Silicon-based gallium arsenide epitaxial material and device manufacturing equipment and manufacturing method

A silicon-based gallium arsenide and epitaxial material technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor device manufacturing, final product manufacturing, etc., can solve the problem of substrate transfer process pollution, large footprint, and high purification level requirements for clean workshops, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

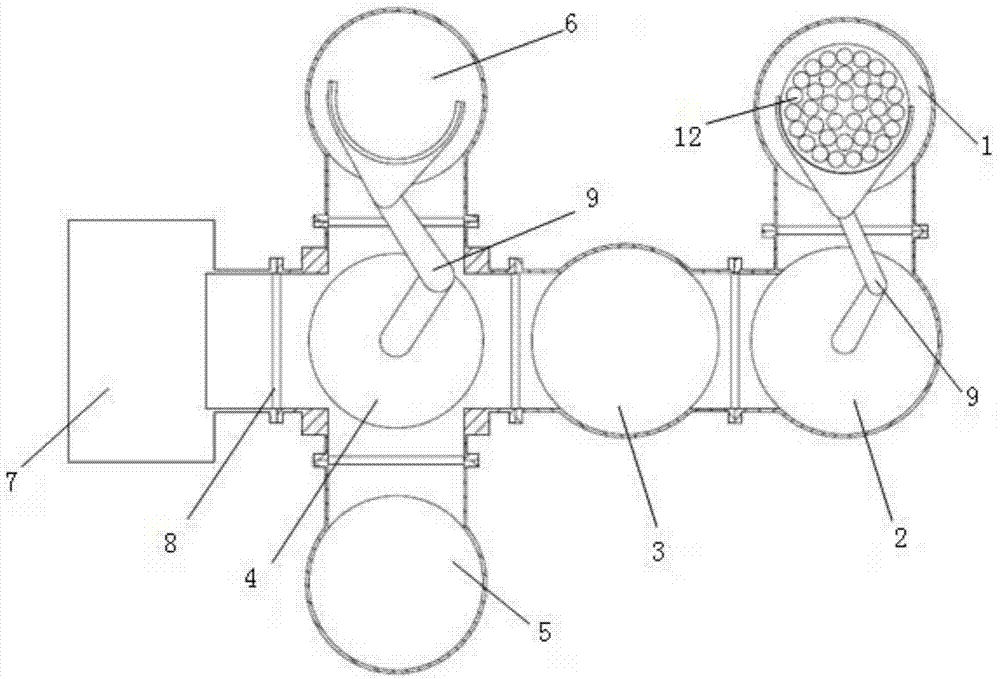

[0086] see figure 1 The silicon-based gallium arsenide epitaxial material and device manufacturing equipment include a UHVCVD reaction chamber 1; the UHVCVD reaction chamber 1 communicates with a vacuum transition chamber 2, and the vacuum transition chamber 2 communicates with a wafer buffer chamber 3, The wafer buffer chamber 3 is communicated with the central transfer chamber 4; the central transfer chamber 4 is also communicated with the heat treatment chamber 5, the MOCVD reaction chamber chamber 6 and the laminar flow hood 7; gate valves are arranged between the chambers communicated with each other 8. A gate valve 8 is also provided between the laminar flow hood 7 and the central transfer chamber 4; a vacuum manipulator 9 is provided in the central transfer chamber 4 and the vacuum transition chamber 2.

[0087] Wherein, the UHVCVD reaction chamber 1 is provided with a mechanical pump, a molecular pump and an ion pump, and the background vacuum degree of the UHVCVD reac...

Embodiment 2

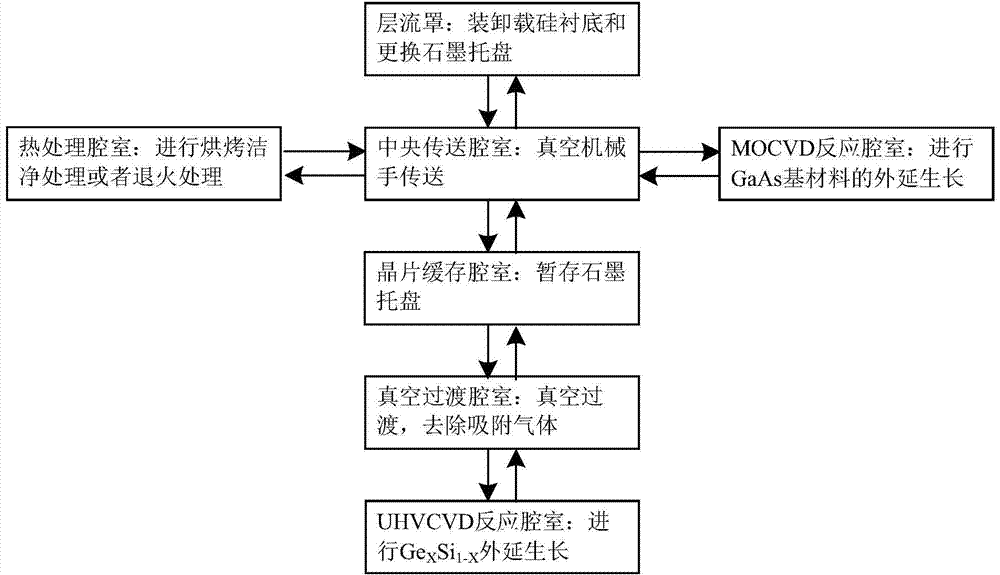

[0090] see figure 2 , based on the silicon-based gallium arsenide epitaxial material and device manufacturing method of the device described in embodiment 1, comprising the steps of:

