Method for extracting carrageenan

A carrageenan and gel technology, applied in the field of extracting carrageenan, can solve the problems of long consumption time, high cost, affecting product safety, etc., and achieve the effects of improving yield, high product strength, and shortening alkali treatment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

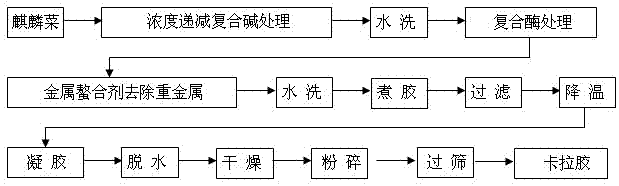

[0027] A method for extracting carrageenan, using Eucheuma as raw material, washing with water, treatment with compound alkali with decreasing concentration, compound enzyme treatment, metal chelating agent to remove heavy metals, boiling gum, coarse filtration, fine filtration, cooling, gelling, dehydration, cutting strips, dried, crushed, and sieved to obtain carrageenan.

[0028] A method for extracting carrageenan, comprising the steps of:

[0029] (1) Washing: Weigh 50g Eucheuma, wash with 1000g water;

[0030] (2) Compound alkali treatment with decreasing concentration: Add 1000g of compound solution with mass concentration of 5%NaOH, 5%KOH and 3%KCl to the Eucheuma obtained in step (1), treat at 75°C for 75min, wash with water Rinse until the pH value is 7; then add 1000 g of a compound solution with a mass concentration of 4% NaOH, 3% KOH and 3% KCl, treat at 75°C for 30 minutes, and rinse with water until the pH value is 7; finally add a mass concentration of 1000g ...

Embodiment 2

[0037] A method for extracting carrageenan, using Eucheuma as raw material, washing with water, treatment with compound alkali with decreasing concentration, compound enzyme treatment, metal chelating agent to remove heavy metals, boiling gum, coarse filtration, fine filtration, cooling, gelling, dehydration, cutting strips, dried, crushed, and sieved to obtain carrageenan.

[0038] A method for extracting carrageenan, comprising the steps of:

[0039] (1) Washing: Weigh 50g of Eucheuma, wash with 2000g of water;

[0040] (2) Treatment with compound alkali with decreasing concentration: Add 2000g of compound solution with a mass concentration of 5%NaOH, 5%KOH and 3%KCl to the Eucheuma obtained in step (1), treat at 75°C for 75min, wash with water After rinsing until the pH value is 7.5, pour out the treatment solution; then add 2000g of a compound solution with a mass concentration of 4%NaOH, 3%KOH and 3%KCl, treat at 75°C for 30min, and rinse with water until the pH value is...

Embodiment 3

[0047] A method for extracting carrageenan, using Eucheuma as raw material, washing with water, treatment with compound alkali with decreasing concentration, compound enzyme treatment, metal chelating agent to remove heavy metals, boiling gum, coarse filtration, fine filtration, cooling, gelling, dehydration, cutting strips, dried, crushed, and sieved to obtain carrageenan.

[0048] A method for extracting carrageenan, comprising the steps of:

[0049] (1) Washing: Weigh 50g of Eucheuma, wash with 1500g of water;

[0050] (2) Compound alkali treatment with decreasing concentration: Add 1500 g of compound solution with a mass concentration of 5% NaOH, 5% KOH and 3% KCl to the Eucheuma obtained in step (1), treat at 75°C for 75 minutes, wash with water After rinsing until the pH value is 8, pour out the treatment solution; then add 1500 g of a compound solution with a mass concentration of 4% NaOH, 3% KOH and 3% KCl, treat at 75°C for 30 minutes, and rinse with water until the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com