Processing method for reducing histamine in canned mackerel

A processing method and canning technology, which is applied in the processing field of reducing histamine in canned mackerel, can solve problems such as the difficulty of eliminating histamine, and achieve the effects of low cost, reducing histamine, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

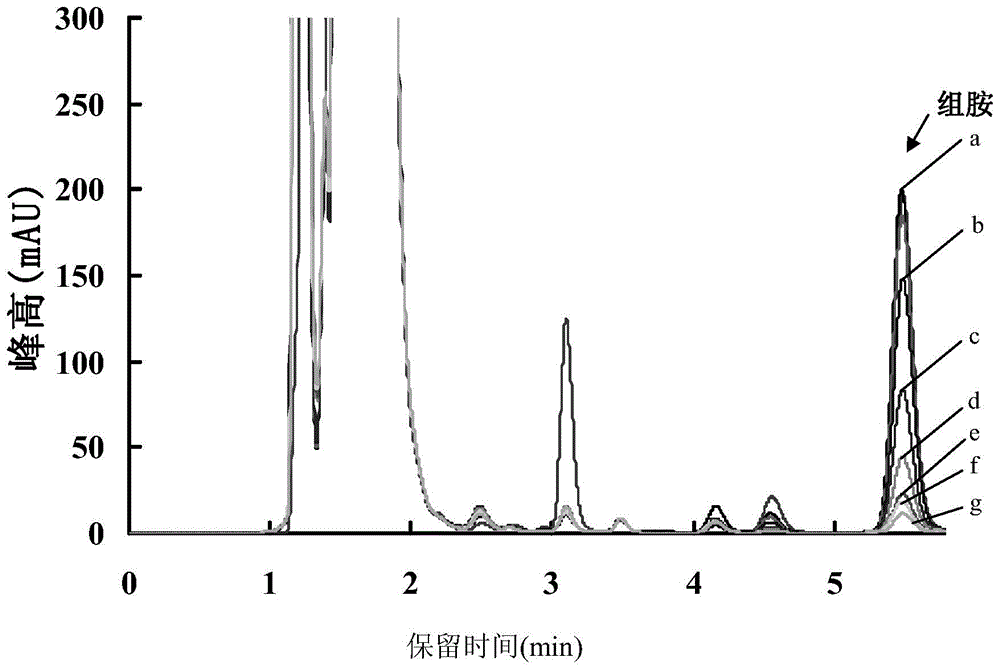

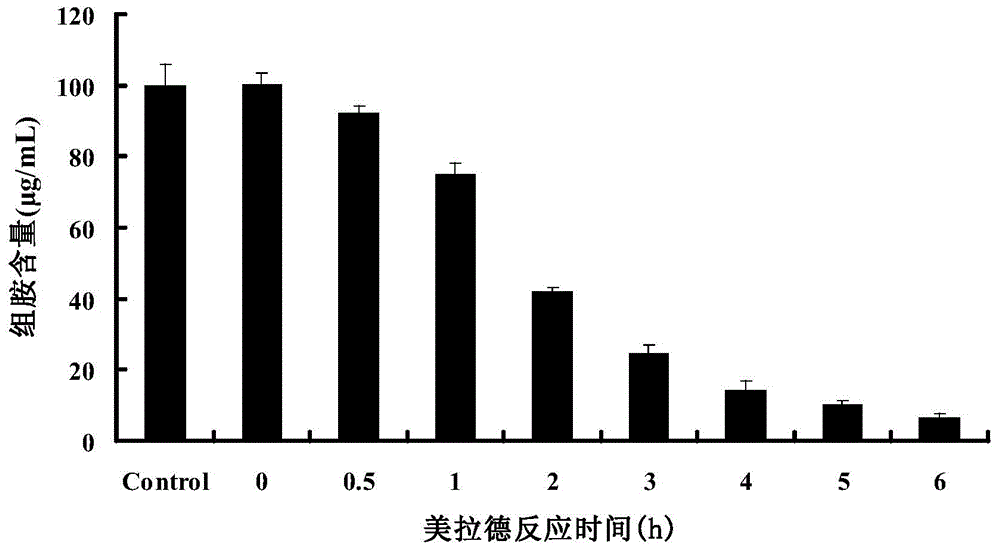

[0037] Embodiment 1: the influence of glucose Maillard reaction time on histamine standard substance

[0038] (1) Preparation of glucose solution and histamine standard solution. Prepared with 2m mol / L NaHCO 3 Glucose solution of 1.2 mol / L, and histamine standard solution with a concentration of 200 μg / mL was prepared with histamine dihydrochloride standard.

