SiAlON ceramic containing crystalline phase Y4SiAlO8N, and preparation method and application thereof

A crystalline phase and ceramic technology is applied in the field of SiAlON ceramics containing crystalline phases and their preparation, which can solve the problems of decreased toughness of SiAlON ceramics, and achieve the effects of reducing material cost, prolonging service life, and improving high temperature stability and oxidation resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

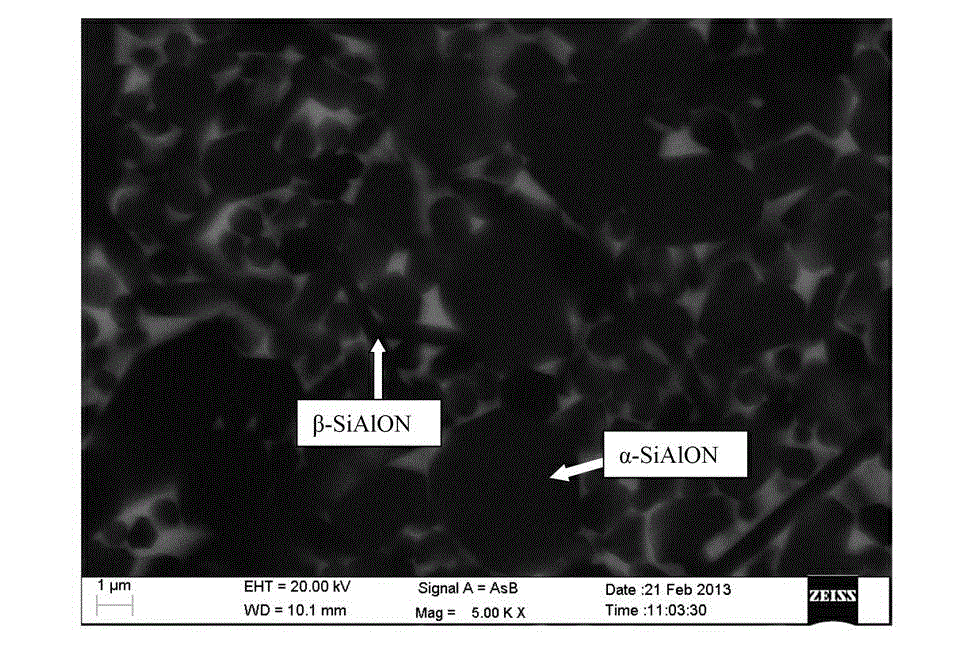

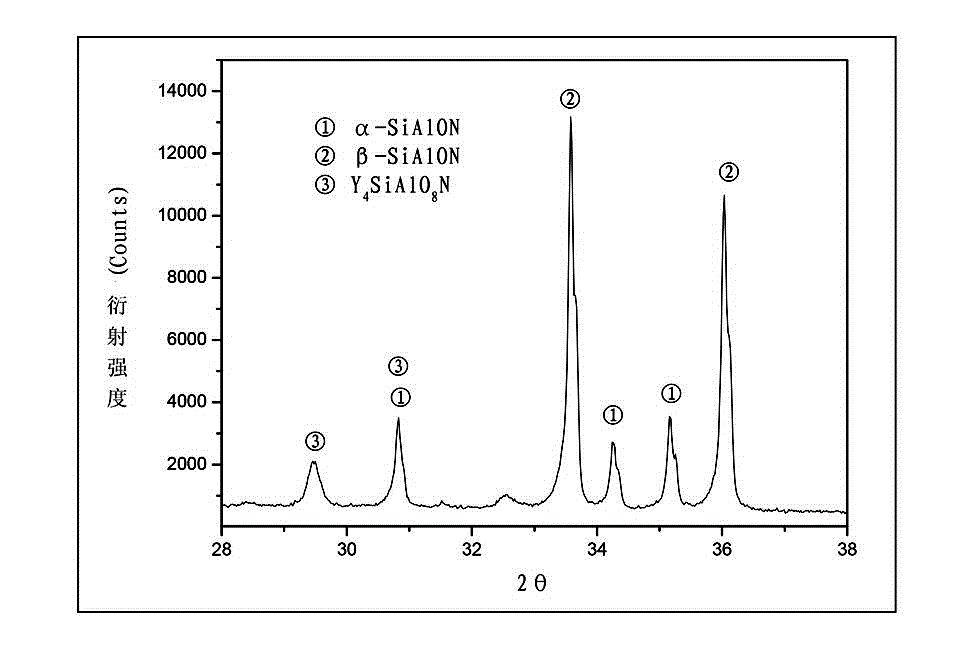

[0035] A kind of containing crystalline phase Y of the present invention 4 SiAlO 8 N SiAlON ceramics, in the crystal phase structure of SiAlON ceramics, SiAlON is the main phase crystal, and there is a crystal phase Y at the grain boundary of the main phase crystal 4 SiAlO 8 N, and the main phase crystal SiAlON is mainly a composite phase of α-SiAlON and β-SiAlON, and α-SiAlON contains α-Si 3 N 4 , β-SiAlON contains β-Si 3 N 4 (See figure 1 ). After X-ray diffraction of SiAlON ceramics in this example, the peak intensity of α-SiAlON near 2θ=34.2° is X, and the peak intensity of β-SiAlON near 2θ=33.5° is Y, Y 4 SiAlO 8 The peak intensity Z of N around 2θ=29.4°, and Y / X=4.79, Z / X=0.79.

