Method for producing isoprene by adopting cell fusion technology and fusant constructed by same

A technology of isoprene and microorganisms, which is applied in the field of isoprene production by cell fusion technology, can solve the problems of poor oil metabolism and low yield of isoprene, and achieve strong oil metabolism and convenient gene operation , the effect of clear genetic background

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

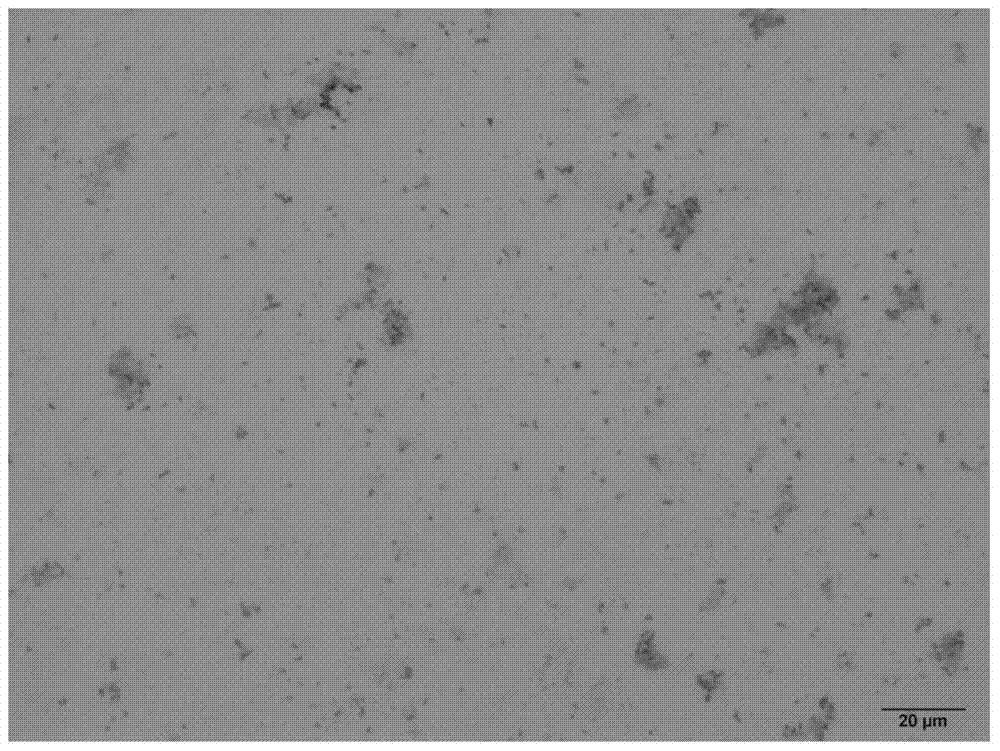

[0030] Alcaligenes eutropha with gentamicin resistance marker was inoculated in LB medium, cultured to the middle and late logarithmic growth period, the bacteria liquid was collected by centrifugation, and the bacteria were resuspended in 3 mL sucrose hypertonic solution Ⅰ (SMMP) , treated with lysozyme at a final concentration of 0.4g / L at 35°C for 8h. Protoplasts of Alcaligenes eutropha were prepared.

[0031]The medium SMMP used is 6g / L beef extract, 6g / L yeast extract, 20g / L peptone, 14g / L NaCl, 4g / L glucose, 14.7g / L K 2 HPO 4 , 5.4g / L KH 2 PO 4 , 170g / L sucrose, 2g / L maleic acid, 4g / L MgCl 2 6H 2 O, pH7.0.

[0032] The SMM used is 170g / L sucrose, 2g / L maleic acid, 4g / L MgCl 2 6H 2 O, pH7.0.

