Novel method for high-efficiently producing astaxanthin by utilizing microalgae

An astaxanthin and microalgae technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of algal cell death, unretrieved, cell death, etc., to reduce production costs, improve Production efficiency, rapid accumulation of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

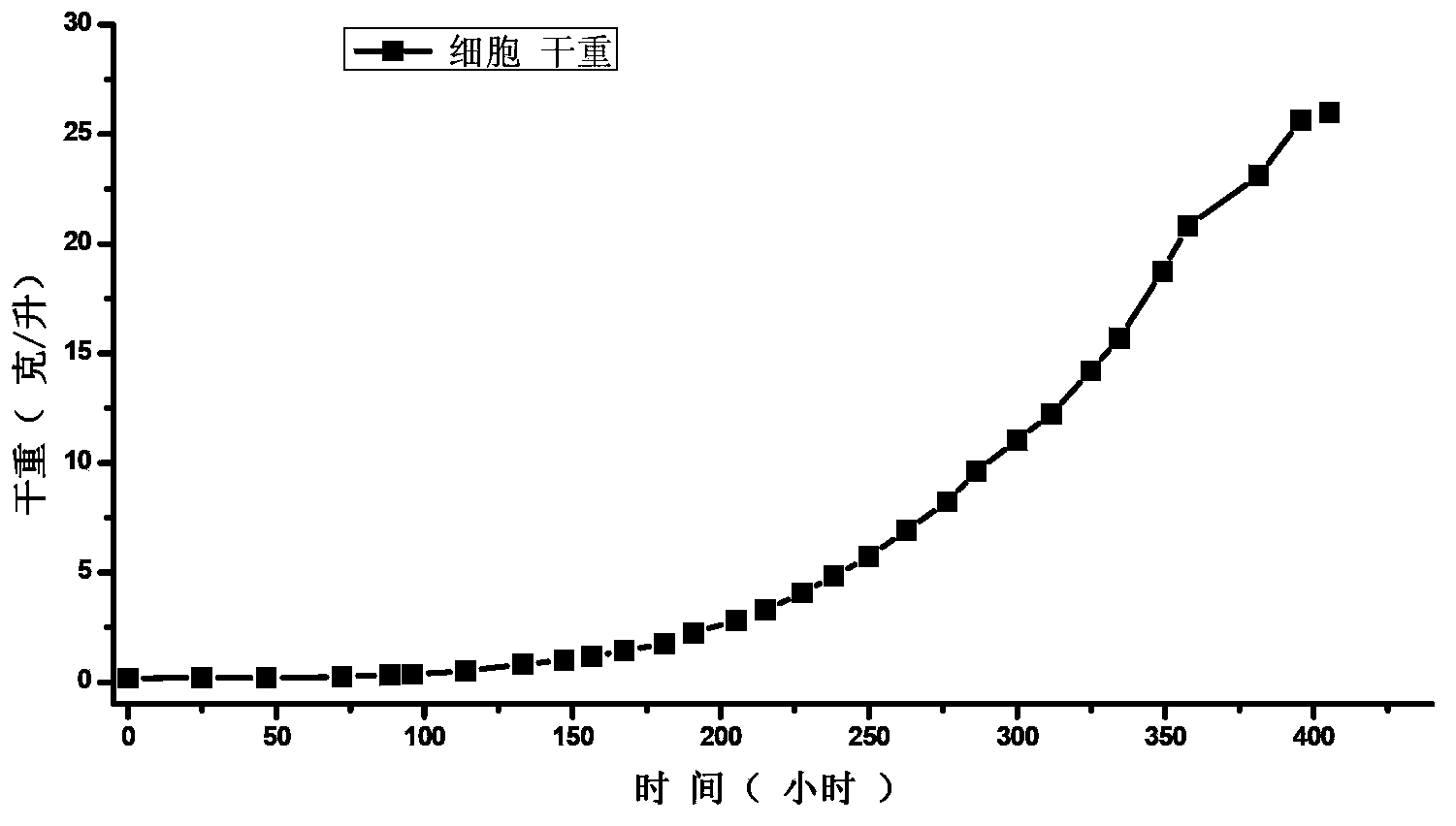

[0097] Add the following heterotrophic medium and water to 2.5L in a 5L bioreactor, then steam sterilize it, then insert Haematococcus pluvialis when the temperature drops to 25°C, and start heterotrophic culture.

