Method for preparing nitrogen-doped graphene with polydopamine as raw material

A nitrogen-doped graphene and polydopamine technology, applied in graphene, nano-carbon and other directions, can solve the problems of dangerous chemical reagents, difficult preparation and high cost, and achieves easy reaction process, simple and easy preparation method and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for preparing nitrogen-doped graphene with polydopamine as raw material described in this embodiment comprises the following steps:

[0028] 1) Preparation method of raw material polydopamine: put the cleaned nickel foam into 2 mg / mL freshly prepared dopamine solution (Tris-HCl 50mM, pH 8.5), and stir and polymerize at room temperature for 5 hours. Take out the nickel foam PDA-Ni with polydopamine on the surface, wash away the polydopamine physically adsorbed on the surface with ultrapure water, dry the PDA-Ni under an infrared lamp, and store it in a desiccator for later use.

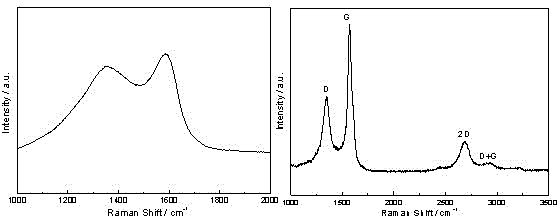

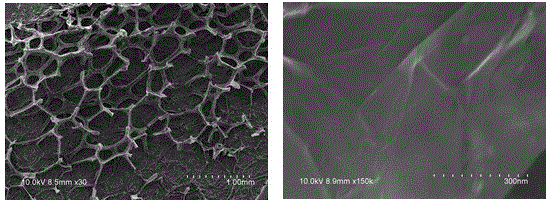

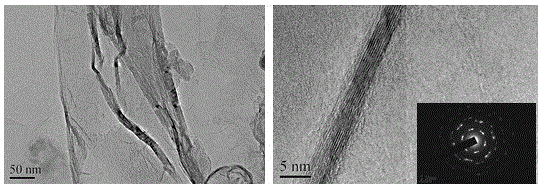

[0029] 2) Put the PDA-Ni into the crucible and place it in the middle heating area of the tube furnace, pass in argon gas with a purity ≥ 99% to remove oxygen, and after 30 minutes, raise the temperature to 800°C at a heating rate of 13°C / min, and keep for 1 h; then slowly lowered to room temperature, and a black product was formed at the bottom of the crucible——nitrogen-doped graph...

Embodiment 2

[0036] Compared with embodiment 1, the difference is only in:

[0037] Step 2 of this embodiment is: put the PDA-Ni into the crucible and place it in the middle heating area of the tube furnace, pass in nitrogen with a purity of ≥99% to remove oxygen, and after 30 minutes, raise the temperature to 700°C, kept for 1 h; then slowly lowered to room temperature, and nitrogen-doped graphene-coated nickel foam material NG-Ni was formed at the bottom of the crucible.

[0038] The quality of nitrogen-doped graphene (NG) obtained in this embodiment is similar to that of embodiment 1.

Embodiment 3

[0040] Compared with embodiment 1, the difference is only in:

[0041] Step 2 of this embodiment is: put PDA-Ni into the crucible and place it in the middle heating area of the tube furnace, pass in argon gas with a purity of ≥99% to remove oxygen, and after 30 minutes, heat up at a heating rate of 15°C / min Keep at 900°C for 1 h; then slowly lower to room temperature, and a nitrogen-doped graphene-coated nickel foam material NG-Ni is formed at the bottom of the crucible.

[0042] The quality of nitrogen-doped graphene (NG) obtained in this embodiment is similar to that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com