Embodiment 2

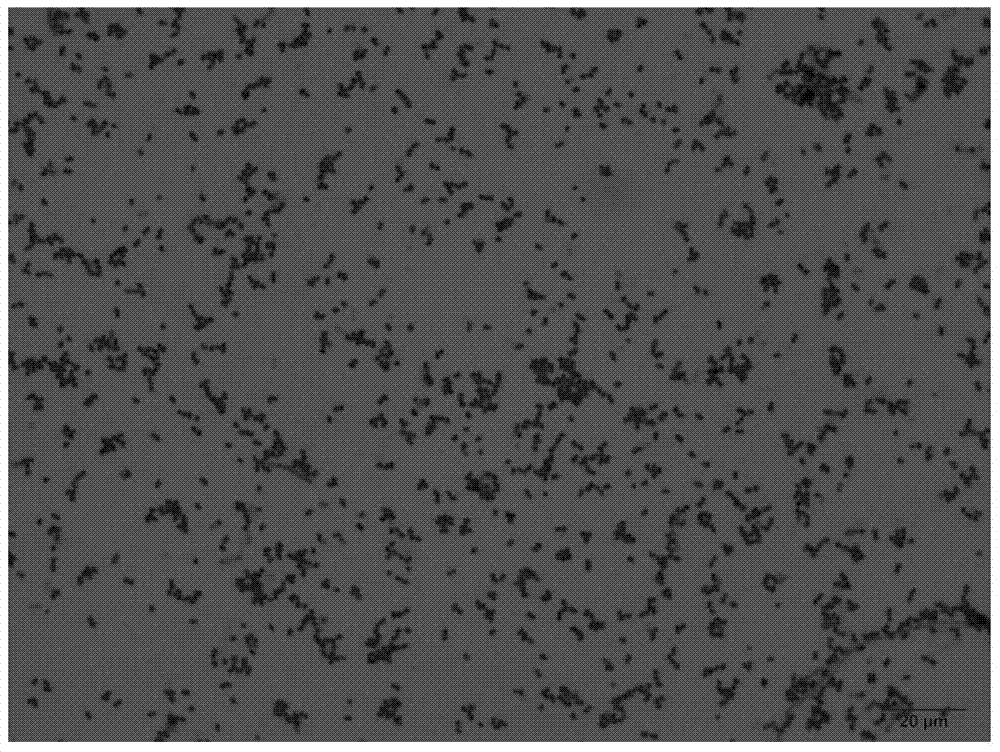

[0034] Inoculate engineered Escherichia coli (plasmid carrying isoprene synthesis pathway, see Yang, Plosone, 2012) in LB medium, culture until mid-to-late logarithmic growth, collect bacterial cells by centrifugation, and resuspend in 10 mL Sucrose hypertonic solution I (SMMP) was treated with lysozyme at a final concentration of 2g / L at 40°C for 16h. Preparation of E. coli protoplasts.

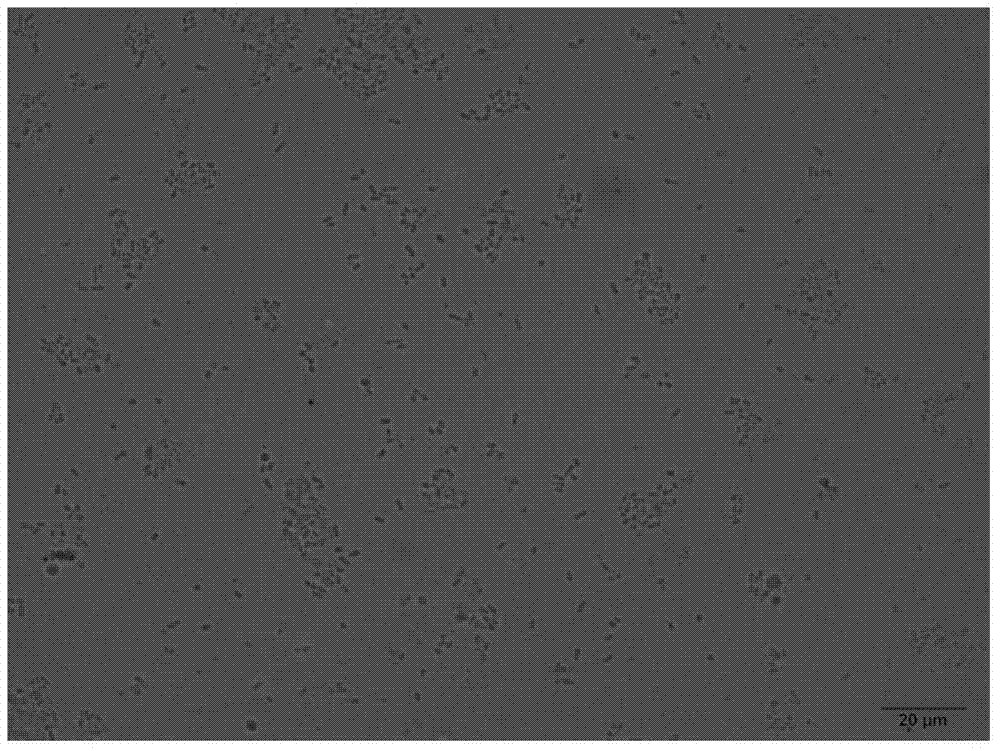

[0035] Then with the fusion and regeneration of the protoplasts of Alcaligenes eutropha obtained in Example 1. Add 14mL of 40% polyethylene glycol solution, mix well and incubate protoplasts at 30°C for 2 minutes, centrifuge at 3000r / min for 10 minutes, discard the supernatant, suspend fully with 2mL sucrose hypertonic solution II (SMM) solution, and then Spread in regeneration medium (CMR) containing 34mg / L chloramphenicol, 100mg / L penicillin and 10mg / L gentamicin, and culture at 30°C for 1-2 days. A total of 18 fusogens were obtained. Using lauric acid and peanut oil as carbon sources, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com