A kind of meropenem crude drug, its preparation method and pharmaceutical composition comprising the same

A technology of meropenem and raw materials, applied in antibacterial drugs, organic chemistry, etc., can solve the problems of harmfulness to patients, uncertainty, and no mention of the "maximum impurity" content, etc., and achieve good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0084] Add 12 kg of crude meropenem to 120 kg of water, stir to form a suspension, raise the temperature of the material to 50°C to dissolve it, and then lower the temperature to 10°C.

[0085] Add 100 g of activated carbon for decolorization, and filter.

[0086] Add 480 L of crystallization solvent acetonitrile to the filtrate, and stir and grow the crystal for 2 hours after the addition is complete.

[0087] Filter, wash the crystals with acetonitrile, and dry to obtain 10.6 kg of the first refined meropenem.

[0088] The quality of the first refined meropenem: the total amount of impurities is 0.75%; the residual organic solvent is 0.23%.

Embodiment 2

[0090] Add 10 kg of the first refined meropenem product prepared in Example 1 into 150 kg of water, stir, use a heat exchanger to raise the temperature of the feed solution to 50°C, then cool it down to 0°C, and grow the crystal with stirring for 15 hours.

[0091] Filter, wash the crystals with acetonitrile, and dry to obtain 8.1 kg of high-purity meropenem bulk drug.

[0092] Among them, the content of meropenem is 99.6% (calculated as anhydrous matter); impurity A in related substances is 0.04%; impurity B is 0.03%; any unknown single impurity is 0.01%; the sum of other impurities except A and B is 0.02% ; Acetone residue is 100ppm, and acetonitrile is not detected.

