Bismuth particle X-ray contrast agents

A particle and coating agent technology, applied in the preparation of X-ray contrast agents, bismuth organic compounds, applications, etc., can solve problems such as the difficulty of stabilizing water-based metal nanomaterials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

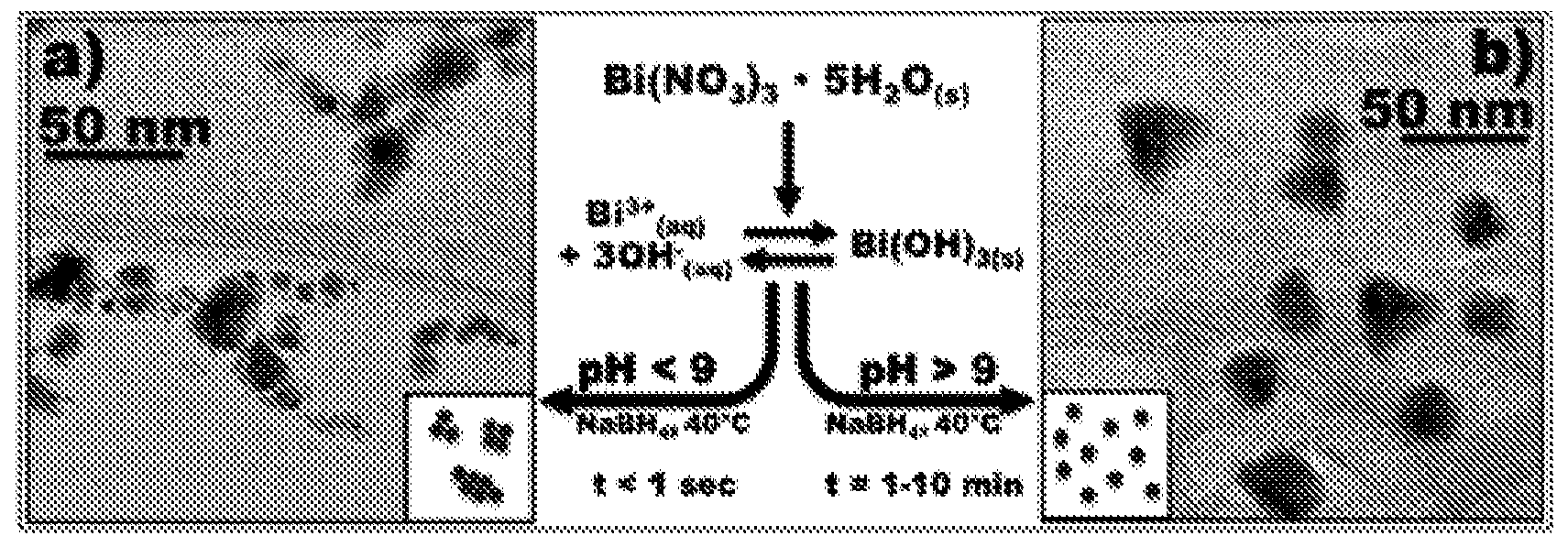

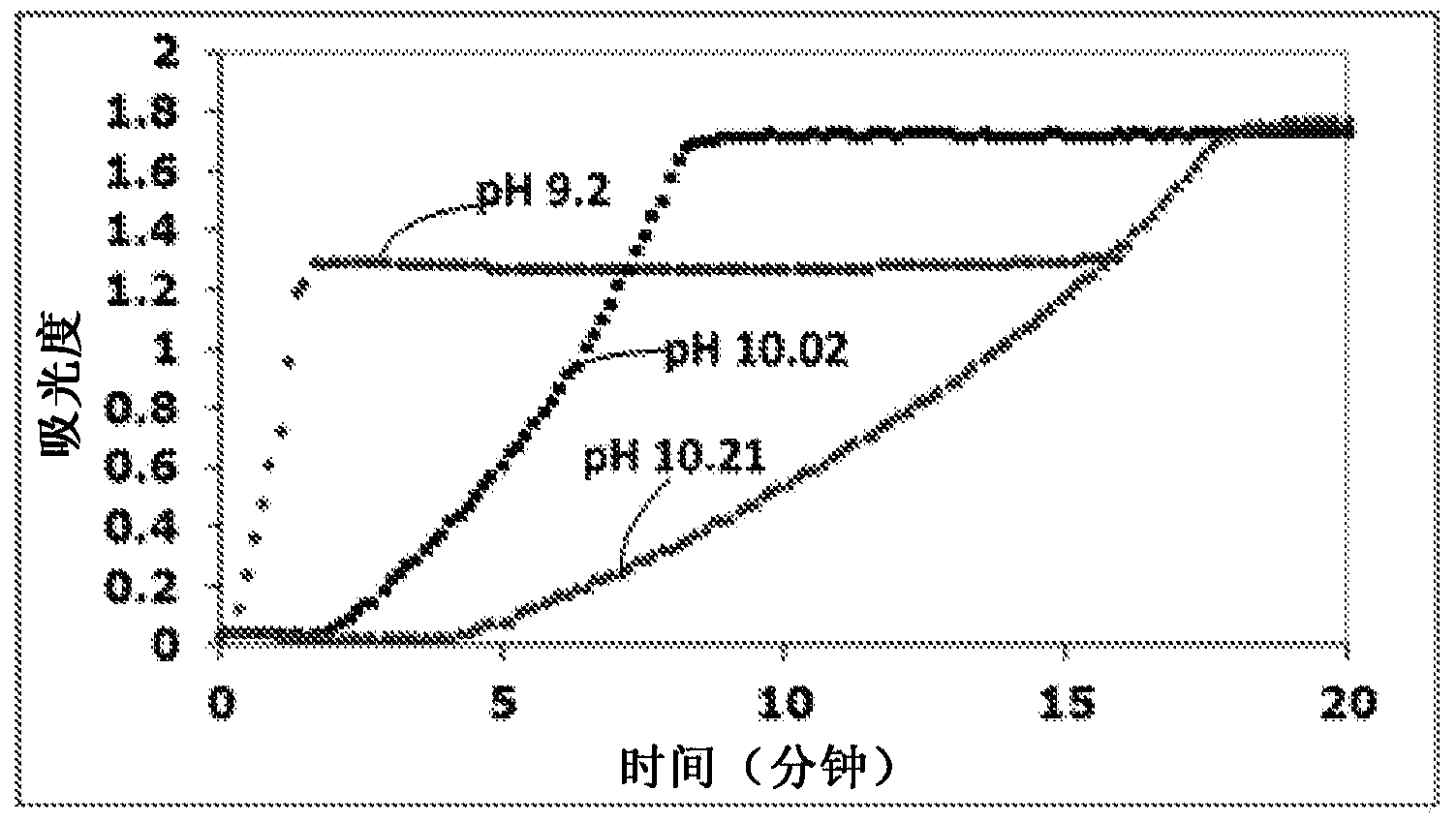

[0130] Synthesis and Properties of Bismuth Sugar Nanoparticles with Dextran / Water Coating

[0131] Reagents: bismuth nitrate pentahydrate (Acros organics98%), glycine (Acros, 99+% analytical grade), potassium hydroxide (reagent grade), dextran (Carbomer Inc., 75,000MW, clinical grade), sodium borohydride ( MP Biomedicals, 98-99%) and phosphoric acid (>85%, Sigma-Aldrich) were obtained commercially and were used as received without further purification. Use fresh electrophoretic pure H for all stock solutions 2 O (conductivity 18MΩ) preparation.

[0132] Synthesis: In a typical synthesis, 250 mg (0.52 mmol) Bi(NO 3 ) 3 ·5H 2 O suspended in 25 mL H 2 O middle. During the reaction, the temperature was kept constant at 40°C by submerging the reaction vessel in a temperature-controlled water bath. All reactions were performed using >800 rpm magnetic stirring. Add 10 mL of 2M glycine solution (20 mmol) and appropriate amount of 2M KOH to obtain the desired pH (eg about 12 mL...