[0098] Heterotrophic culture conditions: the temperature is 25±1°C, the air flow is 1vvm, the pH is not controlled in the early stage, and the dissolved oxygen is controlled above 10%.

[0099] After 140 hours of inoculation, the medium concentrate was added, and the pH was controlled at 7.5-8.0.

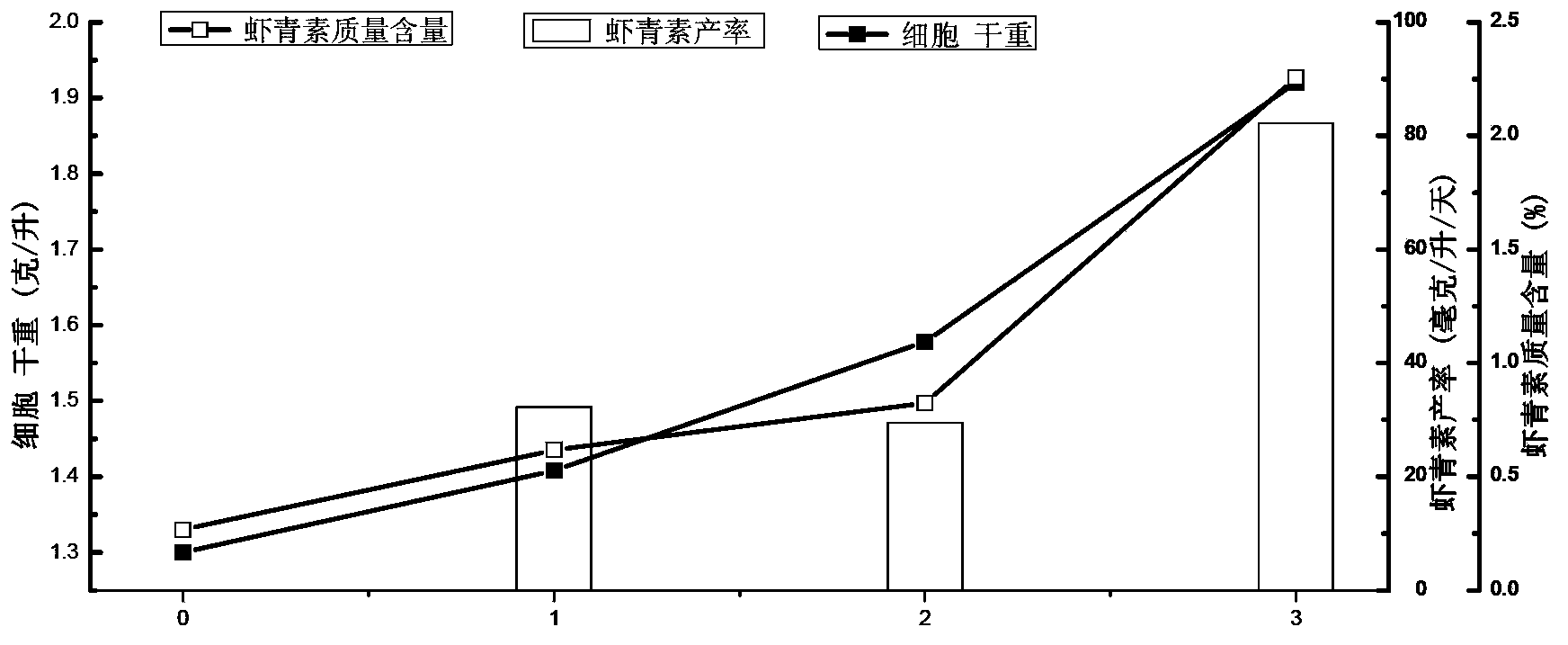

[0100] Put 8.5g / L of high-density algae liquid in the process of heterotrophic culture into 1L, dilute it to 1.3g / L with light-induced medium, add the above-mentioned light-induced medium, and transfer it to a 2L column photobioreactor Perform light-induced culture. Light-induced culture conditions: the temperature is maintained at 28-38°C, the air flow rate is 1vvm, natural light, and the light intensity on each side is about 75klx. After 3 days of light-induced cultu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com