[0036] The preparation method of the present embodiment SiAlON ceramics, comprises the following steps:

[0037] (1) According to Si powder 67wt%, α-Si 3 N 4 Powder 12wt%, Al 2 o 3 Powder 4wt%, AlN powder 8.5wt%, Y 2 o 3 Powder 8.5wt% weighed, the above powder particle size D 50...

Embodiment 2

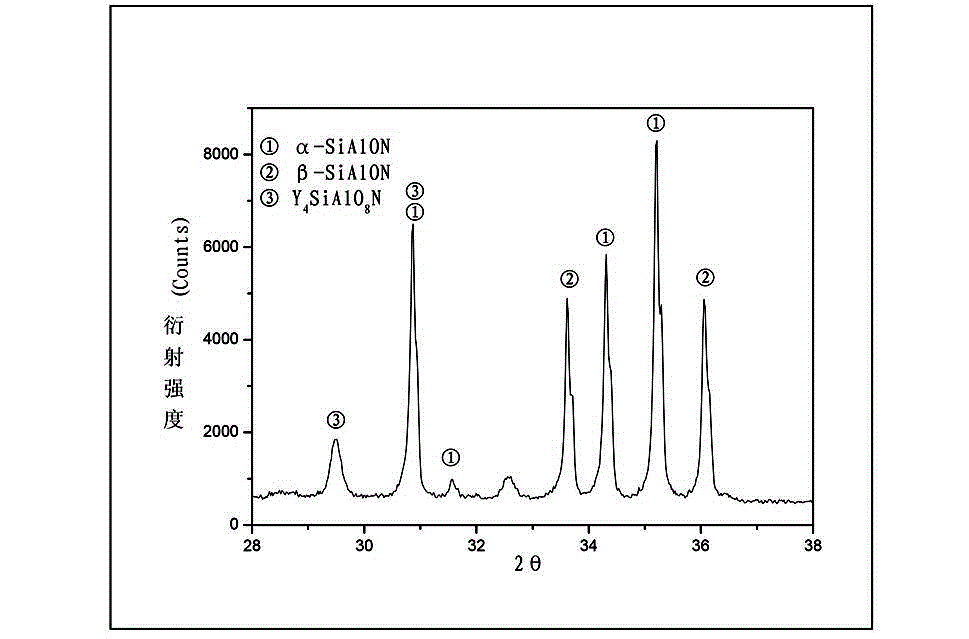

[0043] A kind of containing crystalline phase Y of the present invention 4 SiAlO 8 N SiAlON ceramics, in the crystal phase structure of SiAlON ceramics, SiAlON is the main phase crystal, and there is a crystal phase Y at the grain boundary of the main phase crystal 4 SiAlO 8 N, and the main phase crystal SiAlON is mainly a composite phase of α-SiAlON and β-SiAlON, and α-SiAlON contains α-Si 3 N 4 , β-SiAlON contains β-Si 3 N 4 (see figure 1 ). After X-ray diffraction of SiAlON ceramics in this example, the peak intensity of α-SiAlON near 2θ=34.2° is X, and the peak intensity of β-SiAlON near 2θ=33.5° is Y, Y 4 SiAlO 8 The peak intensity Z of N around 2θ=29.4°, and Y / X=0.84, Z / X=0.32.

[0044] The preparation method of the present embodiment SiAlON ceramics, comprises the following steps:

[0045] (1) According to Si powder 67wt%, α-Si 3 N 4 Powder 12wt%, Al 2 o 3 Powder 4wt%, AlN powder 8.5wt%, Y 2 o 3 Powder 8.5wt% weighed, the above powder particle size D 50...

Embodiment 3

[0051] A kind of containing crystalline phase Y of the present invention 4 SiAlO 8 N SiAlON ceramics, in the crystal phase structure of SiAlON ceramics, SiAlON is the main phase crystal, and there is a crystal phase Y at the grain boundary of the main phase crystal 4 SiAlO 8 N, and the main phase crystal SiAlON is mainly a composite phase of α-SiAlON and β-SiAlON, and α-SiAlON contains α-Si 3 N 4 , β-SiAlON contains β-Si 3 N 4 (see figure 1 ). After X-ray diffraction of SiAlON ceramics in this example, the peak intensity of α-SiAlON near 2θ=34.2° is X, and the peak intensity of β-SiAlON near 2θ=33.5° is Y, Y 4 SiAlO 8 The peak intensity Z of N near 2θ=29.4°, and Y / X=0, Z / X=0.32.

[0052] The preparation method of the present embodiment SiAlON ceramics, comprises the following steps:

[0053] (1) According to Si powder 54.4wt%, α-Si 3 N 4 Powder 9.6wt%, Al 2 o 3 Powder 4.5wt%, AlN powder 19.5wt%, Y 2 o3 Powder 12wt% weighed, the above powder particle size D 50 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com