Embodiment 2

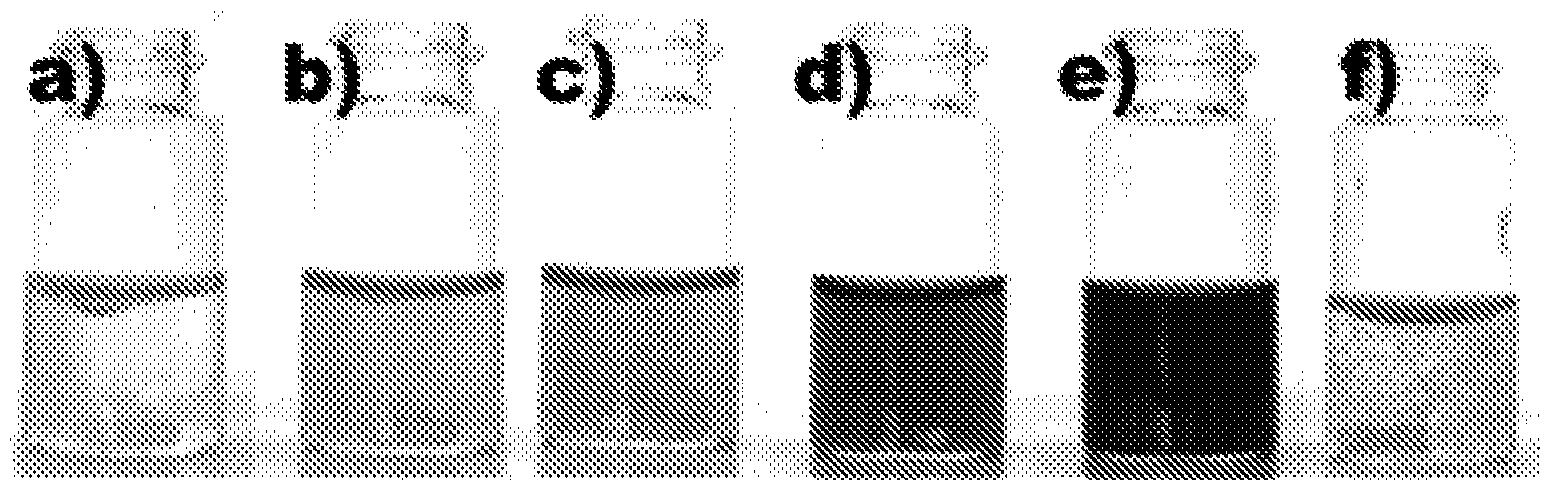

[0155] radiopaque thread

[0156] Reagents: 99.5% 100 mesh (approximately 150 μm particles) bismuth powder obtained from Acros Organics (#318091000), oleic acid was commercially available and used without modification. General Electric Premium Waterproof Clear Silicone (100% Silicone, #51220) was purchased from a building supply store and used as is.

[0157] Synthesis: Calculate the required amounts of silicone and bismuth powder (see Table 2). Bismuth powder was coated with hexane and then mixed with unpolymerized silicone using mechanical agitation and ultrasound. The volume of hexane was sufficient to just wet the bismuth powder without excess liquid hexane present. The cotton thread is then stirred in the mixture, removed, and dried at ambient temperature. The silicone polymerizes during drying, forming a coating of silicone-bismuth particles on the wire. The stirring and drying steps were repeated until most of the bismuth solution adhered to the wire.

[0158] Tabl...

Embodiment 3

[0164] Comparison of Alkanes and Alkenes as Coating Agents

[0165] Bismuth particles coated with pentane or 1-pentene were prepared by milling 5 g of elemental bismuth with tungsten carbide balls in a stainless steel mill in the presence of 10 mL of solvent for 20 minutes. The resulting powder was passed through a 45-μm sieve and hexane was added.

[0166] Figure 13 a-13b are SEM micrographs of 1-pentene-coated bismuth particles and pentane-coated bismuth particles, respectively. The results confirm that the olefinic capping agent provides superior colloidal stability with fewer aggregates than similar alkanes. Without being bound by a particular theory, it is believed that the mechanical force breaks up the bismuth powder particles, forming bismuth microparticles and nanoparticles, and temporarily creates a clean reactive surface by temporarily disabling metallic bonds, rendering the surface electrophilic. Therefore, alkenes may be more effective capping agents because t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com