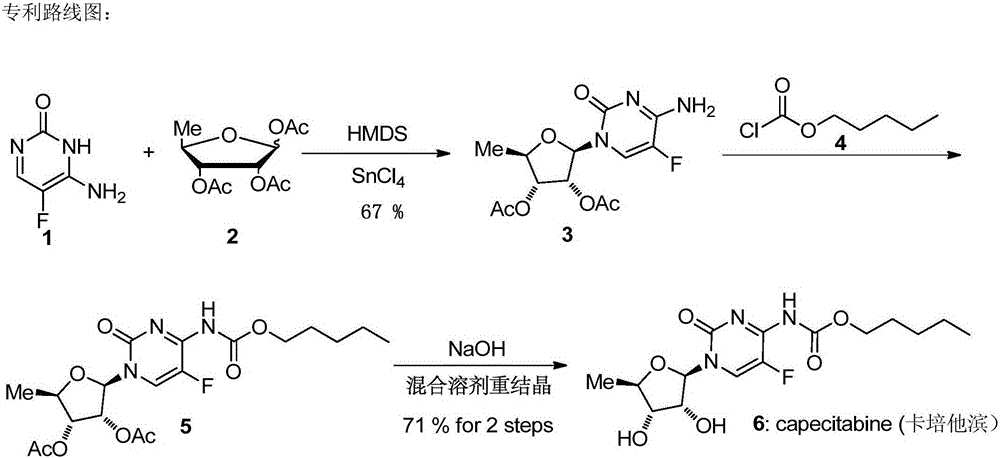

A kind of industrialized preparation method of capecitabine

A technology of capecitabine and reaction, which is applied in the field of preparation technology and product purification of anti-tumor drug capecitabine raw materials, can solve the problem of low purity of capecitabine raw materials, unfavorable large-scale production, small reaction scale, etc. problems, achieve the effect of reducing operational complexity, strict temperature control, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

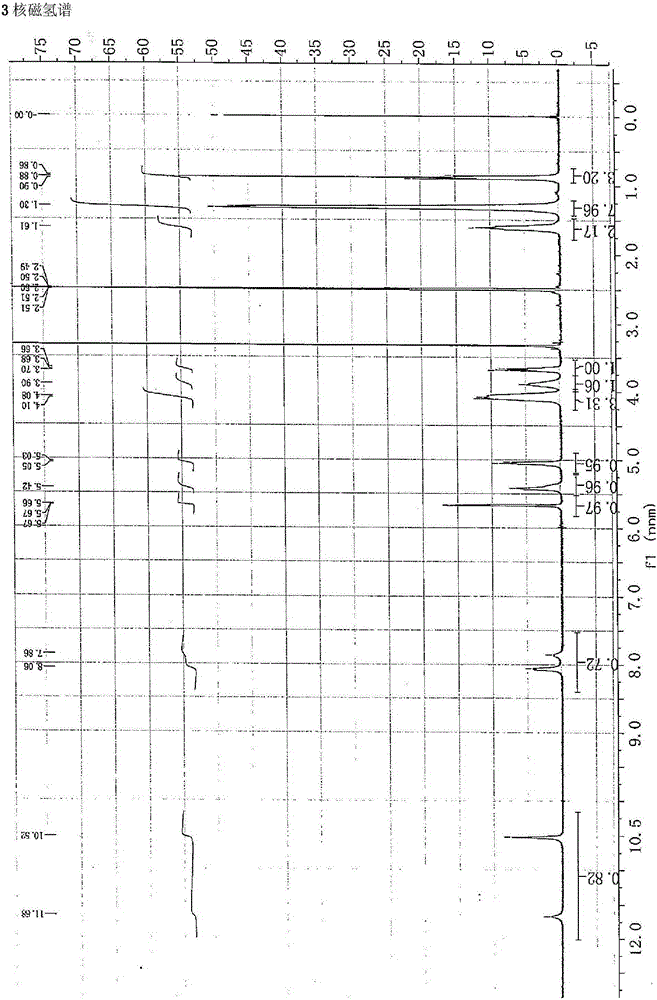

[0032] 14.2kg (110mol, 1.1eq) of 5-fluorocytosine 1 was added to a 50L reactor, then 29.8L of HMDS (143mol, 1.43eq) was added, and 20L of toluene was added, stirred and heated under reflux for 4h. The solvent was removed under reduced pressure (the bath temperature of the rotary evaporator was not higher than 70° C.) to obtain a white solid powder.