[0091] (1) Use the vacuum manipulator in the central transfer chamber to transfer the graphite tray carrying the silicon substrate from the laminar flow hood to the wafer buffer chamber:

[0092] ①Laminar flow hood loading: load the cleaned silicon substrate on the graphite tray in the laminar flow hood;

[0093] ②Central transfer chamber transfer: the vacuum manipulator in the central transfer chamber transfers the graphite tray carrying the silicon substrate from the laminar flow hood to the wafer buffer chamber for temporary storage and keeps the vacuum within 25mtorr;

[0094] (2) Transfer the graphite tray carrying the silicon substrate in the cache chamber to the vacuum transition chamber for vacuum transition of the silicon substrate, and remove the adsorbed gas on the silicon substrate...

Embodiment 3

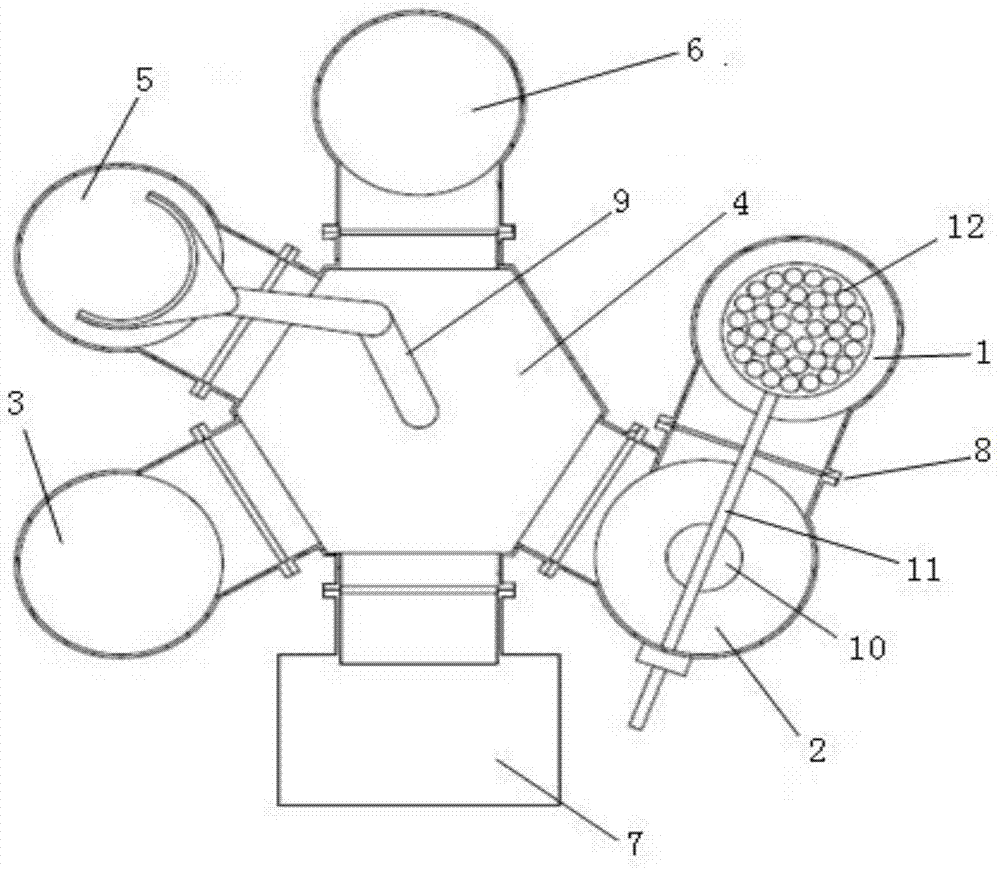

[0105] see image 3 The silicon-based gallium arsenide epitaxial material and device manufacturing equipment include a UHVCVD reaction chamber 1; the UHVCVD reaction chamber 1 communicates with a vacuum transition chamber 2, and the vacuum transition chamber 2 communicates with a central transfer chamber 4; The central transfer chamber 4 is also communicated with the wafer buffer chamber 3, the heat treatment chamber 5, the MOCVD reaction chamber 6 and the laminar flow cover 7; a gate valve 8 is arranged between the chambers communicated with each other, and the laminar flow cover 7 is connected to the central transfer chamber. A gate valve 8 is also provided between the chambers 4 ; a vacuum manipulator 9 is provided in the central transfer chamber 4 ; a bearing base 10 and a push rod 11 are provided in the vacuum transition chamber 2 .

[0106] Wherein, the UHVCVD reaction chamber 1 is provided with a mechanical pump, a molecular pump and an ion pump, and the background vacu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com