[0039] (2) The establishment of the Maillard reaction system. Glucose solution and histamine standard solution were mixed uniformly according to the volume ratio of 1:1, the final concentration of glucose solution was 0.6mol / L, the final concentration of histamine standard solution was 100 μg / mL, and the mixed solution was frozen and then freeze-dried.

[0040] (3) Maillard reaction of glucose and histamine standards. The freeze-dried samples were placed in a 60°C incubator for 0, 0.5, 1, 2, 3, 4, 5, and 6 hours, and the 100 μg / mL histamine standard solution was used as a control to detect the Maillard reaction after di...

Embodiment 2

[0041] Embodiment 2: adopt salt sugar water treatment (2.0% salt and 1.0% fructose) to reduce the processing method of histamine in canned mackerel, comprise the following steps:

[0042] (1) Thawing: Spray and thaw the frozen mackerel with clean water until the fish body temperature is 0°C;

[0043] (2) Pre-treatment: remove the head, tail and internal organs of the fish after thawing, and wash the blood stains, black film and gills in the abdominal cavity with clean water;

[0044] (3) Slicing and cleaning: the fish body is evenly cut into 2.0cm fish pieces, and washed repeatedly with clear water for 3 times to remove residual blood stains;

[0045] (4) Soaking: Soak the fish pieces in salt-sugar water (2.0% salt and 1.0% fructose) for 20 minutes, the soaking solution needs to be replaced each time, and the temperature is controlled below 10°C;

[0046] (5) Canning and cooking: before filling, the empty cans are sprayed and rinsed with 85°C hot water. During the canning pro...

Embodiment 3

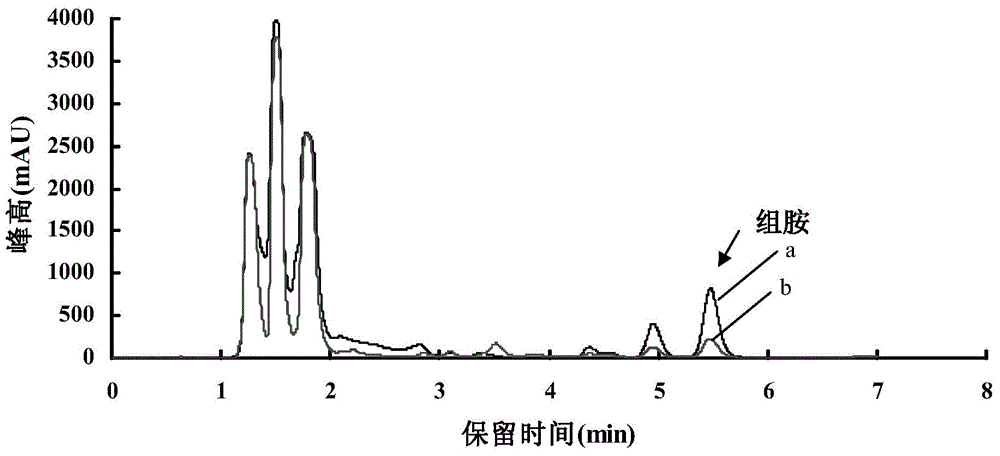

[0053] Embodiment 3: adopt the processing method of salt sugar water treatment (3% salt and 2.0% glucose) to reduce the histamine in canned mackerel, comprise the following steps:

[0054] (1) Thawing: Spray and thaw the frozen mackerel with clean water until the fish body temperature is 4°C;

[0055] (2) Pre-treatment: remove the head, tail and internal organs of the fish after thawing, and wash the blood stains, black film and gills in the abdominal cavity with clean water;

[0056] (3) Cutting and cleaning: the fish body is evenly cut into 1.5cm fish pieces, and washed repeatedly with clear water for 5 times to remove residual blood stains;

[0057] (4) Soaking: Soak the fish pieces in salt-sugar water (3% salt and 2.0% glucose) for 15 minutes, the soaking solution needs to be replaced each time, and the temperature is controlled below 10°C;

[0058] (5) Canning and cooking: before filling, the empty cans are sprayed and rinsed with 80°C hot water. During the canning proce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com