Porosity measuring method and device of porous material

A technology for porous materials and porosity, which is applied in measuring devices, suspension and porous material analysis, permeability/surface area analysis, etc. It can solve the problem that there is no method for determining the porosity of hydrophilic porous materials, and the inability to accurately measure hydrophilic porous materials Porosity and other issues, to achieve the effect of cost reduction, simple, fast and convenient measurement method, and low test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

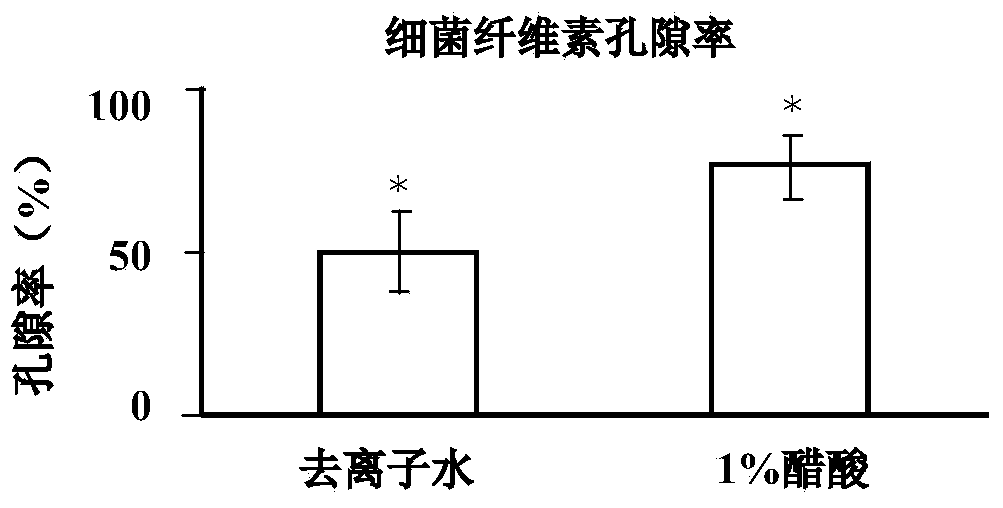

[0041] Example 1 - Bacterial cellulose film porosity measurement

[0042] Bacterial cellulose treated with deionized water: 2.5cm 2 Bacterial cellulose film pieces were soaked in 50mL deionized water for 12h.

[0043] 1% acetic acid treated bacterial cellulose: 2.5cm 2 Bacterial cellulose film blocks were soaked in 50mL of 1% acetic acid solution for 12h.

[0044] Freeze-drying the bacterial cellulose: Take out the soaked bacterial cellulose, pre-freeze it at -80°C for 4 hours, and then dry it in a freeze dryer at -76°C with a vacuum pressure of 10 Pa for 48 hours to obtain a dried bacterial cellulose film.