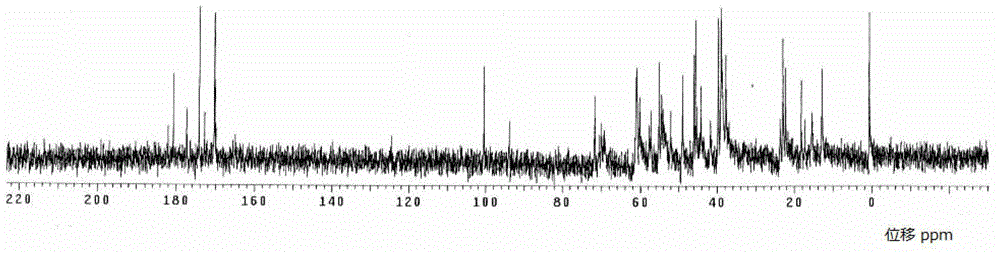

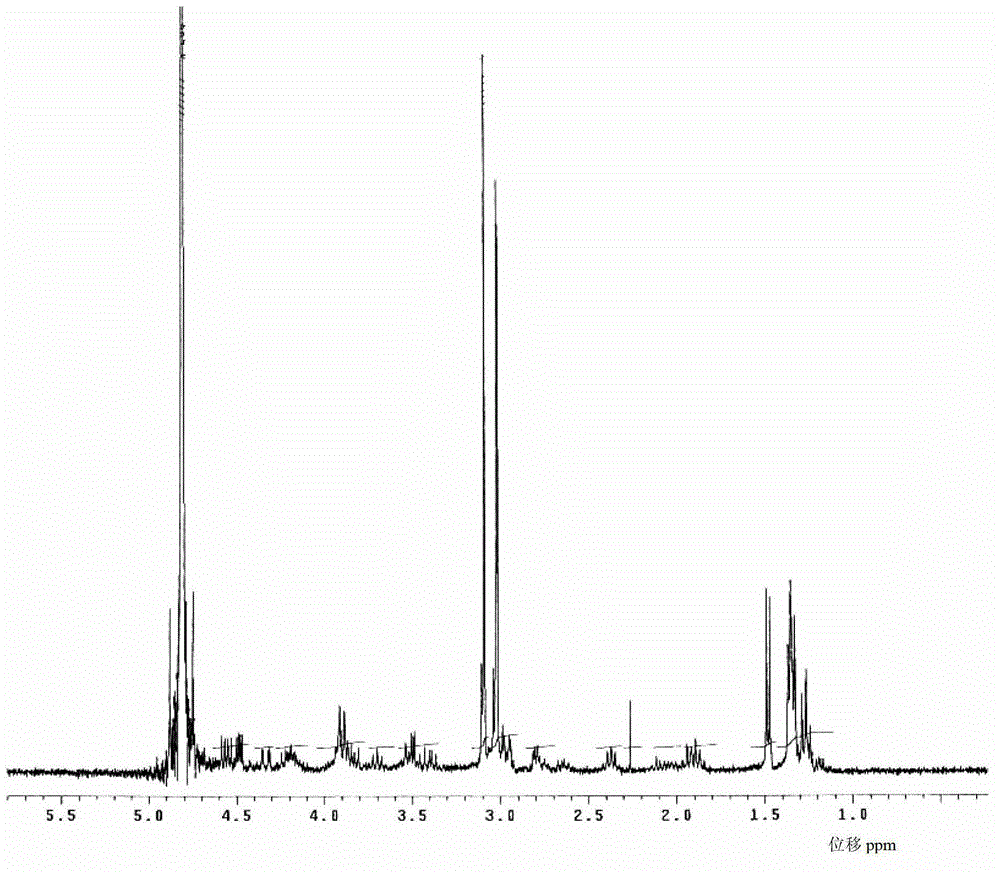

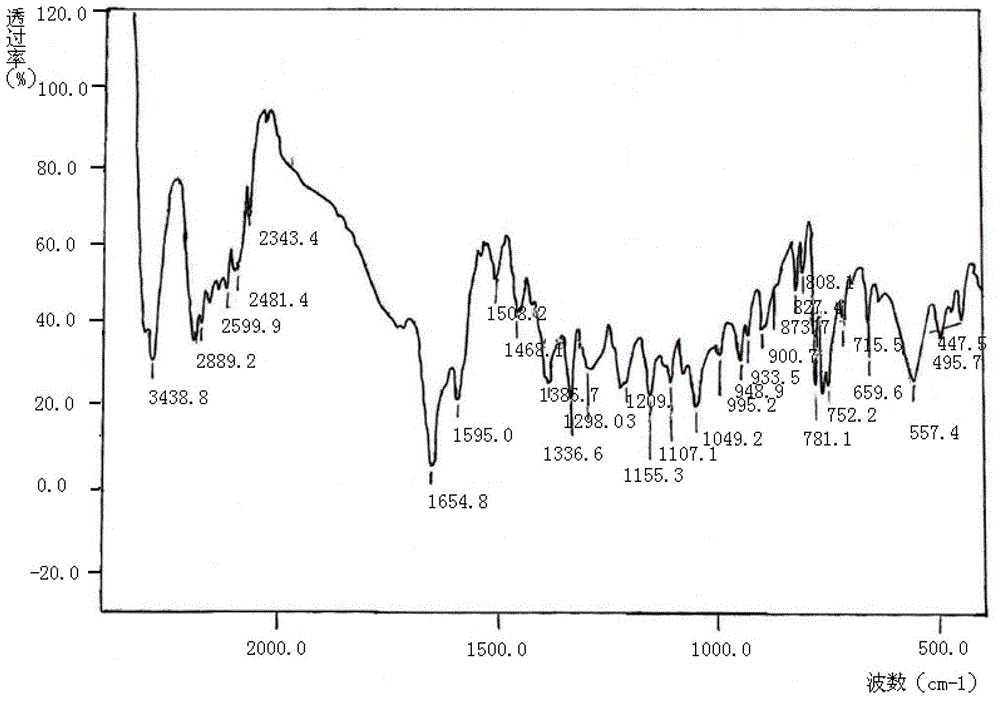

[0093] 1. Determination of the structure of meropenem:

[0094] The test results of the physical properties of the meropenem raw material are as follows:

[0095] Elemental Analysis: C 17 h 25 N 3 o 5 S·3H 2 o

[0096] Calculated: C, 46.67%; H, 7.14%; N, 9.60%; S, 7.33%;

[0097] Found: C, 46.46%; H, ...

Embodiment 3

[0131] Add 12kg of crude meropenem to 180kg of water, stir to form a suspension, raise the temperature of the feed solution to 80°C to dissolve it, and then lower the temperature to 20°C.

[0132] Add 240g of activated carbon for decolorization, and filter.

[0133] Add 360 L of crystallization solvent acetone to the filtrate, and continue to stir and grow the crystal for 3 hours after the addition is complete.

[0134] Filter, wash the crystals with acetone, and dry to obtain 10.44 kg of the first refined meropenem.

[0135] The quality of the first refined meropenem: the total amount of impurities is 0.62%; the residual organic solvent is 0.25%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com