles the above-mentioned wastewater through the following steps:

[0035] 1) The wastewater passes through the grease trap 1 to remove the suspended oily particles in the upper layer to reduce the impact on the subsequent reaction tank and microbial activity, and then it is lifted by the primary metering lift pump 4, and the reflux effluent of the return metering pump 9 is in the distribution tank 5 Mixing and homogenization ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com