[0033] Suspend the above-mentioned white solid powder and 226kg (100mol, 1eq) of 5-deoxy-1,2,3-triacetyl deoxyribose in 100L of dichloromethane, and when the temperature in the reactor is lower than 2°C, use a constant pressure funnel to Add 15.2L (130mol, 1.3eq) SnCl dropwise 4 10L of dichloromethane solution (the internal temperature range of the dropwise addition process is 2°C to 8°C), slowly return to room temperature after dropping, and continue to stir and react at room temperature for 12h, then add 97.5kg of anhydrous Na to the system at low temperature 2 CO 3 (920mol, 9.2eq), then slowly add H 2 O26L (keep the internal...

Embodiment 2

[0037] The compound 2',3'-di-O-acetyl-5'-deoxy-5-fluorocytidine 319.76kg (60mol, 1eq) was dissolved in 49.4L dichloromethane (1kg:2.5L), and pyridine 9.66 L (120mol, 2eq), when the internal temperature of the reactor drops below -15°C, start to add 412.17L (84mol, 1.4eq) of n-amyl chloroformate dropwise, while keeping the internal temperature not higher than -5°C. After the dropwise addition, the temperature was naturally restored and the reaction was monitored by TLC until the reaction was complete. Add 20LH 2 O and 50L dichloromethane, after stirring for 10min, let stand to separate layers; separate the organic phase, wash with water (20L*2); the water phase is back-extracted with dichloromethane (50L*2); the organic phases are combined, anhydrous sulfuric acid Na-dried, and the solvent was removed under reduced pressure to obtain the yellow oily product 2',3'-di-O-acetyl-5'-deoxy-5-fluoro-N-[(pentyloxy)carbonyl]cytidine 5 (directly used in the next step).

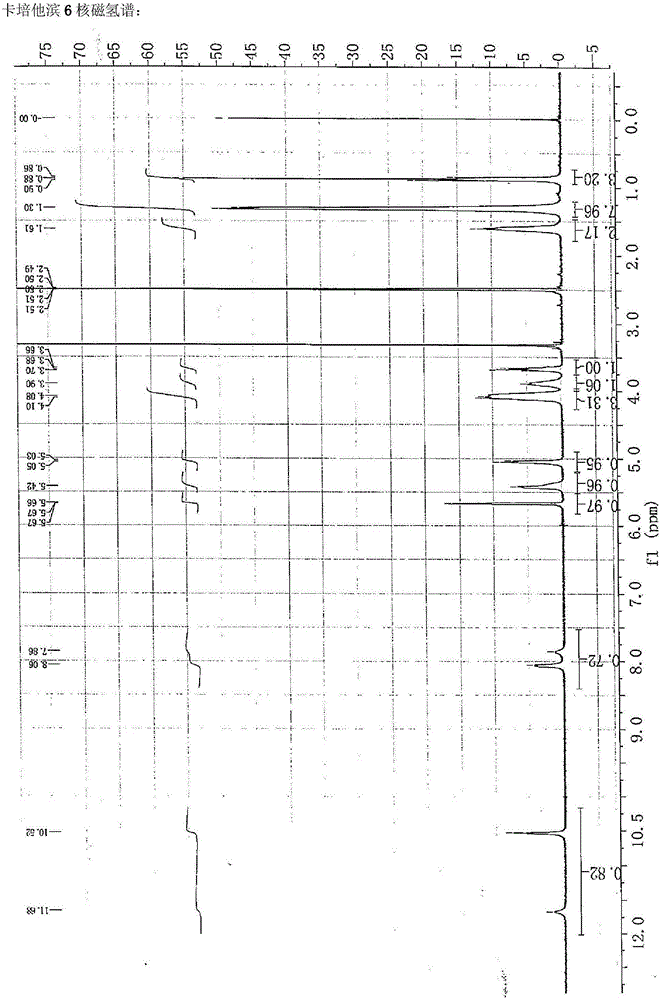

Embodiment 3

[0039] Dissolve the crude product 2',3'-di-O-acetyl-5'-deoxy-5-fluoro-N-[(pentyloxy)carbonyl]cytidine 5 in 28L of methanol from the previous step, and put it in the reaction kettle When the temperature drops below -10°C, start to drop 9.6kgNaOH (240mol, 4eq) in 24LH 2 O solution (10mol / L), keep the internal temperature not higher than -5°C during the period, continue to keep the low temperature (below -5°C) to react for 20min after dropping, then add about 20L of concentrated hydrochloric acid drop by drop, adjust the pH to 4-5, During this period, keep the internal temperature not higher than -5°C, add 10L of water and 100L of dichloromethane after the dripping, let stand to separate the layers, and separate the organic phase. The organic phase was washed with water (20L*2). The aqueous phase was back extracted with dichloromethane (50L*2). Combined organic phases, anhydrous Na 2 SO 4 Dry and concentrate under reduced pressure to give a slightly yellow oily substance. Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com