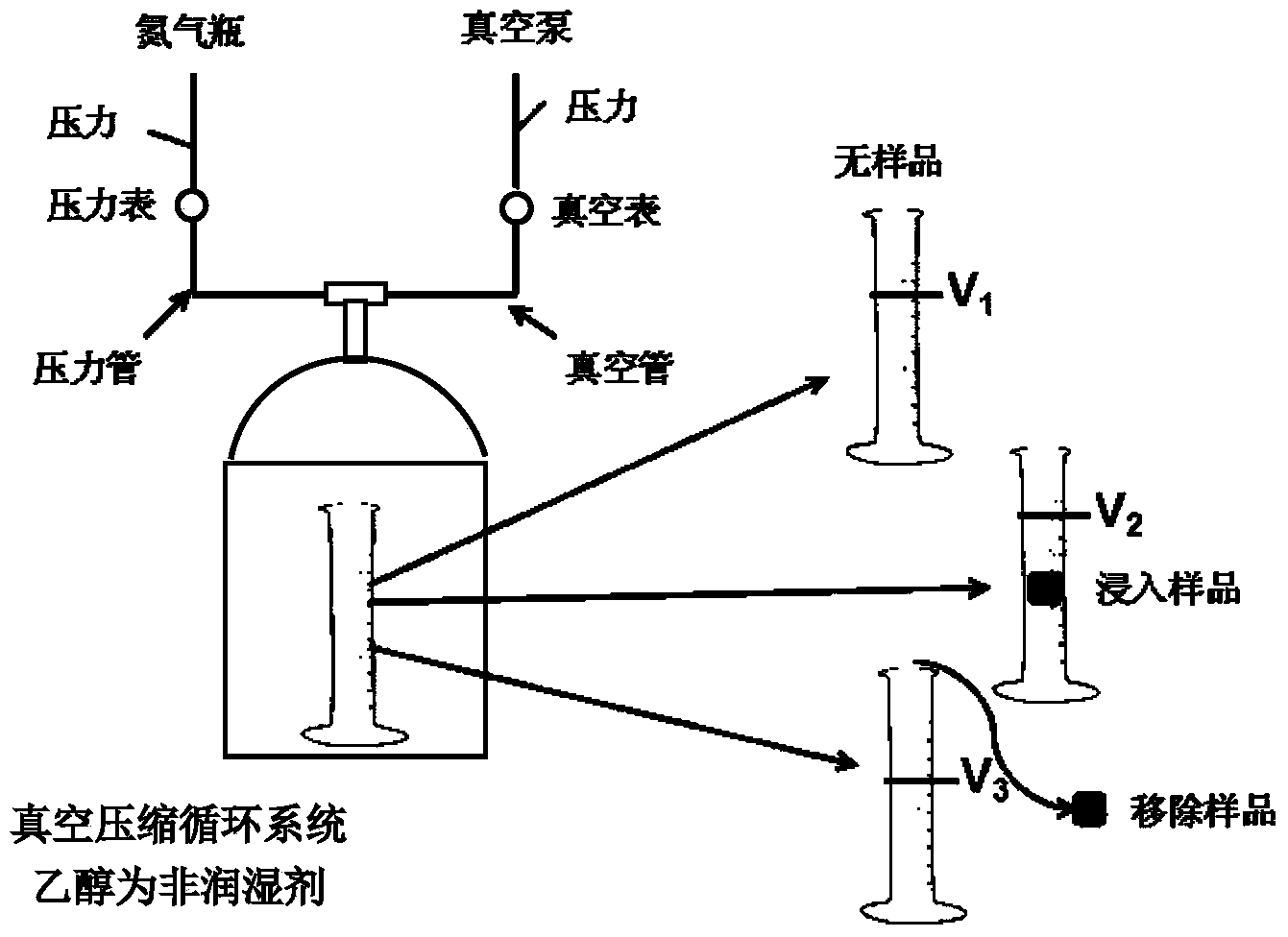

[0045] Porosity measurement: Firstly, 50 mL of ethanol was loaded into the graduated cylinder in the vacuum pressure vessel, and the bacterial cellulose film blocks treated with deionized water and 1% acetic acid were respectively immersed in ethanol. Start the vacuum compression cycle, wherein the vacuum pressure is 50 Pa for 10 seconds, and the pressurization press...

Embodiment 2

[0048] Example 2 - Regenerated silk protein porosity measurement

[0049] Fabrication of three-dimensional scaffolds from regenerated silk protein: first, PTFE cylinders were soaked in 5.8% (w / v) regenerated silk protein aqueous solution for 5 to 6 minutes, and 15% methanol solution was added to form a regenerated silk protein gel. The silk protein gel was pre-frozen at -80°C for 4 hours, and then dried at -76°C in a freeze dryer with a vacuum pressure of 10 Pa for 48 hours, and freeze-dried to obtain a three-dimensional scaffold of regenerated silk protein.

[0050] Porosity measurement: Firstly, 50 mL of n-hexane was filled into the graduated cylinder in the vacuum pressure vessel, and the three-dimensional scaffold of regenerated silk protein was immersed in n-hexane. Start the vacuum compression cycle, wherein the vacuum pressure is 50 Pa for 10 seconds, and the pressurization pressure is 0.10 MPa for 10 seconds, and the cycle is about 5 minutes to make n-hexane squeeze ...

Embodiment 3

[0053] Example 3 - Porosity measurement of hydroxyapatite-polylactic acid composites

[0054] Fabrication of the composite material: Take 10 mL of the polylactic acid-hydroxyapatite-dioxane mixture and add it into a 30 mL beaker, and preheat it to 50°C. Quickly transfer the beaker containing the mixed solution to the refrigerator to solidify the solvent in the mixed solution for 2 hours to induce solid-liquid phase separation. Then liquid nitrogen was used to promote deep freezing of the solidified sample, and the frozen sample was freeze-dried for 4 days under the condition of 0.5 mmHg to obtain a hydroxyapatite-polylactic acid composite material.

[0055] Porosity measurement: Firstly, 50 mL of ethanol was filled into the graduated cylinder in the vacuum pressure vessel, and the hydroxyapatite-polylactic acid composite material was immersed in the ethanol. Start the vacuum compression cycle, wherein the vacuum pressure is 50 Pa for 10 seconds, and the pressurization press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com